Test device and method for sliding friction force of biological soft tissue material

A technology of biological soft tissue and sliding friction, which is applied in the direction of measuring devices, analyzing materials, and adopting mechanical devices, can solve problems such as difficult friction, non-uniformity, and complexity, and achieve high precision, cost saving, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

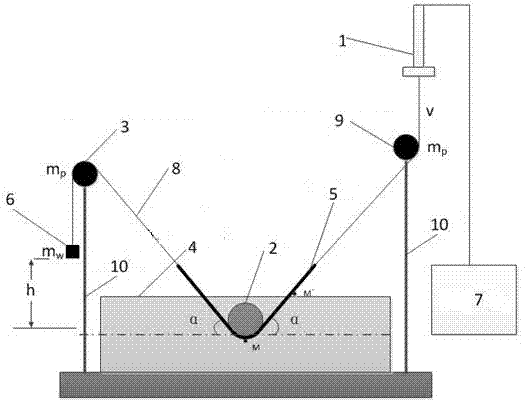

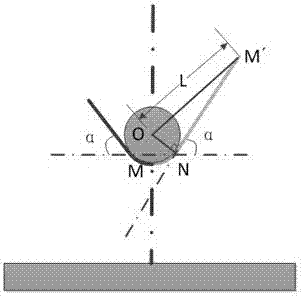

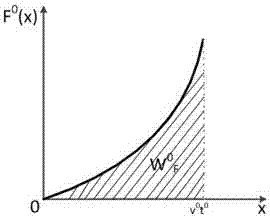

[0064] (1) Wrap the test piece made of cartilage on the fixed rod, and adjust the first and second fixed pulleys so that the tension line forms an angle of 45° with the horizontal direction. The mass of the weight is 1.00kg, the mass of the test piece is 0.25kg, the original length is 0.30m, the mass of the fixed pulley is 0.50kg, the radius of the fixed pulley is 0.02m, and the radius of the fixed rod is 0.02m. And mark M point on the test soft tissue (point directly below the center of the fixed rod), then start the tensile testing machine, set the speed v=0.0010m / s, and the time is 120s, record the height of the weight rise, and measure the red fixed rod The distance l from the center point O to the point M′, with no load once, record the rising height h of the weight 0 . Repeat the experiment 5 times, increase the speed of each experiment by 0.0005m / s, and record the data in the following table:

[0065] Table 1: Example 1——Test data form of friction force between cartil...

Embodiment 2

[0072] (1) Wrap the test piece made of skin on the fixed rod, and adjust the first and second fixed pulleys so that the tension line forms an angle of 60° with the horizontal direction. The mass of the weight is 1.00kg, the mass of the test piece is 0.20kg, the original length is 0.40m, the mass of the fixed pulley is 1.00kg, the radius of the fixed pulley is 0.03m, and the radius of the fixed rod is 0.03m. And mark M point on the test soft tissue (point directly below the center of the fixed rod), then start the tensile testing machine, set the speed v=0.0020m / s, and the time is 90s, record the height of the weight rise, and measure the red fixed rod The distance l from the center point O to the point M′, with no load once, record the rising height h of the weight 0 . Repeat the experiment 5 times, increase the speed of each experiment by 0.0004m / s, and record the data in the following table:

[0073] Table 2: Example 2—the test data form of friction force between skin tiss...

Embodiment 3

[0080] (2) Wrap the specimen made of Achilles tendon on the fixed rod, and adjust the first and second fixed pulleys so that the tension line forms an angle of 30° with the horizontal direction. The mass of the weight is 0.50kg, the mass of the test piece is 0.25kg, the original length is 0.10m, the mass of the fixed pulley is 0.50kg, the radius of the fixed pulley is 0.02m, and the radius of the fixed rod is 0.02m. And mark the point M on the test soft tissue (the point directly below the center of the fixed rod), then start the tensile testing machine, set the speed v=0.0010m / s, and the time is 200s, record the height of the weight rise, and measure the red fixed rod The distance l from the center point O to the point M′, with no load once, record the rising height h of the weight 0 . Repeat the experiment 5 times, increase the speed of each experiment by 0.0005m / s, and record the data in the following table:

[0081] Table 1: Example 1—the test data form of the friction f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com