Laser-assisted heating femtosecond pulse laser drilling device and method

A femtosecond pulse and laser drilling technology, used in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of slow processing speed of femtosecond pulse laser drilling, improve cutting efficiency and reduce ablation threshold. , The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

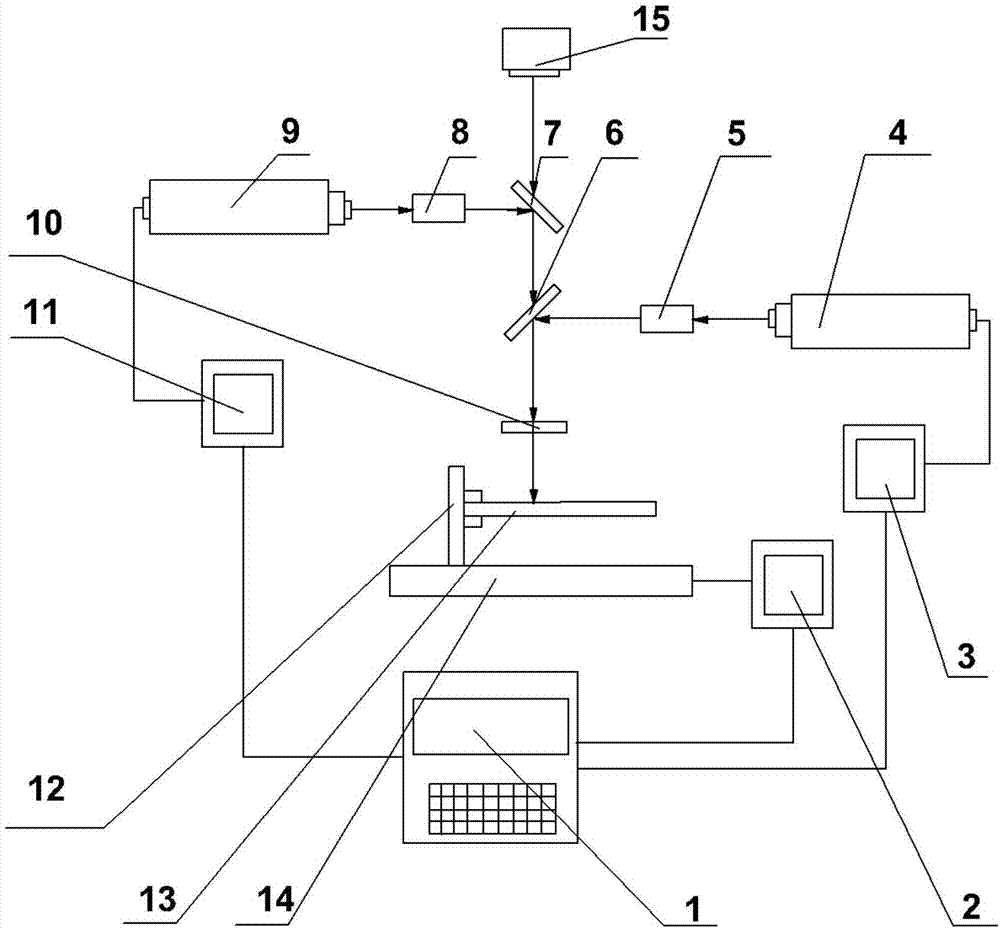

[0027] A laser-assisted heating femtosecond pulse laser drilling device, such as figure 1 As shown, it includes a computer 1, a workbench controller 2, a continuous laser controller 3, a continuous laser 4, a second beam expander 5, a beam splitter 6, a reflective flat mirror 7, a first beam expander 8, and a femtosecond pulse laser 9. Convex lens 10, femtosecond pulse laser controller 11, fixture 12, workpiece 13, movable worktable 14, and CCD camera 15.

[0028] The CCD camera 15 is located at the top, and directly below it is a reflective plane mirror 7, a beam splitter mirror 6 and a convex lens 10; the femtosecond pulse laser controller 11 is connected with the femtosecond pulse laser 9, and the continuous laser controller 3 is connected with the continuous laser 4. The workbench controller 2 is connected with the movable workbench 14; the femtosecond pulse laser controller 11, the continuous laser controller 3 and the workbench controller 14 are connected with the comput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com