Micropressure self-discharge efficient and energy-saving wood drying device, and drying method

A high-efficiency, energy-saving, wood drying technology, used in wood drying, drying gas arrangement, drying solid materials, etc., can solve the problems of long drying time, difficult processing, and high drying energy consumption, and achieve good drying uniformity and drying energy consumption. The effect of reducing, increasing the drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

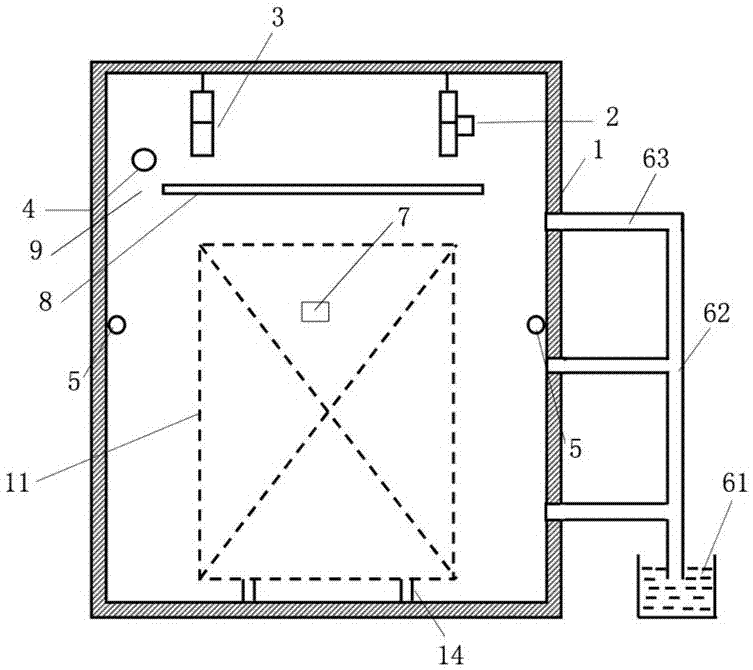

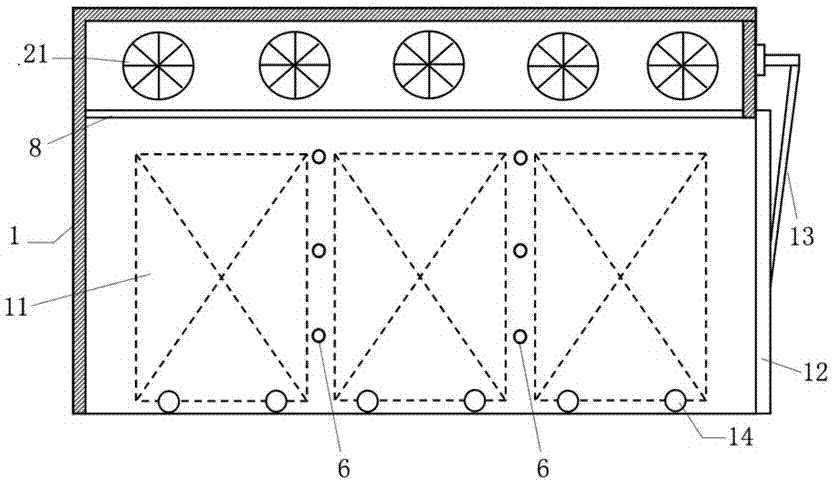

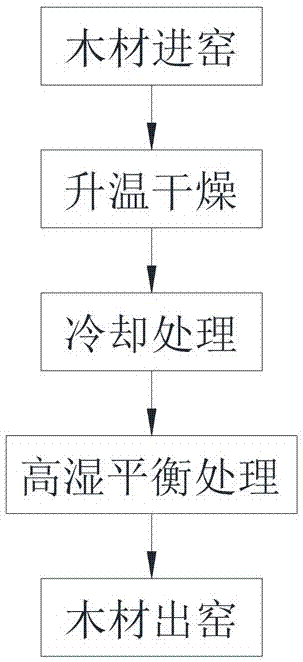

[0039] Such as Figure 1 to Figure 3 As shown, the first embodiment of the micro-pressure self-drainage type wood high-efficiency energy-saving drying method of the present invention is carried out with the above-mentioned micro-pressure self-drainage type wood high-efficiency energy-saving drying device, comprising the following steps:

[0040] S1: Wood enters the kiln: stack the wood in the wood drying area 11 of the kiln body 1 in the form of stacking;

[0041] S2: Heating and drying: Turn on the fan unit 2, the heating unit 3 and the steaming unit 4, and use the gradual temperature rise method to dry the wood. First, the temperature is raised to 40-60 °C at a heating rate of 15 °C / h, and the temperature is kept for 1-2 hours. Let the wood fully heat through; then raise the temperature to 100°C at a heating rate of 20°C / h, and keep it warm for 1-2 hours. During the heating process, the humidity in the drying room is kept above 95%. When the humidity reaches 95%, turn off the ...

Embodiment 2

[0049] Taking the yew sawn timber with an initial moisture content of 57% as an example, the yew sawn timber with a length of 1.0m, a width of 180mm, a thickness of 22mm, and an initial moisture content of 57% shall be oiled according to the LY / T1068-2012 standard. The fir sawn timber is stacked, the height of the pile is 2.2m, the width of the pile is 2.4m, the section size of the spacer is 25mm (thickness) × 30mm (width), and the length is 2.5m, and temperature and humidity sensors are placed in the pile as required 7. Use the bottom rail 14 to send the pile of wood to the wood drying area 11 of the kiln body 1, close the kiln door 12, open the axial flow fan 21, the heating assembly 3 and the steam spraying assembly 4, and adopt the gradual heating method to dry the wood. Raise the temperature to 50°C at a heating rate of 15°C / h and keep it warm for 2 hours to fully heat the wood, then raise the temperature to 100°C at a heating rate of 20°C / h and keep it warm for 2 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com