Linear generator apparatus using cold water and hot water to generate power

A linear generator, cold and hot water technology, applied in the field of energy, can solve the problems of high power generation cost and low energy conversion efficiency, achieve low power generation cost, high energy conversion efficiency, and overcome the effect of high power generation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

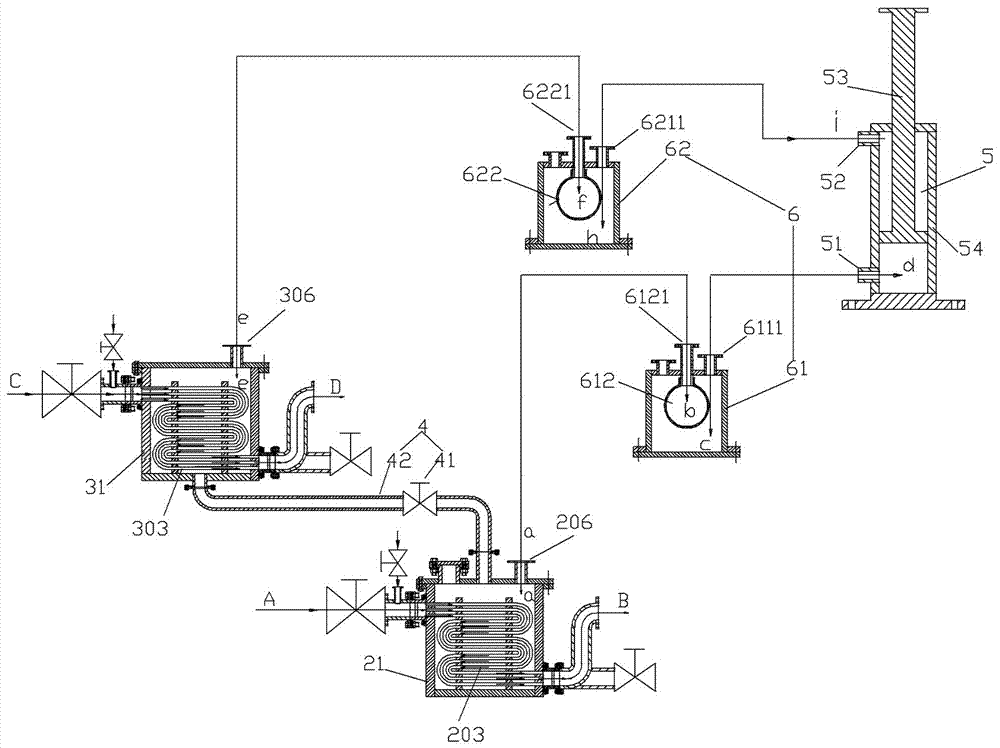

[0038] like figure 1 , 2 , 3, and 10, where figure 1 , 2 3. Three views of the hot chamber 21. The hot chamber 21 includes a hot chamber upper cover 207 and a hot chamber box body 202. The hot chamber upper cover 207 is provided with a hot chamber connecting pipe 204 and a hot chamber working fluid injection pipe 205. , hot chamber working fluid inlet and outlet pipe 206, the hot chamber heat transfer pipe 203 and the stabilizing plate 220 are arranged inside the hot chamber box body 202, and the hot chamber heat transfer pipe 203 includes a hot water inlet 208 and a hot water inlet through the wall of the hot chamber. The water outlet 209 is provided with a hot chamber working medium discharge pipe 201 on the side wall, and a hot water inlet tank 210 and a hot water inlet pipe 211 connected thereto, a hot water outlet tank 212 and a hot water outlet tank 212 are arranged on the outer wall of the hot chamber 21 The hot water discharge pipe 213 communicated with it, the hot ...

