A kind of ultrasonic vibration cutting working head

A technology of ultrasonic vibration and working head, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of non-waterproof and high temperature resistance, and achieve the effect of large working space, good surface quality and wide processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

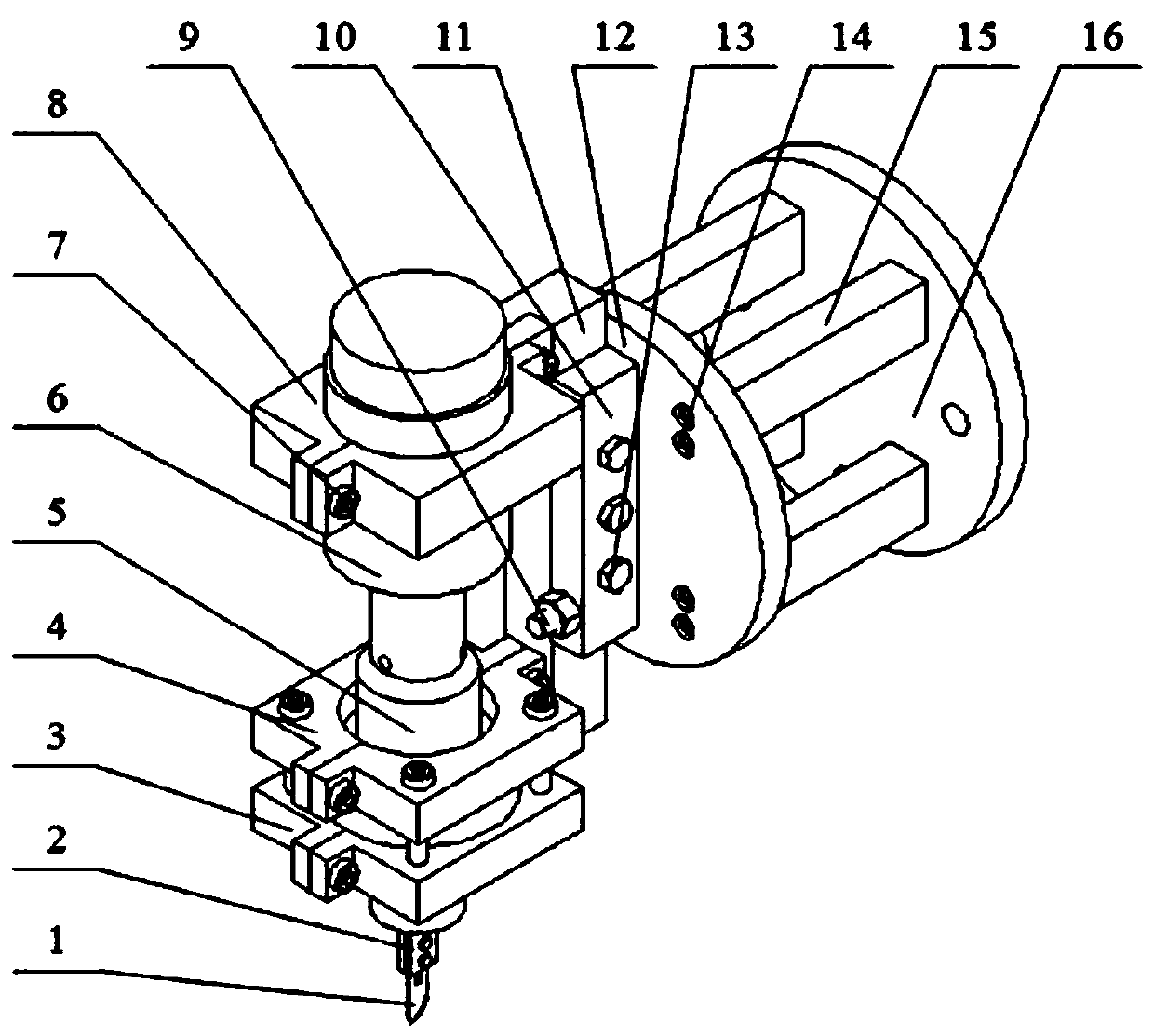

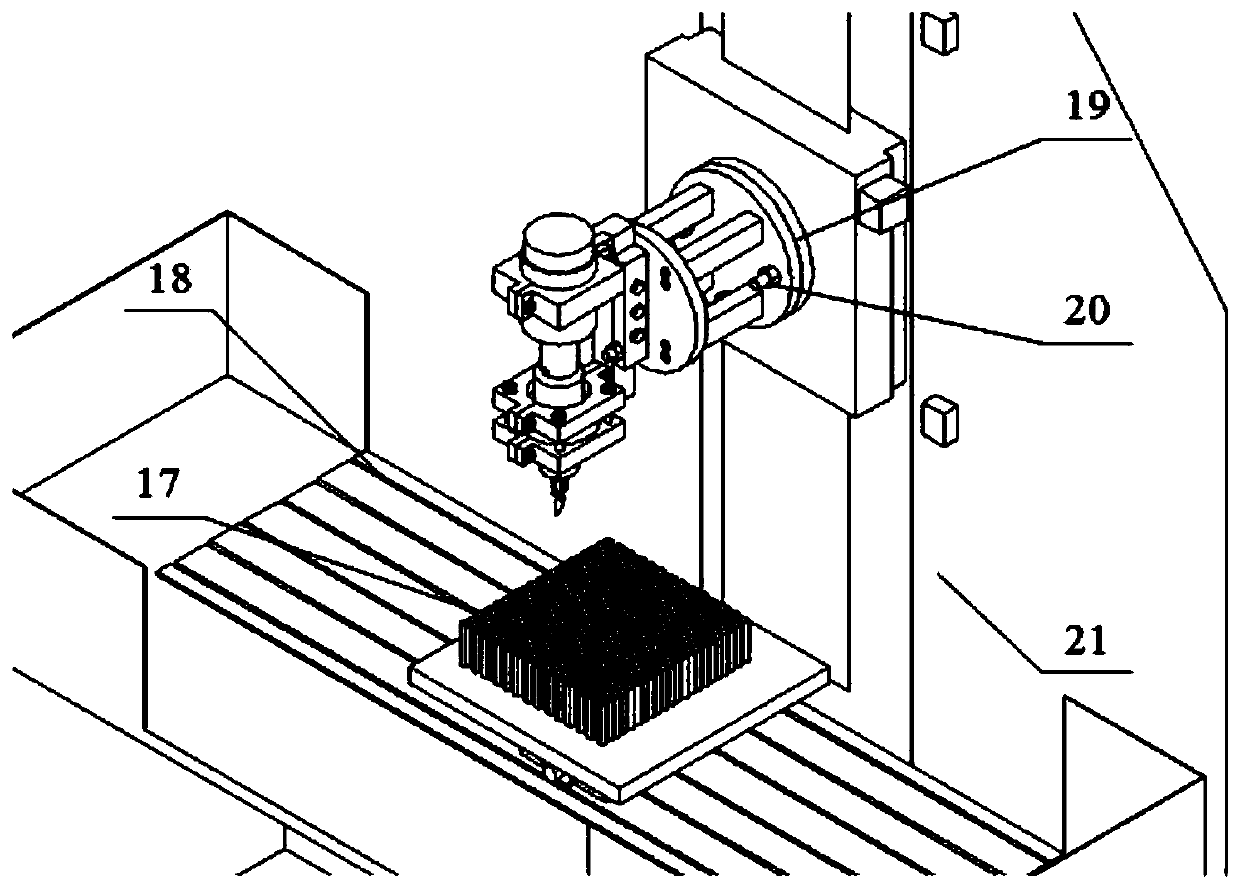

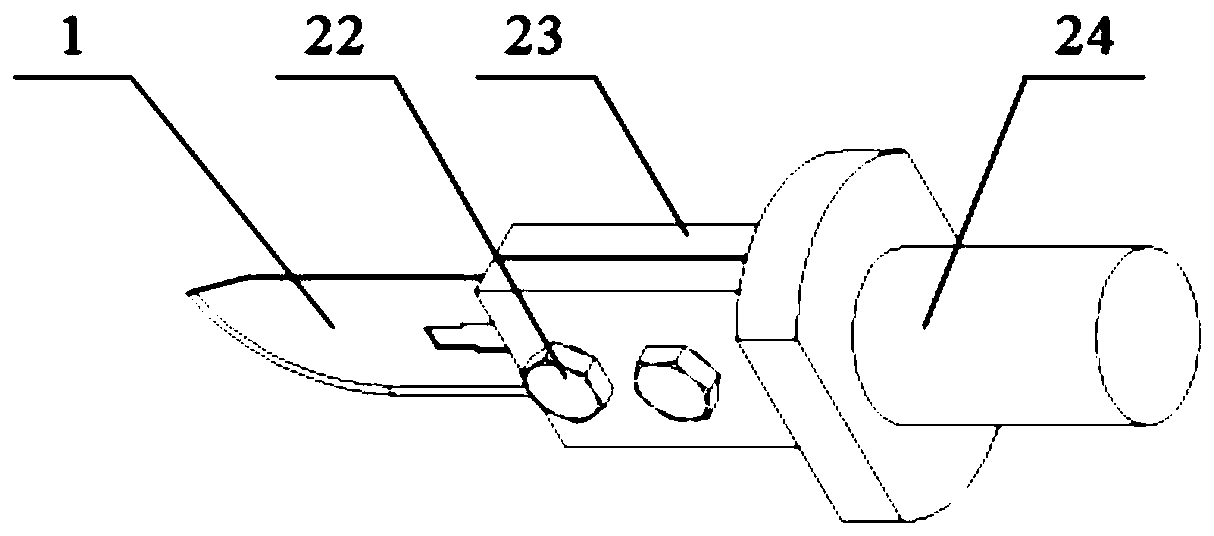

[0030] Such as Figure 1 to Figure 5 As shown, the blade 1 is connected to the horn 5 through the blade fixture 2, and the blade fixture 2 is connected to the horn 5 through a threaded connection. It achieves reliable fixation. During the ultrasonic vibration cutting process, by adjusting the angle of the ultrasonic vibration system, the feeding direction is in the plane where the blade 1 is located. Frame connection, the flange type fixed frame is connected by flange 12, flange 16 and support block 15 by hexagon socket head cap screws, and the verticality between flange 12, flange 16 and support block 15 is guaranteed during the connection process. The flange 16 and the machine tool flange 19 are connected by bolts 20, so that the ultrasonic vibration cutting head is combined with the CNC milling and drilling machine to form an ultrasonic vibration cutting processing device with high reliability and good processing performance. Start the ultrasonic generator, transmit the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com