Hot-rolled H-shaped steel with good low-temperature ductility at minus 60 DEG C and production method thereof

A technology of low temperature toughness and production method, which is applied in the field of metal material production to achieve the effect of reducing costs, reducing post-weld visual inspection and welding seam inspection processes, and reducing welding processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A hot-rolled H-shaped steel with good low-temperature toughness at -60°C, containing the following elements by weight: 0.10% carbon, 0.28% silicon, 1.41% manganese, 0.010% phosphorus, 0.008% sulfur, 0.045% vanadium, and 0.025% niobium , Nickel 0.15%, Als 0.020%.

[0023] The production process is controlled as follows: the heating temperature is controlled at 1220-1240°C, the starting rolling temperature is controlled at 1120°C, the opening rolling temperature of the universal rolling pass is controlled at 940°C, and the final rolling temperature is controlled at 860°C; The cooling rate is controlled at 52%; cooling process control: the rolled piece is cooled at a rate of 65°C / s to a phase transformation around 640°C, returned to 680°C, and then naturally cooled to room temperature.

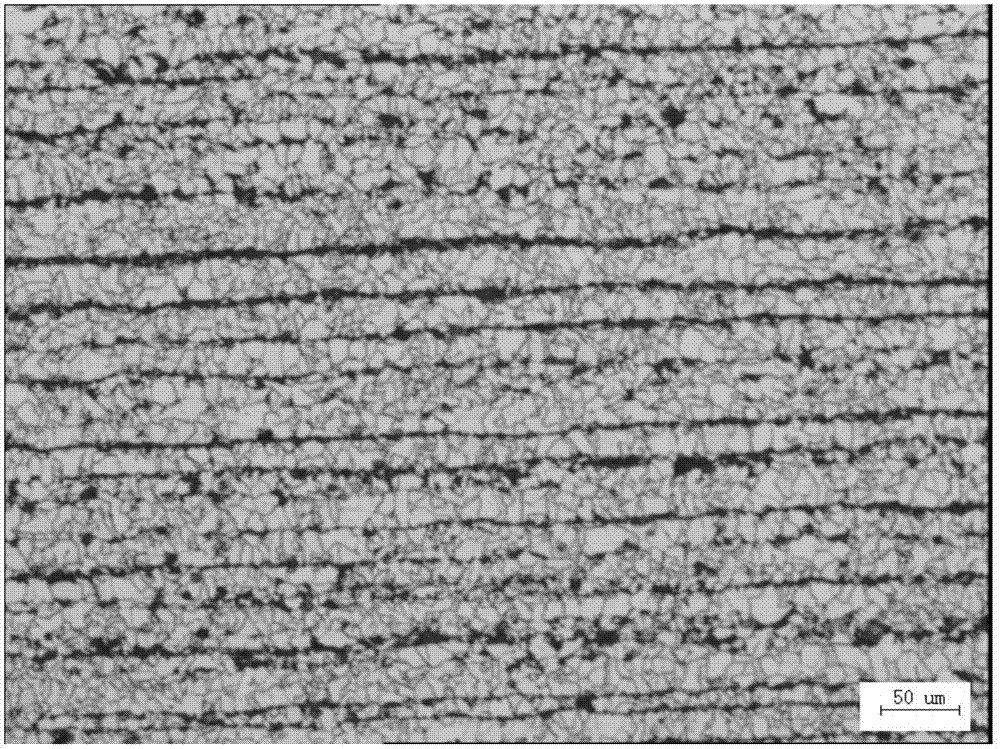

[0024] The hot-rolled H-shaped steel of 428 × 407 × 20 × 35 specifications produced by the process of the present invention, the grain size of 100x is as image 3 As shown; its tensile st...

Embodiment 2

[0026] A hot-rolled H-shaped steel with good low-temperature toughness at -60°C, containing the following elements by weight: 0.10% carbon, 0.25% silicon, 1.35% manganese, 0.007% phosphorus, 0.005% sulfur, 0.036% vanadium, and 0.020% niobium , Nickel 0.13%, Als 0.022%.

[0027] The production process is controlled as follows: the heating temperature is controlled at 1220-1240°C, the starting rolling temperature is controlled at 1100°C, the opening rolling temperature of the universal rolling pass is controlled at 925°C, and the final rolling temperature is controlled at 842°C; The cooling rate is controlled at 55%; the cooling process control: the rolled piece is cooled at a rate of 57 °C / s to a phase change near 600 °C, returned to 658 °C, and then naturally cooled to room temperature.

