Method for determining smooth shaped charge blasting parameter in stratified rock mass tunnel

A determination method and rock mass technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as smooth surface blasting overexcavation, uneven contour surface, etc., and achieve the effect of simple and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

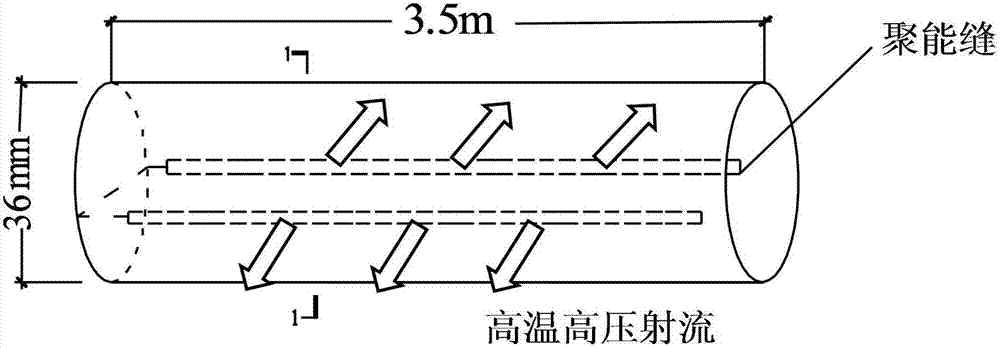

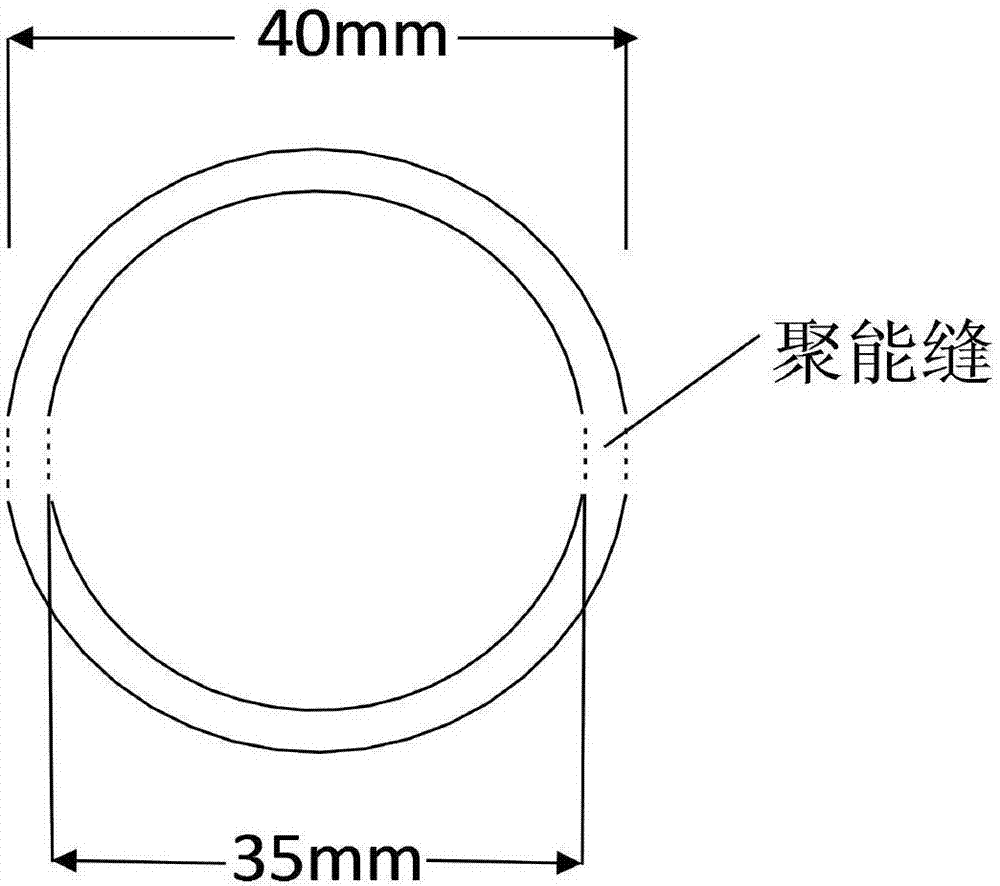

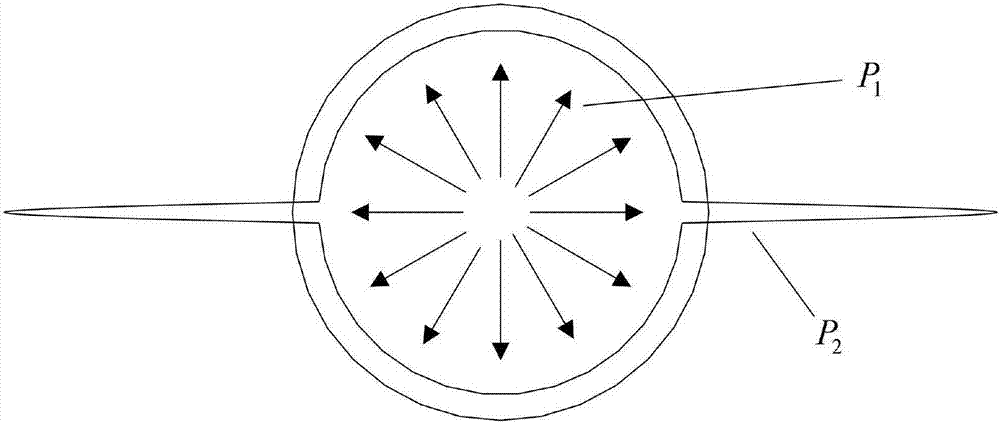

[0075] A method for determining the parameters of tunnel energy-gathering smooth surface blasting in the present invention will be described in detail below in conjunction with the accompanying drawings and specific algorithms. The blastholes (peripheral holes) on the contour line of the energy-concentrating smooth surface blasting are the last to be detonated after the blasting of other blastholes. The peripheral holes are charged with energy-concentrating tubes, which concentrate the explosion energy of the explosives and make the rock mass explode along the excavation contour line. The present invention carries out the energy-gathering seam cutting ( Figure 1-2 ), energy-gathering slit blasting refers to the energy released during the explosion of explosives to gather energy-gathering flow along the slit slots, and generate high-pressure, high-speed high-temperature jets at the slit slots, so that it has super penetrating The ability to cut the rock to obtain a smoother pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com