Flame-retardant polypropylene composition

一种聚丙烯组合物、阻燃性的技术,应用在阻燃性聚丙烯组合物领域,能够解决节能不优选、树脂组合物质量增加、损害树脂物性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~12

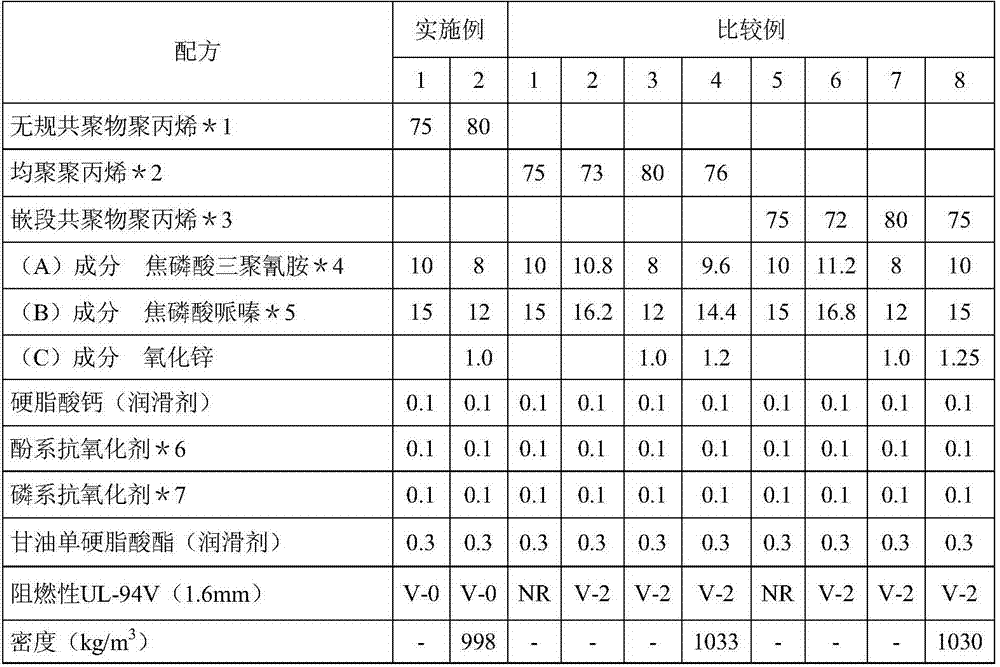

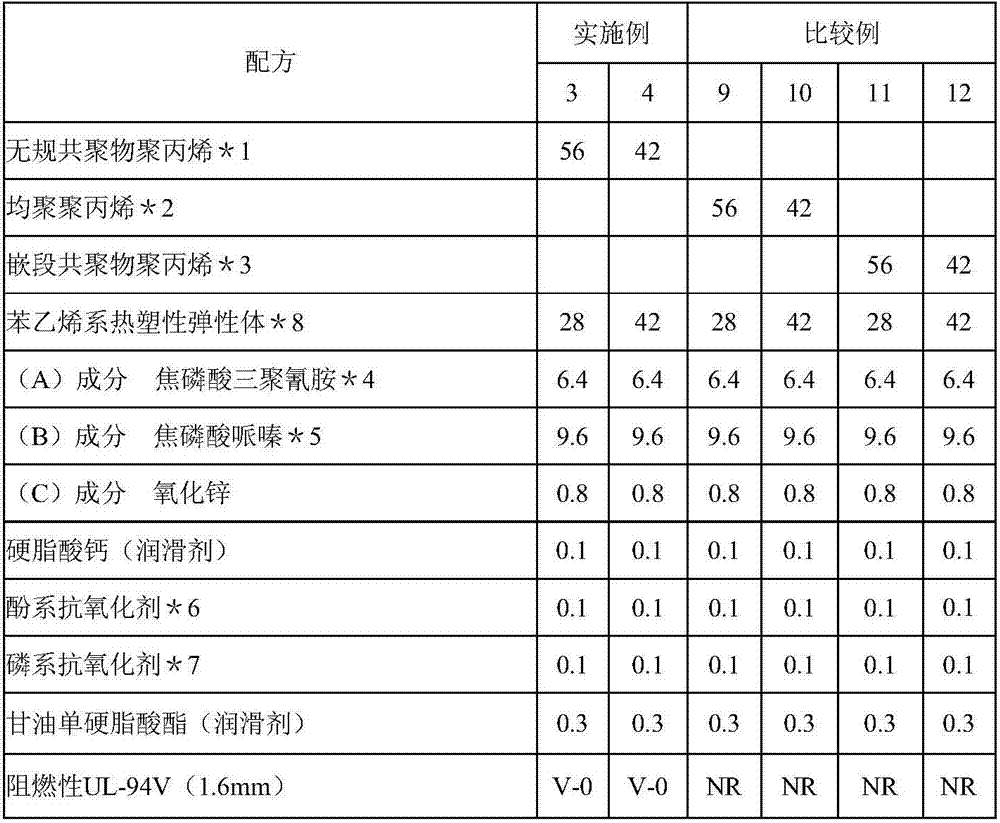

[0107] According to the ingredients described in the following Tables 1 and 2, a flame-retardant polypropylene composition was prepared, and then the flame-retardant polypropylene composition was extruded at 200 to 230°C to produce pellets, and the obtained pellets were used Injection molding was performed at 200° C. to obtain a test piece with a length of 127 mm, a width of 12.7 mm, and a thickness of 1.6 mm. Using this test piece, a UL-94V test was performed as a flame retardancy test by the following test method. The results are shown in Tables 1 and 2.

[0108] In addition, the mass and volume of the test piece of Example 2 were measured, and the density of the molded body was calculated by calculation. The results are shown in Table 1.

[0109] In the same manner, comparative examples were carried out according to the formulations described in Tables 1 and 2. In Comparative Examples, homopolypropylene and block copolymer polypropylene were used instead of the random co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com