Clean and efficient gas fire extinguishing agent composition

A gas fire-extinguishing agent and technology of fire-extinguishing agent, which is applied in fire prevention equipment and other directions, can solve the problems of large storage volume of inert gas medium, limiting the use range of inert gas fire-extinguishing agent, and high boiling point of fire-extinguishing agent, so as to reduce the potential value of greenhouse effect and produce Low cost and no corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

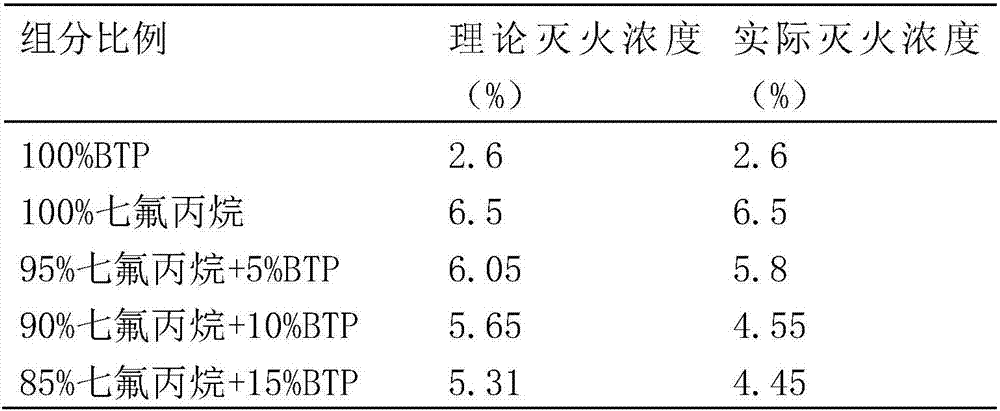

[0026] The composition of the composite gas fire extinguishing agent raw material of the present embodiment is: BTP+heptafluoropropane

[0027] 1. Test of fire extinguishing effect

[0028] 1.1 Experimental equipment:

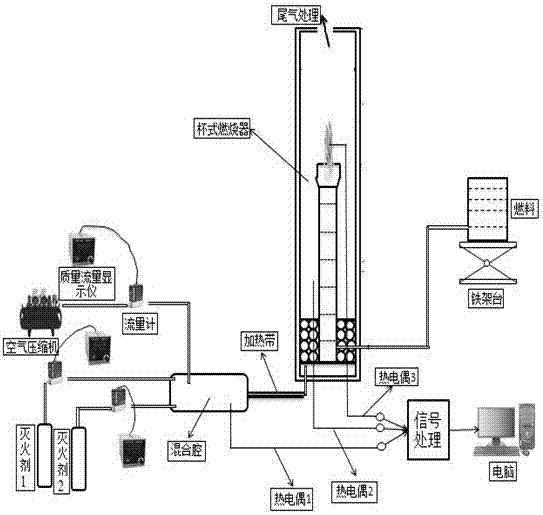

[0029] test platform such as figure 1 As shown, the main components include a cup burner, a fuel supply device, a fire extinguishing medium supply device and various measurement and control devices. The combustion cup of the cup burner is cylindrical, the material is heat-resistant glass, the outer diameter is 30mm, the wall thickness is 1.5mm, the edge chamfer of the top of the cup is 45°, and thermocouples are installed in the cup and the mixing chamber respectively. Thermocouple 1 can measure the temperature of the mixing chamber, thermocouple 2 is used to measure the temperature of the gas in the cup burner, and thermocouple 3 is used to measure the outer flame temperature of the fuel combustion flame. There is a fuel inlet near the bottom of the burner,...

Embodiment 2

[0041] The raw material ratio of the composite gas fire extinguishing agent of this embodiment is: pentafluoroethane+BTP

[0042] 1. Test of fire extinguishing effect:

[0043] Change the gaseous fire extinguishing agent in the test example into pentafluoroethane, and measure the fire extinguishing concentration of the gaseous fire extinguishing agent of embodiment 2 with the same equipment and operation steps of the test example 1.

[0044]

[0045] It can be seen from the experimental results that when 90% pentafluoroethane is mixed with 10% BTP to extinguish the fire, the theoretical calculation value of the fire extinguishing concentration without considering the synergy is 7.05%, while the experimentally measured fire extinguishing concentration is only 5.6%. This proves that the composite fire extinguishing medium formed by pentafluoroethane and BTP shows a good positive and synergistic fire extinguishing effect.

Embodiment 3

[0047] The raw material ratio of the composite gas fire extinguishing agent of this embodiment is: 1,1,2,2,3,3,4-heptafluorocyclopentane+BTP

[0048] 1. Test of fire extinguishing effect:

[0049] Change the gas fire extinguishing agent in the test example into 1,1,2,2,3,3,4-heptafluorocyclopentane, with the same equipment and operation steps of test example 1, measure the gas fire extinguishing agent of embodiment 4 Extinguishing concentration.

[0050]

[0051] It can be seen from the experimental results that when 90% of 1,1,2,2,3,3,4-heptafluorocyclopentane is mixed with 10% of BTP to extinguish the fire, the theoretical calculation value of the fire extinguishing concentration under the synergy is not considered It is 6.87%, while the experimentally measured fire extinguishing concentration is only 5.6%. This proves that the composite fire extinguishing medium formed by 1,1,2,2,3,3,4-heptafluorocyclopentane and BTP shows a good positive and synergistic fire extinguis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com