A preparation method of thin-strip solid wood composite integrated board

A solid wood composite and integrated board technology, applied in the direction of wood layer products, wood processing appliances, chemical instruments and methods, etc. Large combined area, high wood utilization rate, and the effect of improving the strength of the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

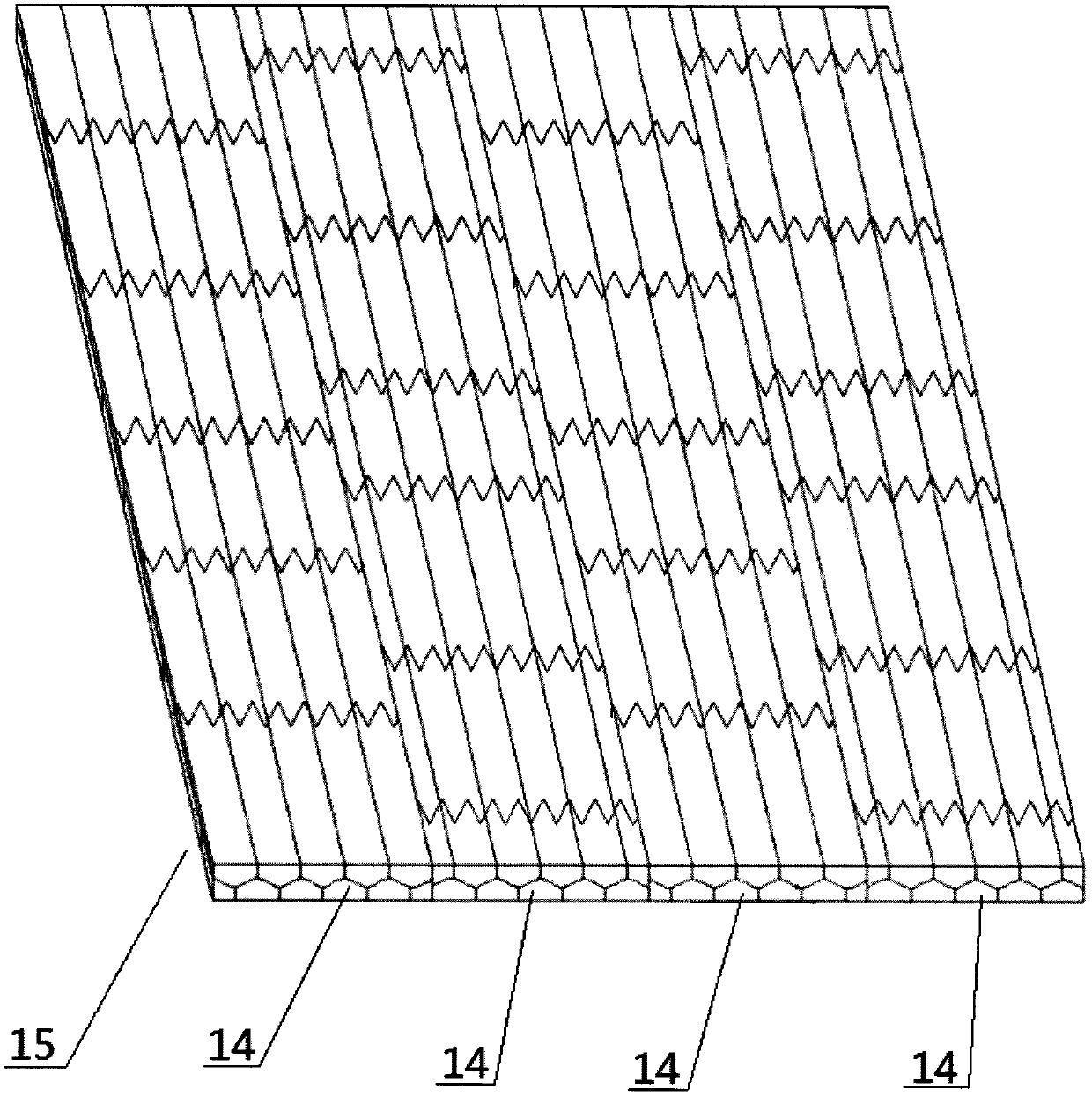

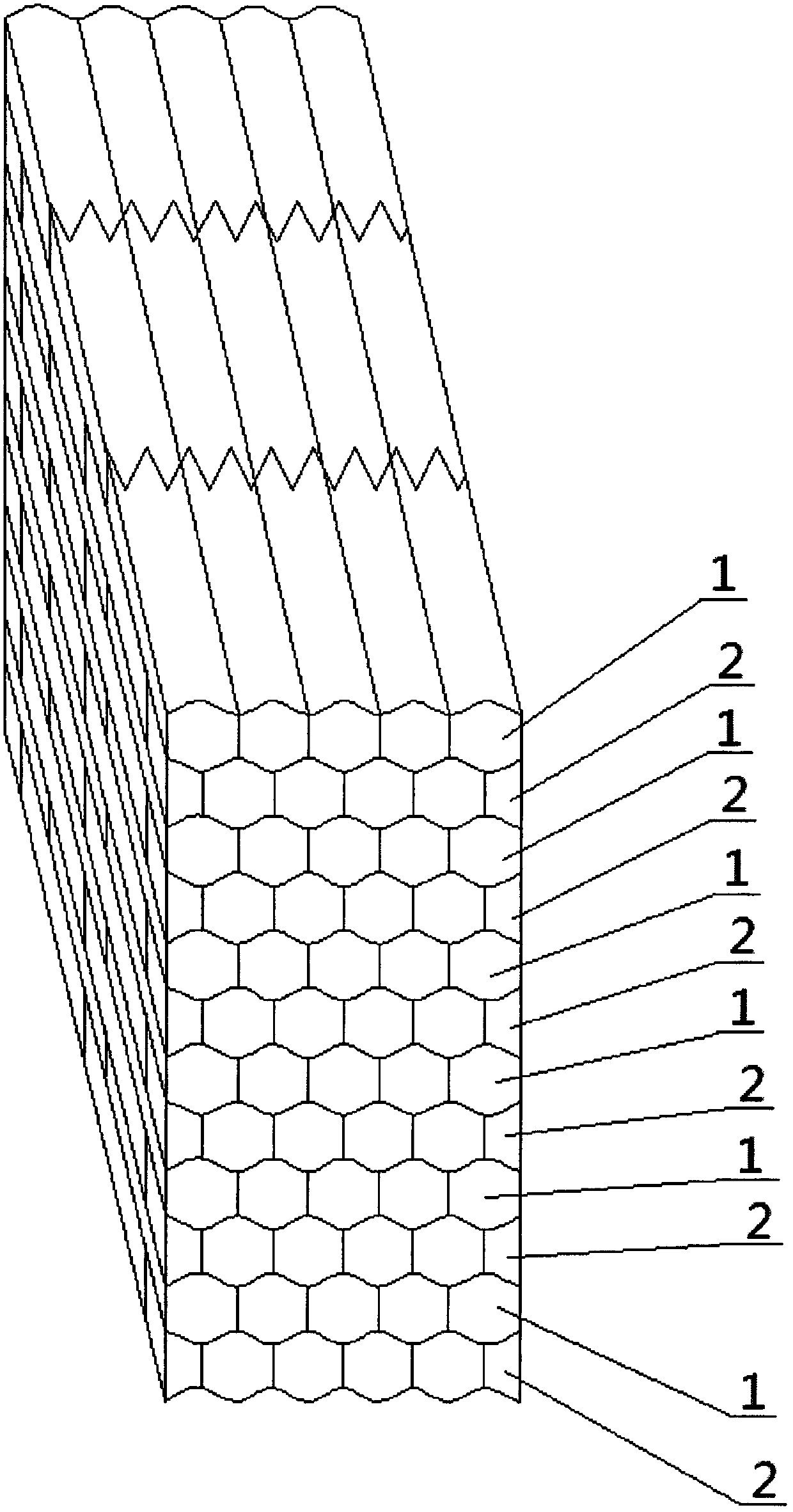

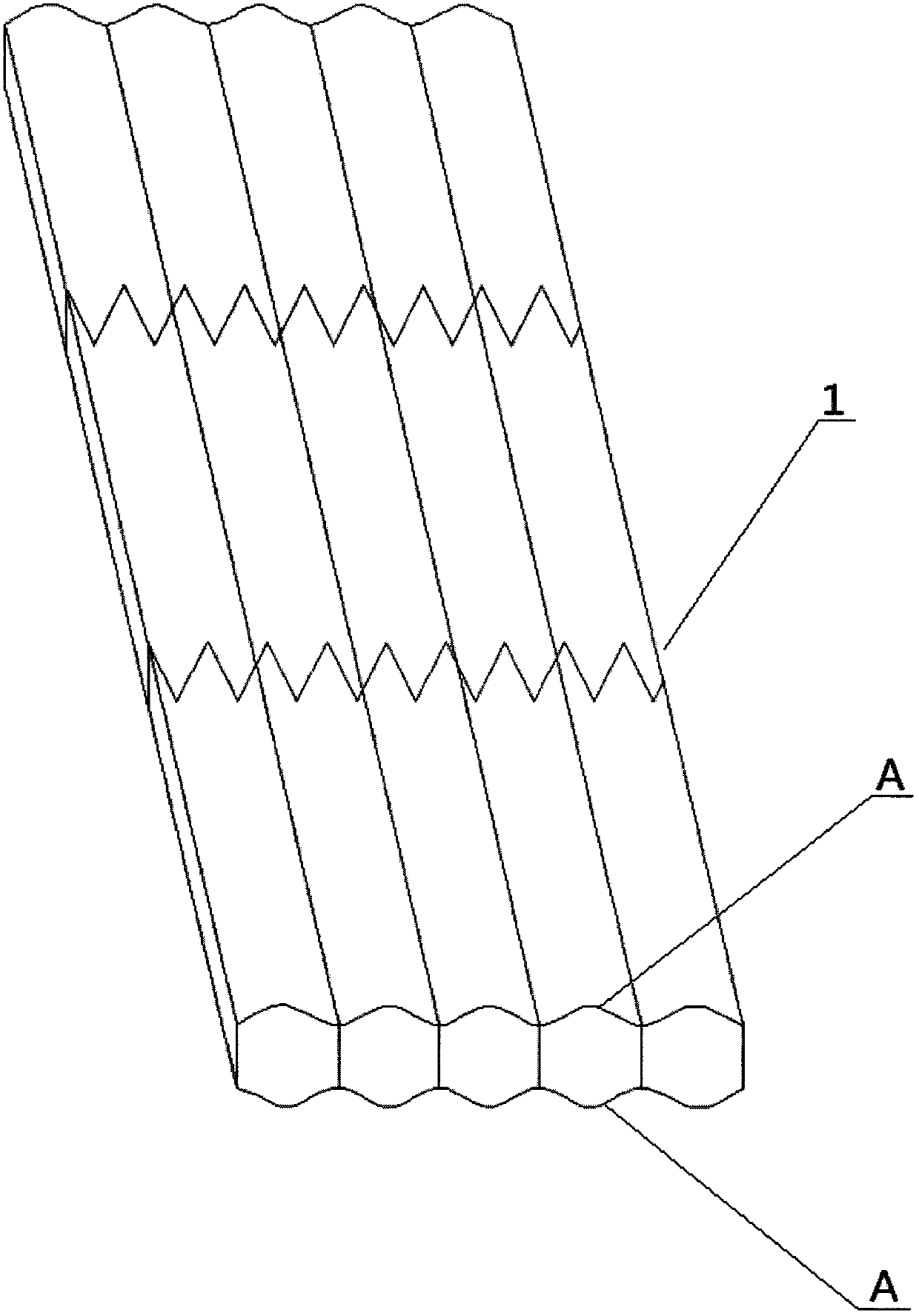

[0066] 1. Preparation of thin-strip composite integrated wood cubes:

[0067] The thin-strip composite integrated wood square is composed of composite board 1 and composite board 2;

[0068] The composite board 1 is processed from the composite board 3 3, and the composite board 3 3 is composed of 10 small square strips 4 with