Harvester divider device applicable to mixed crop harvesting

A technology of grain divider and harvester, which is applied to harvesters, external grain dividers, applications, etc., can solve the problems of unsatisfactory grain division effect, large loss of grain division, entanglement of straw, etc., so that it is not easy to hang grass, process Convenience, effect of reducing the loss of crop division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

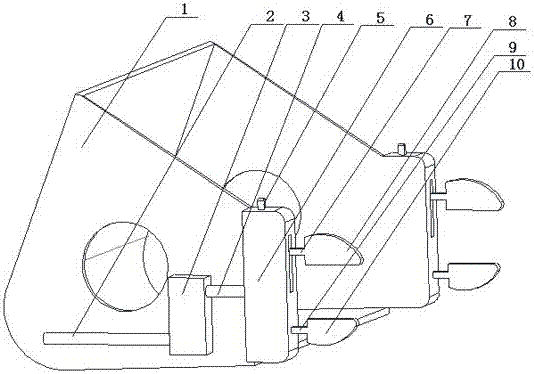

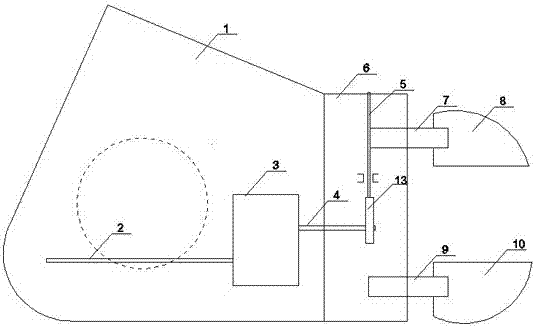

[0014] As shown in the figure, the specific implementation method is as follows:

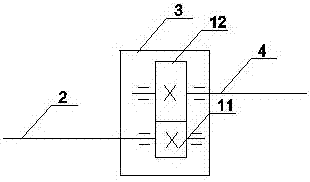

[0015] A grain divider device for a harvester suitable for harvesting miscellaneous grains, comprising a grain divider mechanism symmetrically arranged on both sides of the front end of the header frame 1, the grain divider mechanism includes a fixed box 6, a power mechanism, an upper grain divider 8 and a lower grain divider Device 10, described upper grain dividing device 8 and lower grain dividing device 10 all are the right-angled triangle structure that the hypotenuse is a circular arc, wherein the arc edge is the dividing blade for separating miscellaneous grains on the grain dividing device, and the dividing grain The overall surface of the device is smooth, without edges and corners, and is in the shape of a curved surface. The power mechanism includes: a power input shaft 2, a gearbox 3, a power output shaft 4, a cam 13 and a push rod 5. The gearbox 3 is provided with a large gear 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com