Activation method for improving stability of gallium arsenide photocathode

A photocathode and stability technology, which is applied in the manufacture of light-emitting cathodes, can solve the unsatisfactory stability of GaAs photocathode and other problems, and achieve the effect of good activation method, easy promotion, and few operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

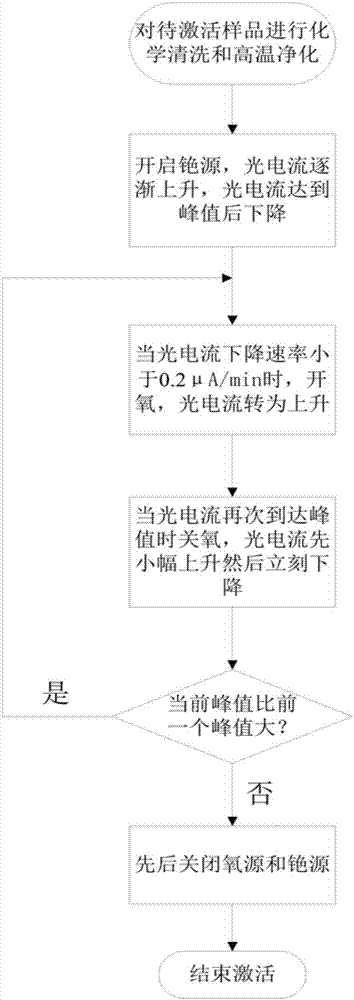

[0032] The activation process is as follows figure 1 shown.

[0033] Before cesium oxygen activation, we chemically clean and high-temperature purify the GaAs photocathode material.

[0034] The step of chemical cleaning is to first use H with a ratio of 4:1:100 2 SO 4 :H 2 o 2 :H 2 O mixed solution was chemically etched for 1 minute, and then put into HCl:H with a ratio of 1:1 2 O mixed solution was etched for 2 minutes, and finally the sample was repeatedly rinsed with deionized water and dried.

[0035] The step of high temperature purification is to send the sample to a vacuum degree not lower than 10 -7 In the ultra-high vacuum system of the order of Pa, the heating temperature is 650°C and the heating time is 20 minutes. After the sample is naturally cooled to room temperature, the sample is sent to the activation position, and the cesium oxygen activation starts.

