New technology for conducting grouting filling for underground coal goaf and abandoned workings

A kind of goaf and new technology, which is applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve the problems of wasting time, difficult to realize the micro-pressure grouting process, and unable to realize the non-pressure grouting process with large flow rate, etc. , to achieve the effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

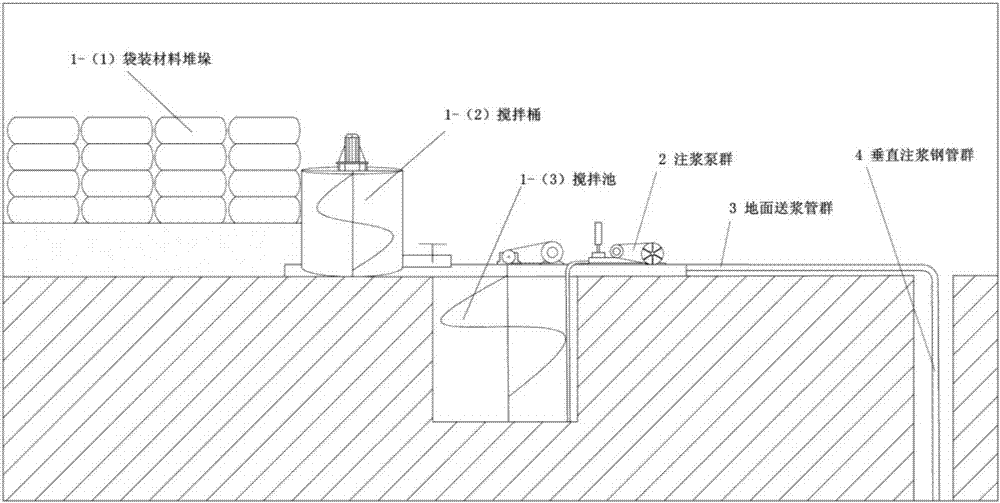

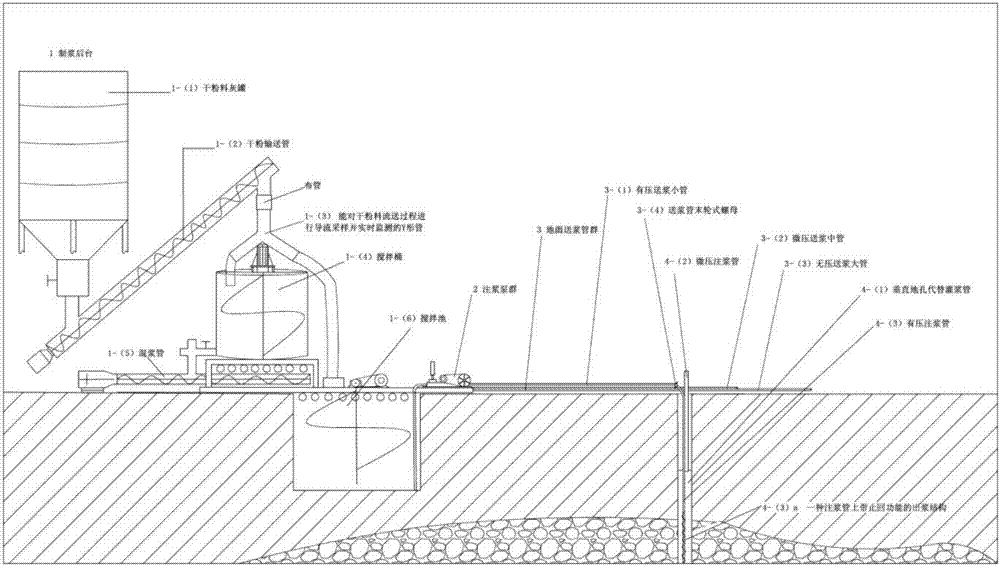

[0016] The construction steps of the new technology of grouting and grouting filling for underground coal mined-out areas and waste roadways of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] Step 1: Pilot hole: use geological drilling rig or down-the-hole drilling rig to drill holes from the ground to the ground, directly or through the coal seam goaf or waste roadway in the deep stratum and other related cavities, gaps, cracks, etc.

[0018] The second step: grouting and non-pressure grouting:

[0019] (1) Pulping: The grouting slurry consists of a dry powder ash tank, a dry powder delivery pipe, a Y-shaped tube that can conduct diversion sampling and real-time monitoring of the dry powder flow process, a slurry mixing pipe, a mixing bucket, and a mixing tank. The pool and other components form a new technology for pulping and mixing in the background. One is that the pulping background c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com