Inorganic expanded fireproof coating and preparation method

A fire retardant coating, inorganic technology, applied in the direction of fire retardant coatings, coatings, etc., can solve the danger of personal injury, can not solve the problems of toxic and harmful smoke, safety hazards, etc., to achieve the effect of reducing the harm of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

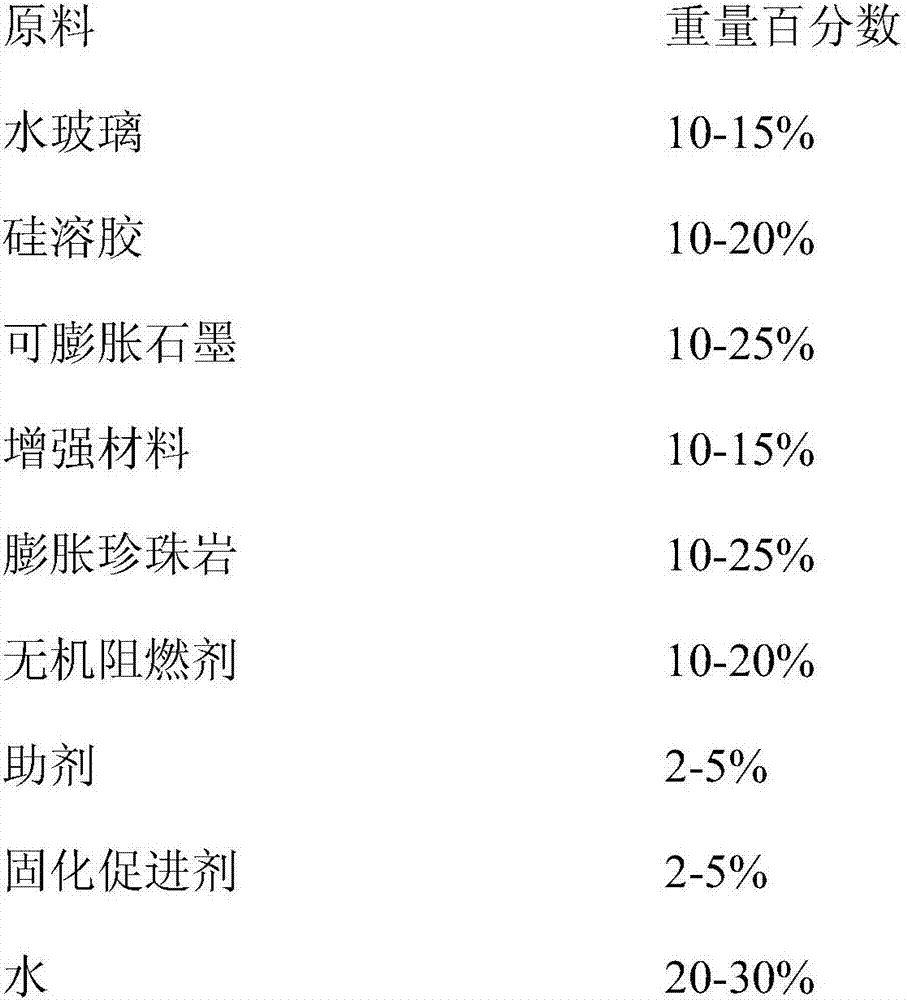

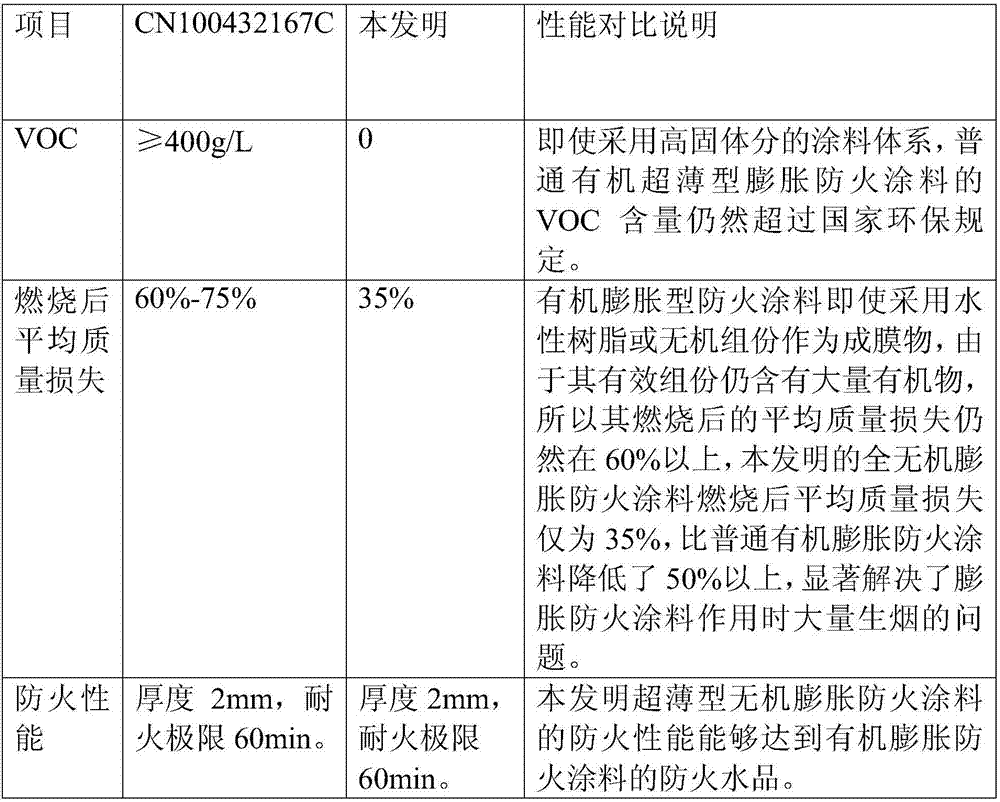

Method used

Image

Examples

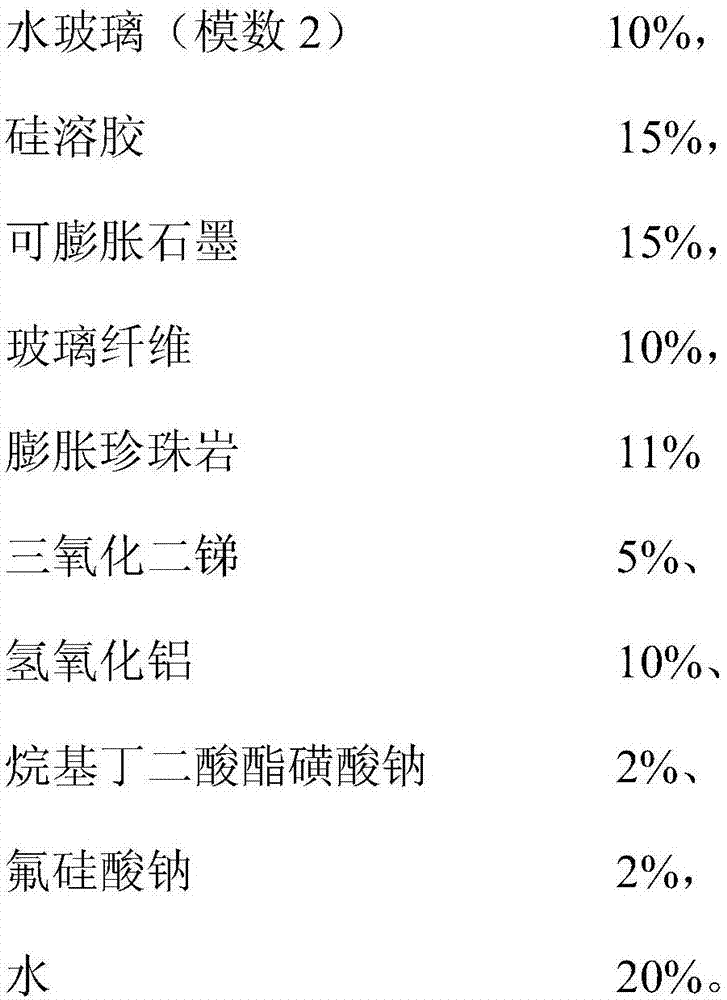

Embodiment 1

[0016]

[0017] Preparation and construction method:

[0018] (1) Add water glass, silica sol, glass fiber, antimony trioxide and aluminum hydroxide into water, and disperse evenly with a high-speed mixer at 3000r / min.

[0019] (2) Add expandable graphite, expanded perlite, and alkyl succinate sulfonate, and disperse evenly at 500r / min.

[0020] (3) Add 2% sodium fluorosilicate, stir evenly by hand, and evenly coat the surface of the substrate by trowel coating.

Embodiment 2

[0022] Water glass (modulus 2.5) 25%, expandable graphite 10%, aluminum silicate fiber 10%, expanded perlite 8%, antimony trioxide 8%, aluminum hydroxide 8%, magnesium hydroxide 7%, alkyl Sodium succinate sulfonate 2%, sodium fluorosilicate 2%, water 20%.

[0023] Preparation and construction method:

[0024] (1) Add water glass, aluminum silicate fiber, antimony trioxide, aluminum hydroxide, and magnesium hydroxide into water, and disperse evenly with a high-speed mixer at 3000r / min.

[0025] (2) Add expandable graphite, expanded perlite, and alkyl succinate sulfonate, and disperse evenly at 500r / min.

[0026] (3) Add 2% sodium fluorosilicate, stir evenly by hand, and evenly coat the surface of the substrate by trowel coating. Comparative example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com