Center cutter box repair technique of shield in upper-soft lower-hard ground under normal pressure

A hard formation, shield cutter head technology, applied in underground chambers, shaft linings, tunnel linings, etc., to achieve the effect of easy implementation, avoiding subsidence, and simple on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

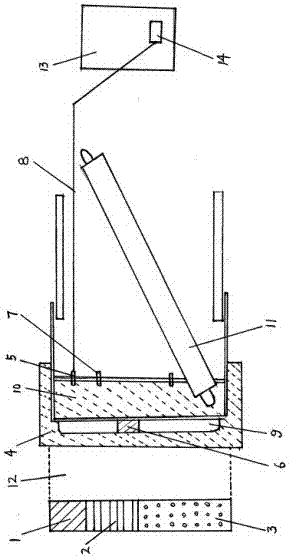

[0015] The present invention will be described in detail below based on the drawings:

[0016] A repair process for the center knife box of a shield machine in an upper soft and lower hard formation under normal pressure, including the following steps:

[0017] Step 1. When the shield cutterhead 9 is excavated to the excavation surface, the upper part is silt mixed with silt sand formation 1, the middle part is moderately weathered sandstone formation 2, and the lower part is slightly weathered sandstone formation 3, if the center cutter box 6 of the cutter head is damaged , When it needs to be replaced, stop the rotation of the shield cutter head;

[0018] The second step is to connect the radial hole ball valve 5 at the 11 o'clock position of the shield machine personnel compartment to the bentonite conveying pipe 8, and connect the other end of the bentonite conveying pipe 8 to the synchronous grouting pump 14, with a viscosity greater than 40 seconds The bentonite slurry replace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com