Semiconductor structure, self-supporting gallium nitride layer and preparation methods therefor

A gallium nitride layer and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as poor universality, cracking of gallium nitride epitaxial layers, low yield, etc., to suppress excessive decomposition , the effect of improving growth quality and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

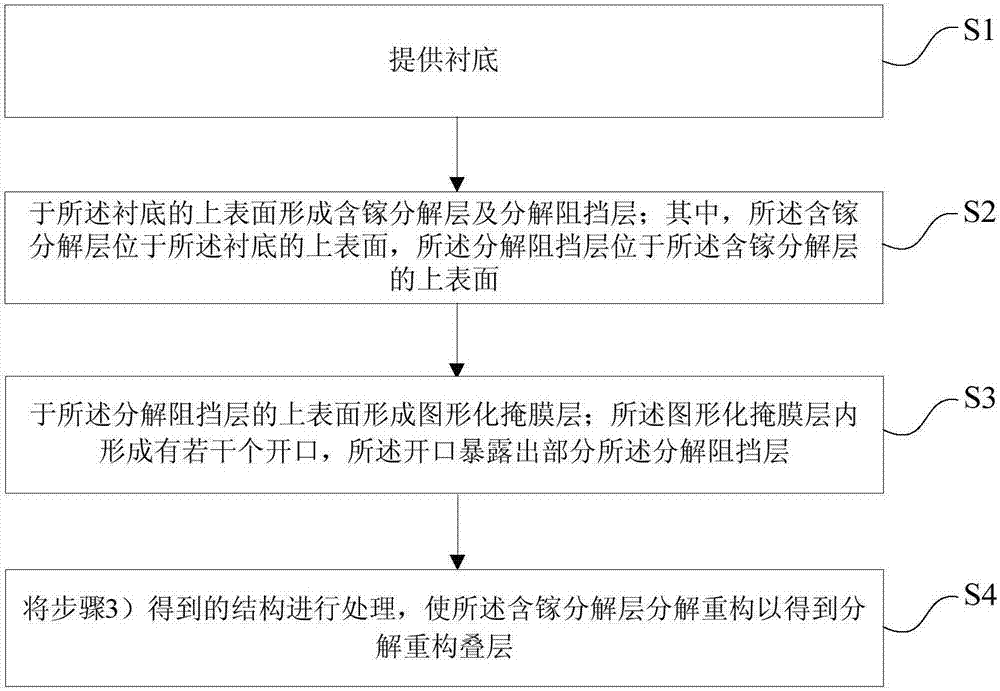

[0068] see figure 1 , the invention provides a method for preparing a semiconductor structure, the method for preparing a semiconductor structure includes the following steps:

[0069] 1) Provide the substrate;

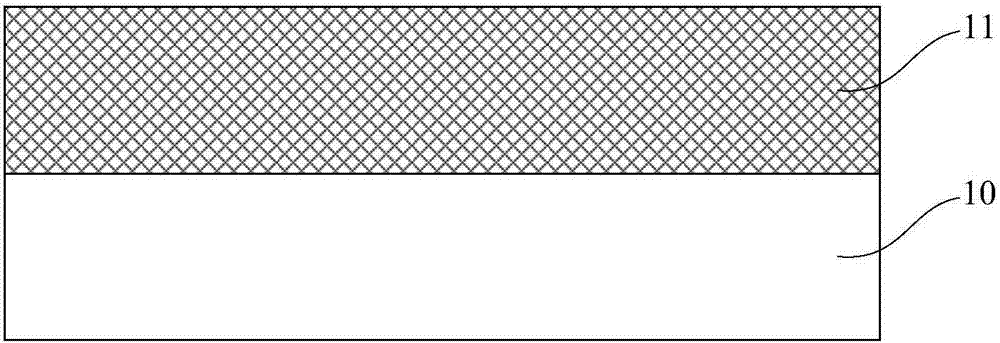

[0070] 2) forming a gallium-containing decomposition layer and a decomposition barrier layer on the upper surface of the substrate; wherein, the gallium-containing decomposition layer is located on the upper surface of the substrate, and the decomposition barrier layer is located on the gallium-containing decomposition layer upper surface;

[0071] 3) forming a patterned mask layer on the upper surface of the structure obtained in step 2); several openings are formed in the patterned mask layer, and the openings expose part of the decomposition barrier layer;

[0072] 4) Process the structure obtained in step 3) to decompose and reconstruct the gallium-containing decomposed layer to obtain a decomposed and reconstructed stack, wherein the decomposed and reconstructe...

Embodiment 2

[0114] Please combine Figure 1 to Figure 7 refer to Figure 9 to Figure 15 , the present invention also provides a method for preparing a semiconductor structure. The method for preparing a semiconductor structure described in this embodiment is substantially the same as the method described in Embodiment 1. The difference between the two is that step 2 of Embodiment 1 The gallium-containing decomposing layer 11 formed in ) is located on the upper surface of the substrate 10, the decomposition barrier layer 12 is located on the upper surface of the gallium-containing decomposing layer 11, and the thickness of the gallium-containing decomposing layer 11 can be is but not limited to 100nm-6μm; preferably, the thickness of the gallium-containing decomposition layer 11 is 150nm-1000nm; more preferably, the thickness of the gallium-containing decomposition layer 11 is 200nm-900nm; more preferably, the The thickness of the gallium-containing decomposition layer 11 is 300nm-800nm; ...

Embodiment 3

[0118] Please combine Figure 1 to Figure 7 refer to Figure 16 and Figure 17 , the present invention also provides a method for preparing a semiconductor structure. The method for preparing a semiconductor structure described in this embodiment is substantially the same as the method described in Embodiment 1. The difference between the two is that the semiconductor structure of this embodiment Compared with the preparation method described in Example 1, a method for forming nitrogen on the upper surface of the substrate 10 is added between step 1) and step 2) of the preparation method described in Example 1. The step of forming the aluminum nitride layer 15, the aluminum nitride layer 15 is located between the substrate 10 and the gallium-containing decomposed layer 11; that is, the aluminum nitride layer 15 is first formed on the upper surface of the substrate 10 , and then form the gallium-containing decomposed layer 11 on the upper surface of the aluminum nitride layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com