Manufacturing system and manufacturing process for stone-like ceramic tile with vivid stone imitation effect

A manufacturing system and manufacturing process technology, used in manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of unstable hair color in dark colors, not bright enough colors, and insufficient color, and achieve realistic reproduction of three-dimensional effects. , Good color and three-dimensional effect, overcoming the effect of insufficient color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

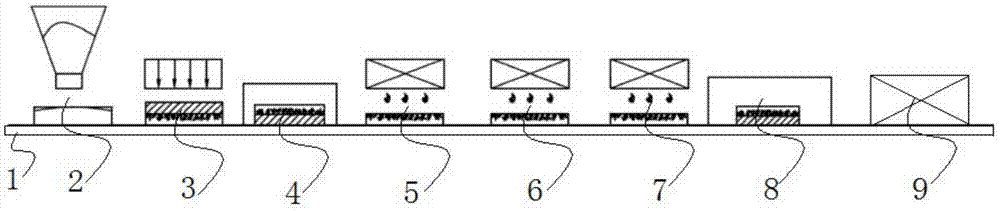

[0031] A system for manufacturing stone-like ceramic tiles with realistic stone-like effects, such as figure 1 As shown, it includes a distributing device 2, a pressing device 3, a biscuit firing device 4, a bottom layer glazing device 5, an inkjet printing device 6, a surface layer glazing device 7, a firing device 8, and a cutting and polishing device 9, which are sequentially connected by a conveyor belt 1. .

[0032] The distributing device 2 includes a micropowder unloading mechanism, a granule unloading mechanism and a line unloading mechanism, each unloading mechanism includes a storage hopper for storing micropowder raw materials, granular raw materials or line raw materials, and a discharge drum arranged below the storage hopper , and an outlet gate set at the outlet of the discharge drum to control the discharge volume. The pressing device 3 is a ceramic press, the biscuit firing device 4 is a bisque firing kiln, the firing device 8 is a firing kiln, and the cutting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com