Special anti-settling thickener for building paint and preparation method thereof

A technology of architectural coatings and thickeners, applied in coatings, etc., can solve problems such as easy pigment and filler deposition, poor suspension and anti-sedimentation, coating production, storage, construction, and film-forming effects, etc., to achieve thickening Good anti-sedimentation effect, strong thickening, excellent stability and suspension effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

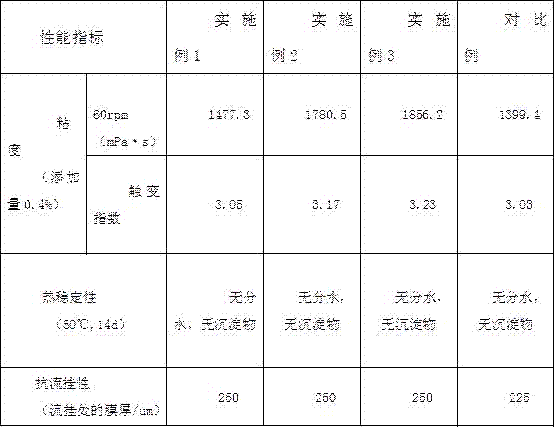

Examples

Embodiment 1

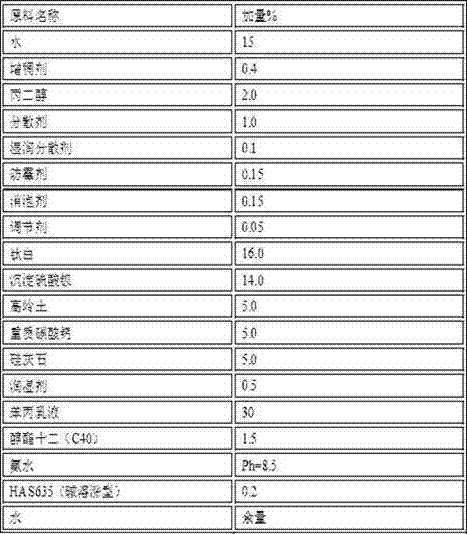

[0024] A special anti-settling thickener for architectural coatings, in parts by weight, comprising the following components:

[0025] 8 parts of polyethylene glycol,

[0026] 13 parts of isophorone diisocyanate,

[0027] 2 parts of nonylphenol polyoxyethylene ether,

[0028] 6 parts of anti-settling additives,

[0029] 30 parts of water;

[0030] The anti-sedimentation additives are mineral soil, glue thickener, cellulose thickener and water, the ratio is 0.1:0.1:0.1:100,

[0031] The preparation method of special anti-settling thickener for architectural coatings of the present invention comprises the following steps:

[0032] (1) Add polyethylene glycol and end-capping agent nonylphenol polyoxyethylene ether into a four-necked flask equipped with an electric mixer, start stirring at a low speed, and heat up to 120°C for vacuum drying and dehydration for 1 hour;

[0033] (2) Slowly pass nitrogen gas into the four-neck flask, cool down to 70°C, add isophorone diisocyanat...

Embodiment 2

[0037] A special anti-settling thickener for architectural coatings, in parts by weight, comprising the following components:

[0038] 12 parts of polyethylene glycol,

[0039] 16 parts of isophorone diisocyanate,

[0040] 4 parts of nonylphenol polyoxyethylene ether,

[0041] 10 parts of anti-settling additives,

[0042] 60 parts of water;

[0043] The anti-sedimentation additive is mineral soil, glue thickener, cellulose thickener and water, the ratio is 5:5:5:100,

[0044] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0046] A special anti-settling thickener for architectural coatings, in parts by weight, comprising the following components:

[0047] 10 parts of polyethylene glycol,

[0048] 14 parts of isophorone diisocyanate,

[0049] 3 parts of nonylphenol polyoxyethylene ether,

[0050] 8 parts of anti-settling additives,

[0051] 45 parts of water;

[0052] The anti-sedimentation additives are mineral soil, glue thickener, cellulose thickener and water, and the ratio is 2.5:2.5:2.5:100.

[0053] The preparation method of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com