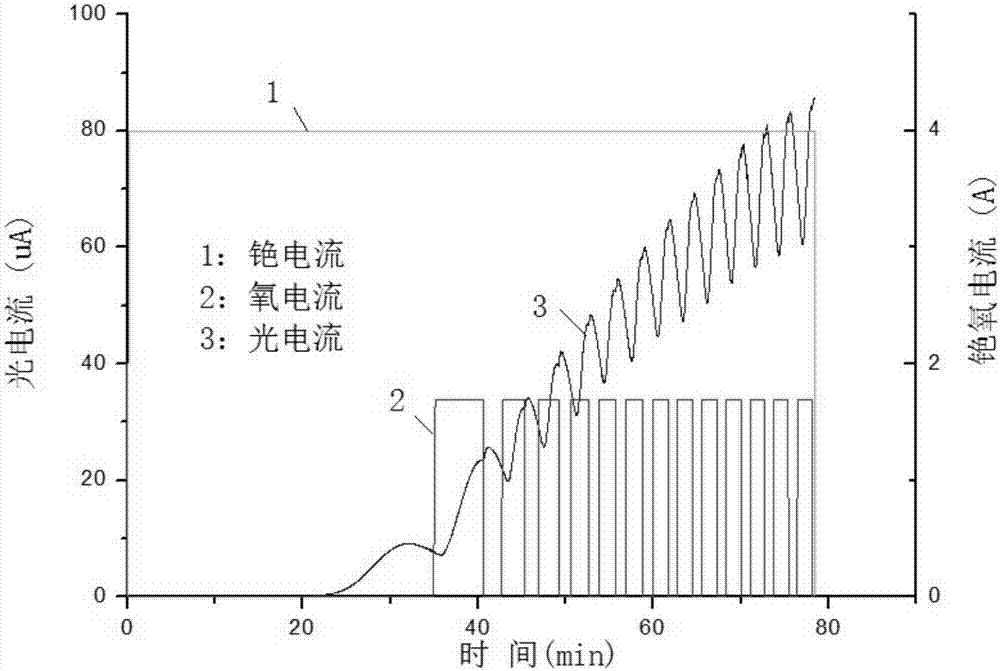

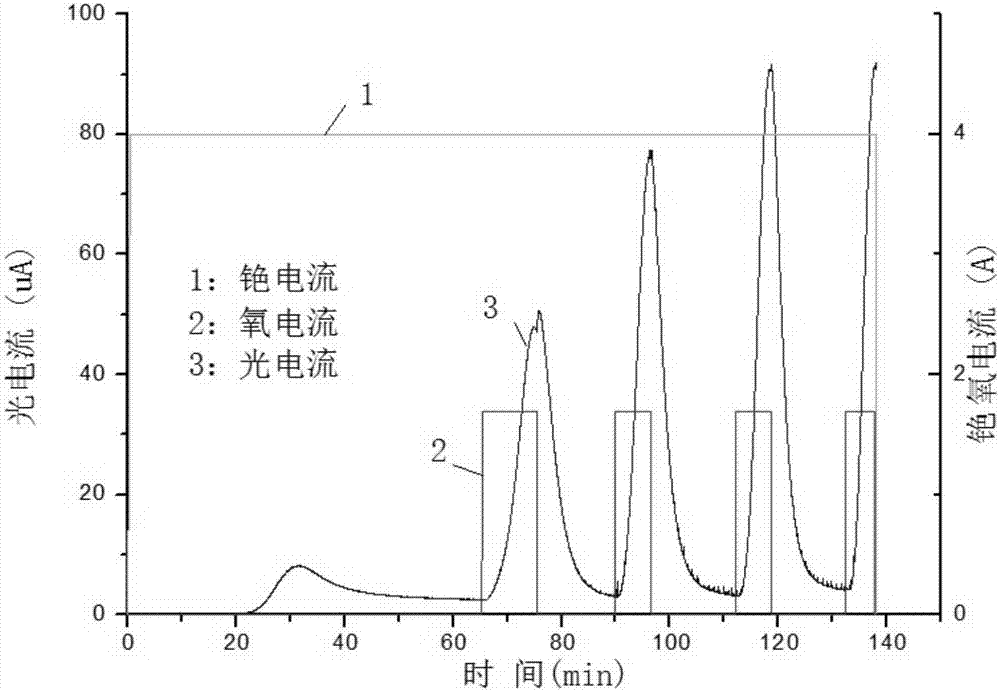

[0036] When activated, a tungsten-halogen lamp is used to irradiate the cathode surface verticall...

Embodiment 2

[0043] An activation method for improving the stability of gallium arsenide photocathode, comprising cesium source activation and oxygen source activation, the specific steps are as follows:

[0044] Step 1. Perform chemical cleaning and high-temperature purification on the sample to be activated;

[0045] The chemical cleaning method is as follows: first use H with a ratio of 4:1:100 2 SO 4 :H 2 o 2 :H 2 O mixed solution for chemical etching; then put in HCl:H with a ratio of 1:1 2 O mixed solution was etched, and finally the sample was rinsed with deionized water for at least one minute.

[0046] The high-temperature purification step is: put the sample after chemical cleaning into the ultra-high vacuum system for 30 minutes of heating, the heating temperature is 550°C, and the vacuum degree of the ultra-high vacuum system is not lower than 10 -7 Pa order of magnitude.

[0047] Step 2. Turn on the cesium source, the photocurrent gradually increases, and the photocurre...

Embodiment 3

[0054] An activation method for improving the stability of gallium arsenide photocathode, comprising cesium source activation and oxygen source activation, the specific steps are as follows:

[0055] Step 1. Perform chemical cleaning and high-temperature purification on the sample to be activated;

[0056] The chemical cleaning method is as follows: first use H with a ratio of 4:1:100 2 SO 4 :H 2 o 2 :H 2 O mixed solution for chemical etching; then put in HCl:H with a ratio of 1:1 2 O mixed solution was etched, and finally the sample was rinsed with deionized water for at least one minute.

[0057] The high-temperature purification step is: put the sample after chemical cleaning into the ultra-high vacuum system for 10 minutes of heating, the heating temperature is 650°C, and the vacuum degree of the ultra-high vacuum system is not lower than 10 -7 Pa order of magnitude.

[0058] Step 2. Turn on the cesium source, the photocurrent gradually increases, and the photocurre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com