four-corner circular arcs, wherein the small square strips 4 with four-corner circular arcs It is processed from a thin strip (diameter 2-3CM) cylindrical wooden mandrel remaining from the production of veneer and plywood into an existing structure with four planes-5 and four-corner arcs-6; When the small square strips 14 are spliced to form the composite board 33, glue is evenly applied on the left and right planes 15 of the small square strips 14 with four-corner arcs, and then the above-mentioned small square strips 14 The left and right planes 1 and 5 correspond to each other and are spliced into composite boards 3 and 3. Then, carry out the lo...

Embodiment 2

[0076] 1. Preparation of thin-strip composite integrated wood cubes:

[0077] The thin-strip composite integrated wood square is composed of composite board 1 and composite board 2;

[0078]The composite board 1 is processed from the composite board 3 , and the composite board 3 3 is composed of 20 small square strips 4 with four-corner circular arcs, wherein the small square strips 4 with four-corner circular arcs It is processed from a thin strip (diameter 2-3CM) cylindrical wooden mandrel remaining from the production of veneer and plywood into an existing structure with four planes-5 and four-corner arcs-6; When the small square strips 14 are spliced to form the composite board 33, glue is evenly applied on the left and right planes 15 of the small square strips 14 with four-corner arcs, and then the above-mentioned small square strips 14 The left and right planes 1 and 5 correspond to each other and are spliced into composite boards 3 and 3. Then, carry out the long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com