An energy-saving three-dimensional multi-layer intelligent plant factory

A three-dimensional multi-layer, energy-saving technology, applied in the direction of atomized materials, energy-saving measures, botanical equipment and methods, etc., can solve the problems of uneven temperature of three-dimensional multi-layer, high operating cost, large initial investment, etc., to reduce Running time and cost, saving investment, uniform temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

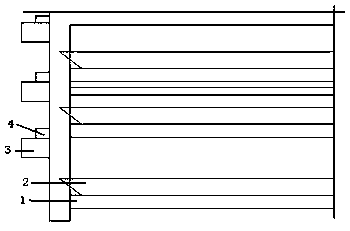

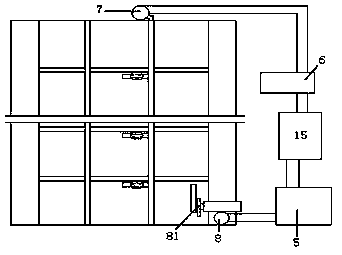

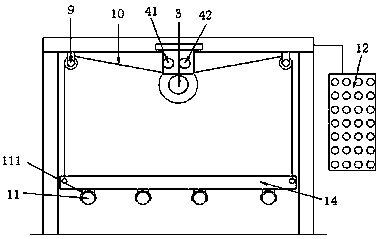

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, this specific embodiment adopts the following technical solutions: it includes a planting bed main frame 1, multi-layer planting tanks 2, planting grids, and an automatic circulation system for nutrient solution; the planting bed main frame 1 is provided with multi-layer planting tanks 2. The nutrient solution automatic circulation system, the bottom of each planting tank of the multi-layer planting tank 2 is provided with a galvanized steel pipe, and the galvanized steel pipe is composed of a vertical water supply pipe 7 and a vertical return water pipe 8. Multi-layer parallel galvanized steel pipes are connected to each other, and the indoor temperature is balanced up and down in the same cycle. A planting grid is installed above each layer of the multi-layer planting tank 2, and a supplementary light is installed on the top of the planting grid to automatically adjust Lifting frame, pulley 9 is all inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com