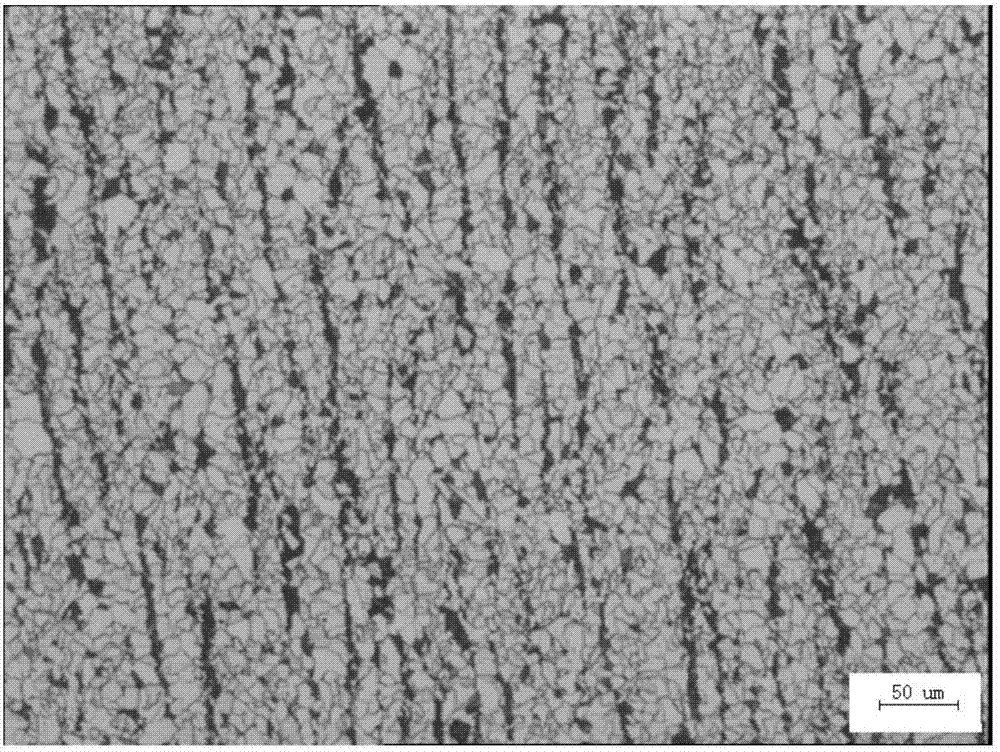

[0028] The hot-rolled H-shaped steel of 400 * 400 * 13 * 21 specifications produced by the process of the present invention, the grain size of 100x is as figure 2 As shown; its tensile stre...

Embodiment 3

[0030] A hot-rolled H-shaped steel with good low-temperature toughness at -60°C, containing the following elements by weight: 0.10% carbon, 0.28% silicon, 1.41% manganese, 0.010% phosphorus, 0.008% sulfur, 0.045% vanadium, and 0.025% niobium , Nickel 0.15%, Als 0.020%.

[0031] The production process is controlled as follows: the heating temperature is controlled at 1220-1240°C, the starting rolling temperature is controlled at 1120°C, the opening rolling temperature of the universal rolling pass is controlled at 940°C, and the final rolling temperature is controlled at 860°C; The cooling rate is controlled at 52%; cooling process control: the rolled piece is cooled at a rate of 65 °C / s to a phase transformation around 640 °C, returned to 680 °C, and then naturally cooled to room temperature.

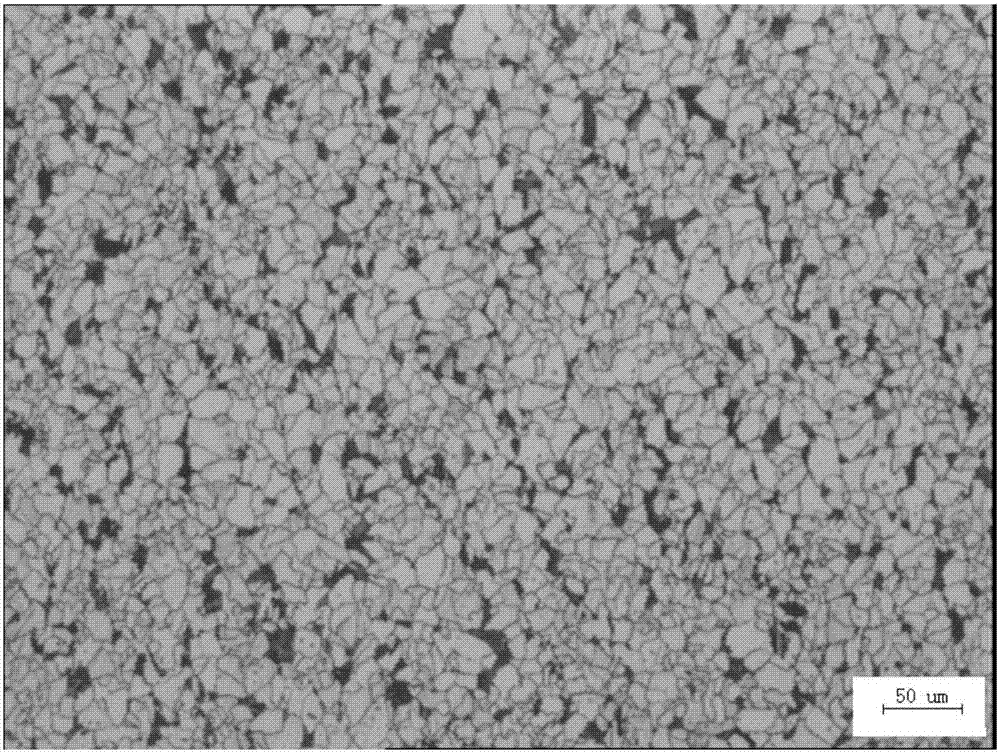

[0032] The hot-rolled H-shaped steel of 194 * 150 * 6 * 9 specifications produced by the process of the present invention, 100x grain size such as figure 1 As shown; its tensile streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com