Combustible sold waste pyrolysis gasification-swirl-flow combustion system

A pyrolysis gasification and combustion system technology, applied in combustion methods, combustion types, incinerators, etc., can solve problems such as land and groundwater pollution, harm to human living environment, and impact on production and life, reducing consumption, combustible solids, etc. The effect of large amount of waste pyrolysis gas and complete reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

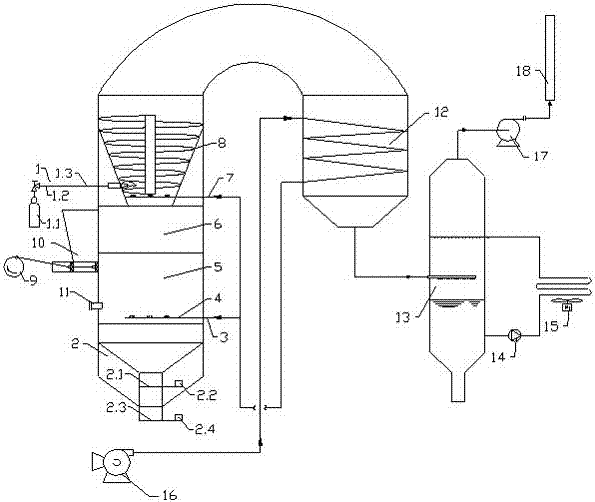

[0045] see figure 1 , the present invention relates to a combustible solid waste pyrolysis gasification-swirl combustion system, which includes a pyrolysis device, an ever-burning lamp 1, an automatic feeding device 9, a silo 10, an air preheater 12, and a flue gas quenching spray device 13. Circulating water pump 14, air cooler 15, blower 16, induced draft fan 17 and chimney 18.

[0046] The pyrolysis device includes an ash removal device 2 , an air distribution plate 4 , a heating reaction chamber 5 , a pyrolysis gasification chamber 6 and a swirl combustion chamber 8 from bottom to top.

[0047] The permanent lamp 1 is arranged on the side of the swirl combustion chamber 8, and the permanent lamp includes a propane bottle 1.1, a pressure reducing valve 1.2 and a fire detector 1.3, and the outlet of the propane bottle 1.1 is connected to the swirl combustion chamber 8, and a fire is arranged on the connecting pipeline of the two. Check 1.3, the outlet of propane bottle 1.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com