Fuel gas generator capable of quickly inflating underwater ordnance floating system

A gas generator, fast technology, applied in the direction of weapon accessories, ammunition test, ammunition, etc., can solve the problems affecting the ballistic accuracy, etc., achieve the effect of inflatable speed block, easy installation and sealing, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

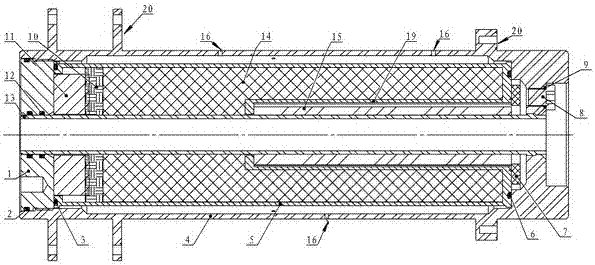

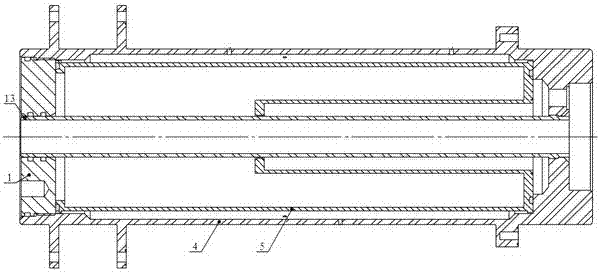

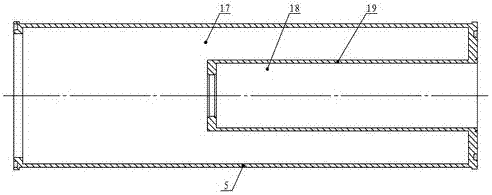

[0033] Refer to attached figure 1, the primer 7 and the seal ring 6 that 5g black powder and potassium boron nitrate are housed are bonded on the base plate of the filter device 5, and the 100g low-temperature gas generating agent drug strip 15 is evenly bonded on the combustion chamber 18 inner walls. Put the bottom plate of the assembled filter device 5 downward into the generator, put 800g of granular low-temperature gas-generating agent particles 14 into the working room, and fill up the remaining space of the working room with a sponge pad 10 . Put the sealing ring 3 into the filter device, and after the sealing rings 2 and 12 are installed in the end cover 1, assemble the end cover 1 with the shell by using the assembly hole of the end cover. Fitting the igniter 8 onto the bottom of the generator completes the generator assembly.

[0034] In a 58L airtight container, an electric current is used to stimulate the ignition test. data such as Figure 5 shown. The maximum...

Embodiment 2

[0036] Refer to attached figure 1 12g igniting drug ring and sealing ring 6 are bonded on the bottom plate of filter device 5, and 80g low-temperature gas generating agent drug strip 15 is evenly bonded on the inner wall of the combustion chamber. Put the bottom plate of the assembled filter device 5 downwards into the generator, put 620g of granular low-temperature gas-generating agent particles 14 into the working room, put the working chamber cavity adjustment pad 11 into the working room, and put the gas-generating drug and the pad into the working room. Sponge pads 10 are used to isolate the blocks. Put the seal ring 3 into the filter device, and after the seal rings 2 and 12 are installed in the end cover 1, use the end cover assembly hole to assemble the end cover and the shell. Fit the igniter onto the bottom of the generator to complete the generator assembly.

[0037] In a 58L airtight container, an electric current is used to stimulate the ignition test. data suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com