Embodiment 2

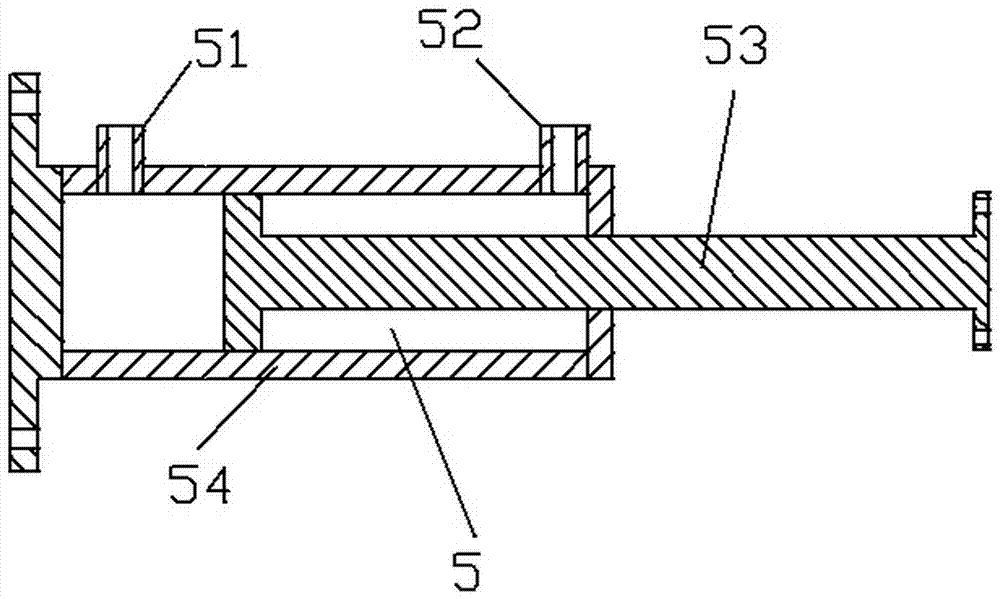

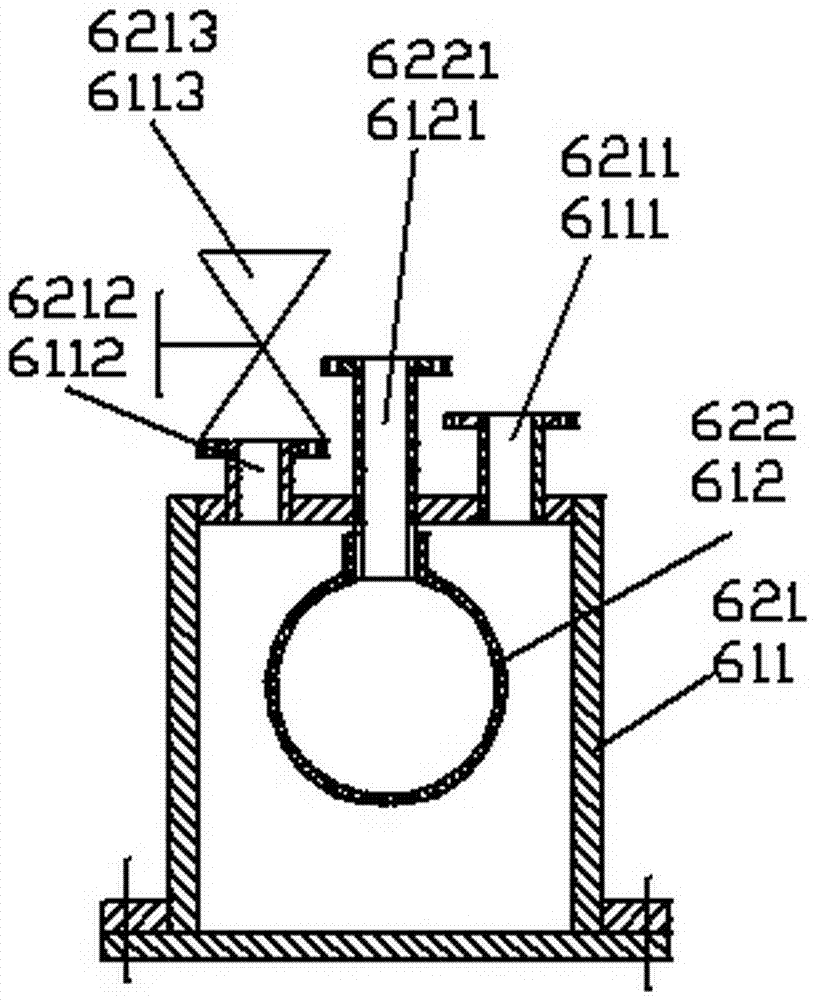

[0054] like Figure 11 As shown, it is a schematic diagram of the preferred structure of Embodiment 1. The present invention includes a linear generator 7 and a driving device for driving the linear generator 7 to generate electricity, and the linear generator 7 includes the linear generator stator 71 described in the linear generator. The motor 72; the driving device includes a cold and hot water supply device 1, a hot chamber 21 and a cold chamber 31 filled with a first fluid working medium, a regenerator 4 communicating with the hot chamber 21 and the cold chamber 31, and the A double-acting hydraulic cylinder 5 connected to the hot chamber 21 and the cold chamber 31, the double-acting hydraulic cylinder 5 is connected to the linear generator 7 through a hydraulic rod 53; 203, the hot chamber heat transfer pipe 203 runs through the outer wall of the hot chamber 21; the cold chamber 31 is provided with a cold chamber heat transfer pipe 303, and the cold chamber heat transfer...

Embodiment 3

[0069] like Figure 12 As shown, it is also a schematic diagram of the preferred structure of Embodiment 1. The preferred mode and power generation process are basically the same as those of Embodiment 2, and the similarities will not be described here. The difference is that in Embodiment 2, the hydraulic cylinder 5, the linear generator 7 and the spring device 8 are installed vertically, and the inward movement of the hydraulic rod 53 and the linear generator mover 72 depends on the contraction force F2, the hydraulic rod 53 and the linear generator mover 72 themselves Gravity and spring force; in this embodiment, the hydraulic cylinder 5, the linear generator 7 and the spring device 8 are installed horizontally, and a support wheel device 10 is added at the bottom of the linear generator mover 72, and the hydraulic rod 53 and the linear generator mover 72 are inward The movement depends on the contraction force F2 and the spring force. The purpose of this embodiment is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com