Casting Defect Recognition Method Based on Human Vision Attention Mechanism

An attention mechanism and casting defect technology, applied in image analysis, image enhancement, instruments, etc., can solve the problems of complex calculation, poor adaptability, and low efficiency, and achieve high detection efficiency, high accuracy, and good recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

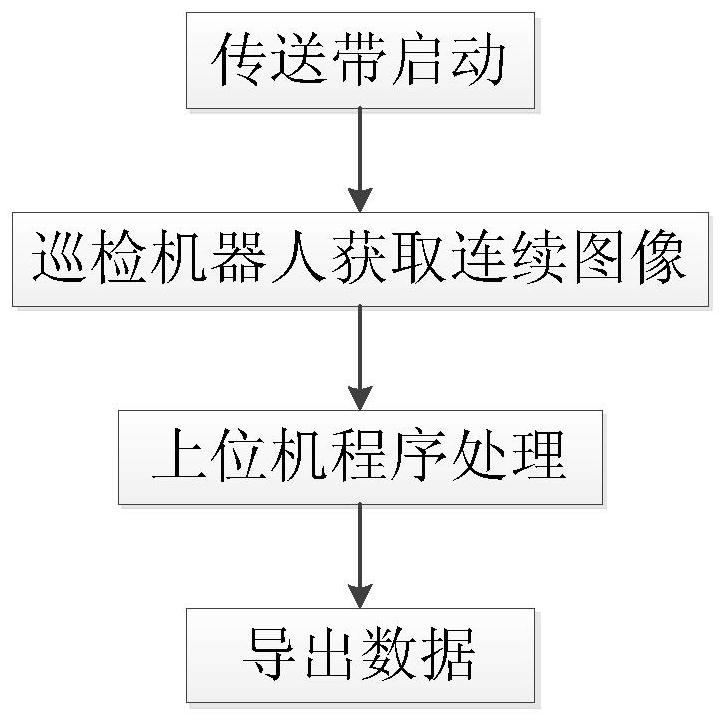

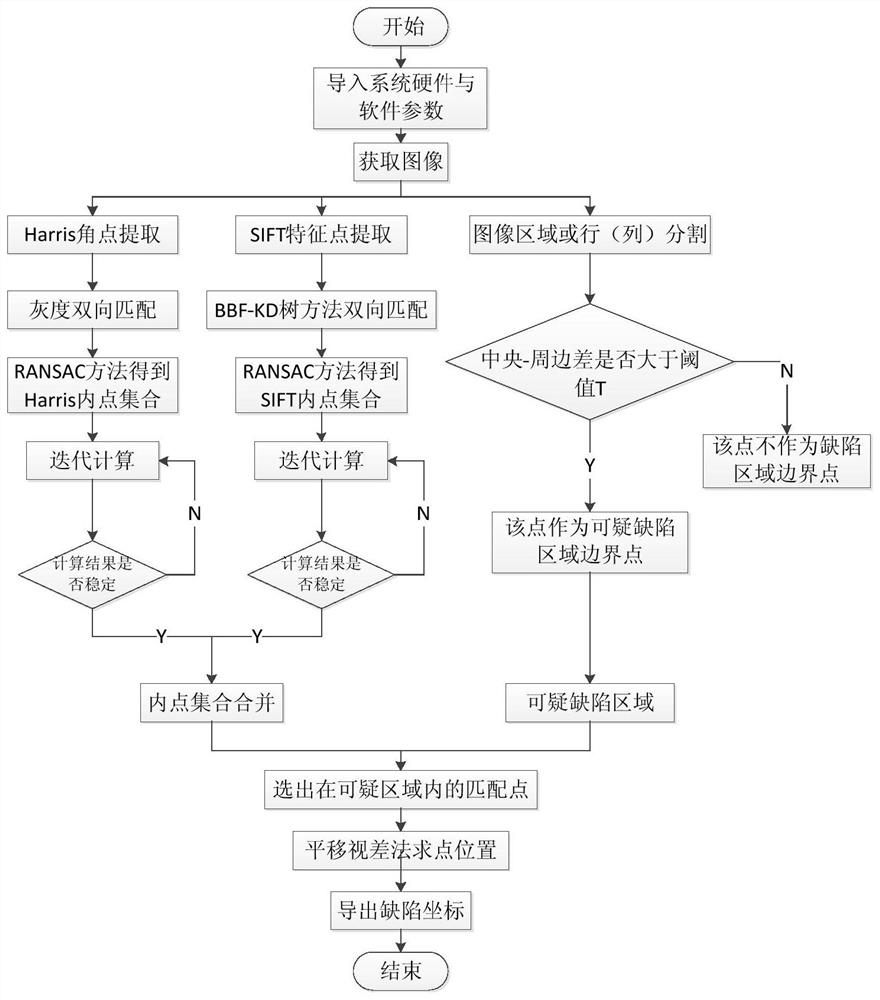

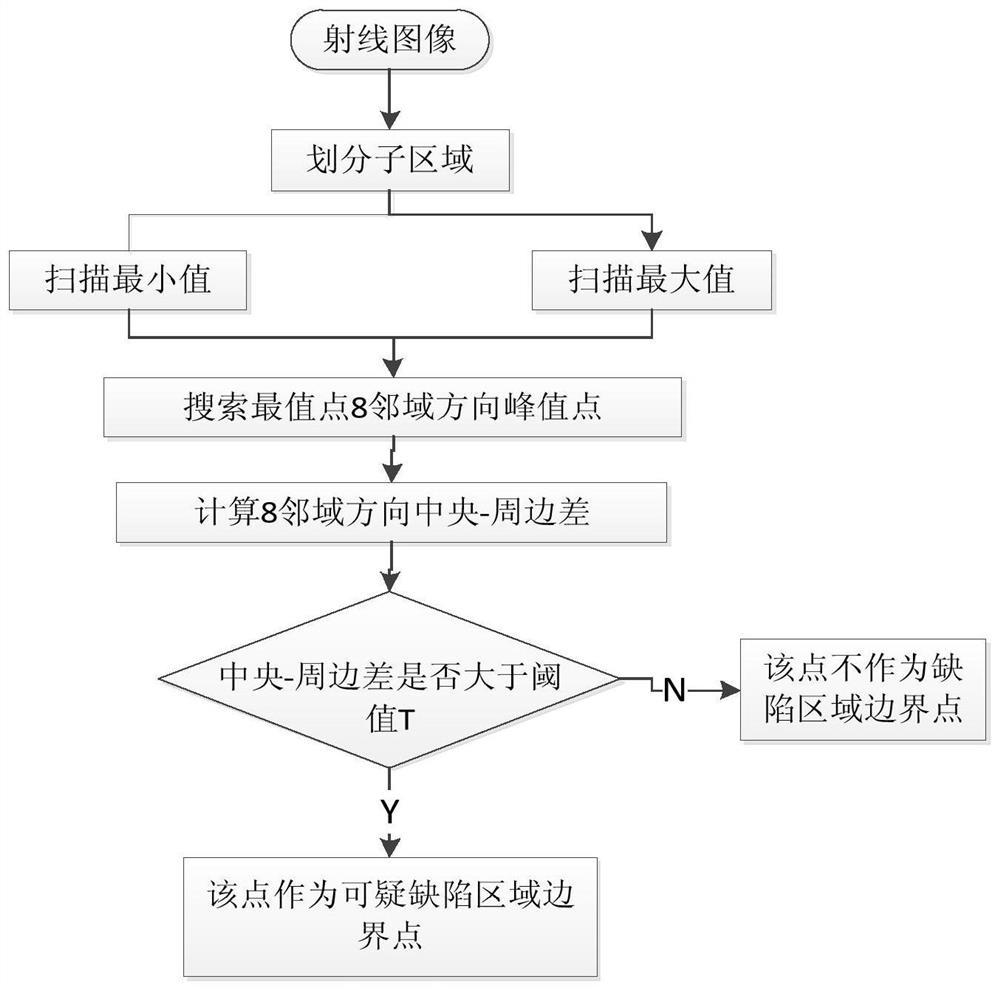

[0056] see figure 1 , the invention discloses a casting defect detection system based on the human eye vision mechanism, the system includes a patrol robot and a host computer, the patrol robot is used to obtain continuous casting radiographic images, that is, a dynamic sequence of casting radiographic images, and Upload the obtained continuous casting radiographic images to the upper computer, and the upper computer is used to collect the continuous casting radiographic images uploaded by the inspection robot, and perform image segmentation, defect matching, and defect location processing on the casting radiographic images to output positioning data .

[0057] The inspection robot randomly or fixedly acquires images of moving workpieces near the conveyor belt, and then the working process of the system is: (1) The system starts, the transmission belt starts to work, the feeder puts the castings on the conveyor belt, and the conveyor belt moves quickly; (2) The inspection rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com