Automatic mixing and dispensing machine for roadbed lime-clay

A lime-soil, automatic technology, applied in the field of civil engineering, can solve the problems of difficulty in controlling the proportion of lime-soil components, uncontrollable lime-soil humidity, and needing too much equipment, etc., to achieve the effect of perfect deployment function, reduce labor workload, and improve project quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

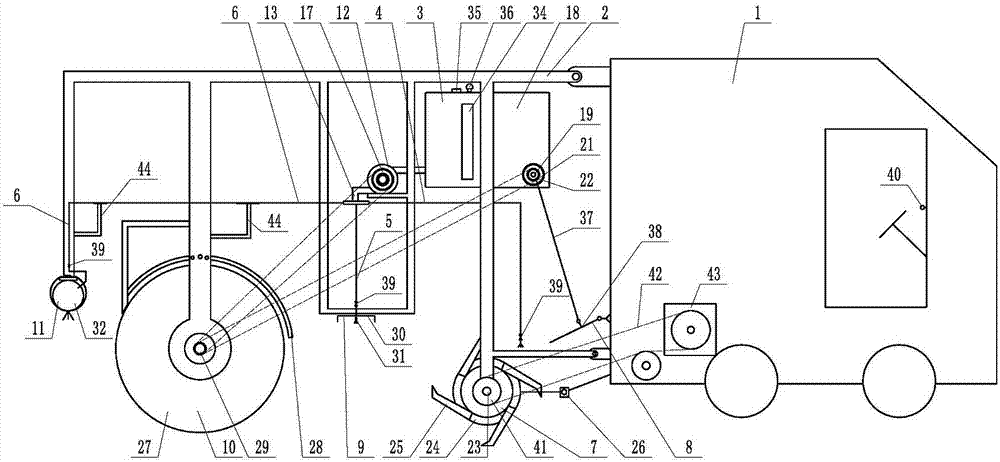

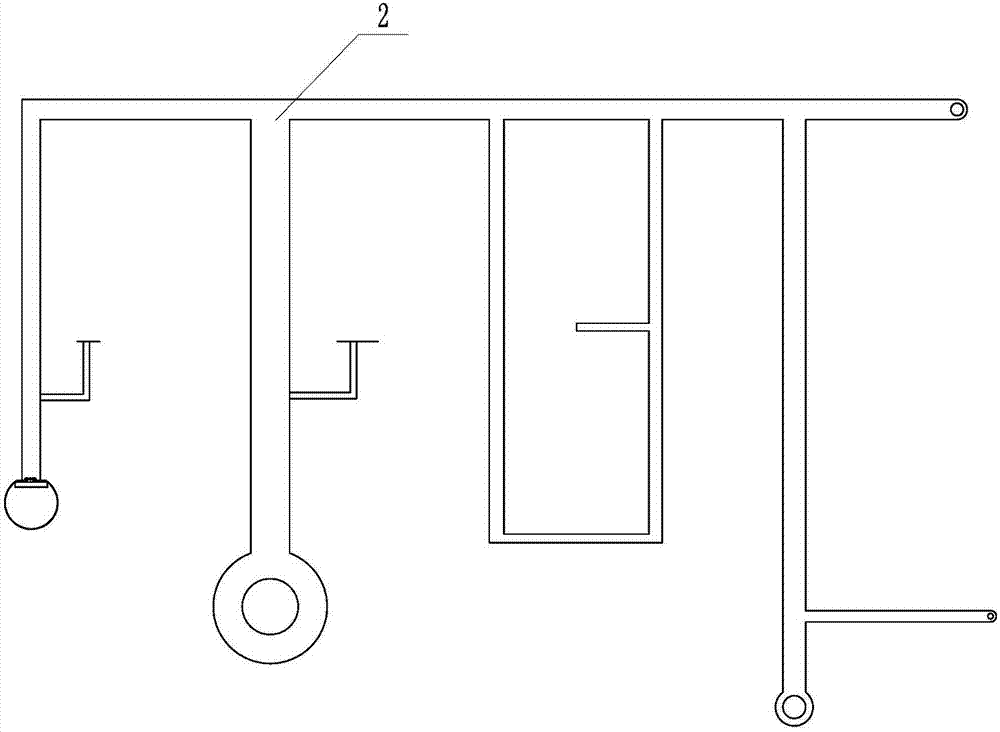

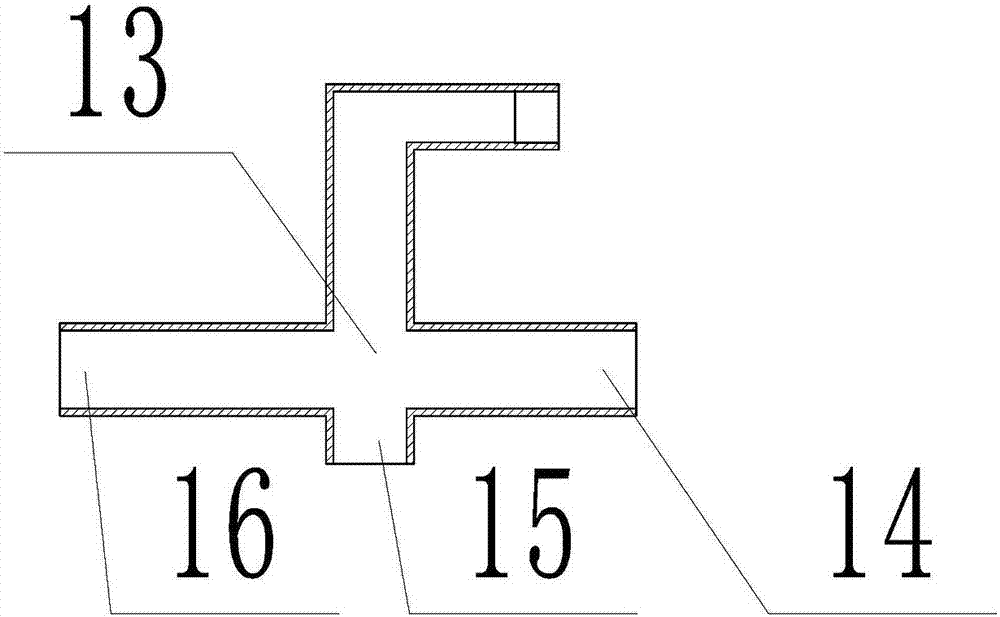

[0039] Embodiment 1. The present invention is an automatic mixing and spreading machine for roadbed lime soil, which includes a tractor. A frame 2 is installed on the tractor 1. The frame 2 is hingedly connected with the tractor 1. There are two fixed A water tank 3 is installed on one of the fixed positions, and three water pipes are installed below the water tank 3, which are respectively the first water pipe 4, the second water pipe 5 and the third water pipe 6, and there is a mixing device 7 below the first water pipe 4. The mixing device 7 is installed on the frame 2, the right side of the mixing device 7 is provided with a buffer device 8, the left side of the mixing device 7 is equipped with a humidifying device 9, and the humidifying device 9 is fixed on the frame 2 by a plurality of bolts. On the left side of 9, there is a rolling device 10, which is fixed on the frame 2, and on the left side of the rolling device 10, there is a dust prevention device 11 installed on t...

Embodiment 2

[0045] Embodiment two, on the basis of embodiment one, observation window 34 is arranged on described water tank 3, liquid level switch 35 is installed in water tank 3, is connected with alarm bell 36 on liquid level switch 35, and alarm bell 36 is installed in water tank outside.

Embodiment 3

[0046] Embodiment 3, on the basis of Embodiment 1, the buffer device 8 includes a connecting rod 37, the upper end of the connecting rod 37 is hinged with the pin 22, and the lower end of the connecting rod 37 is equipped with a buffer plate 38, which bears the falling slaked lime powder, and then rhythmically send the slaked lime powder to the mixing device 7 to reduce dust. The left side of the buffer plate 38 is hinged with the tractor 1, and the buffer plate 38 is hinged with the connecting rod 37. The length of the buffer plate 38 is greater than the horizontal axis 23 The length of the buffer plate 23 does not interfere with the mixing device 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com