A manufacturing process of soft pottery decorative surface hard shell notebook

A production process, notebook technology, applied in bookkeeping, book covers, printing and other directions, can solve the problems of easy contamination or moth-eaten, low durability, and moth-eaten, etc., and achieves stable chemical properties and considerable durability. , the effect of strong reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described:

[0039] A manufacturing process of a soft pottery decorative surface hard shell notebook, comprising the following steps:

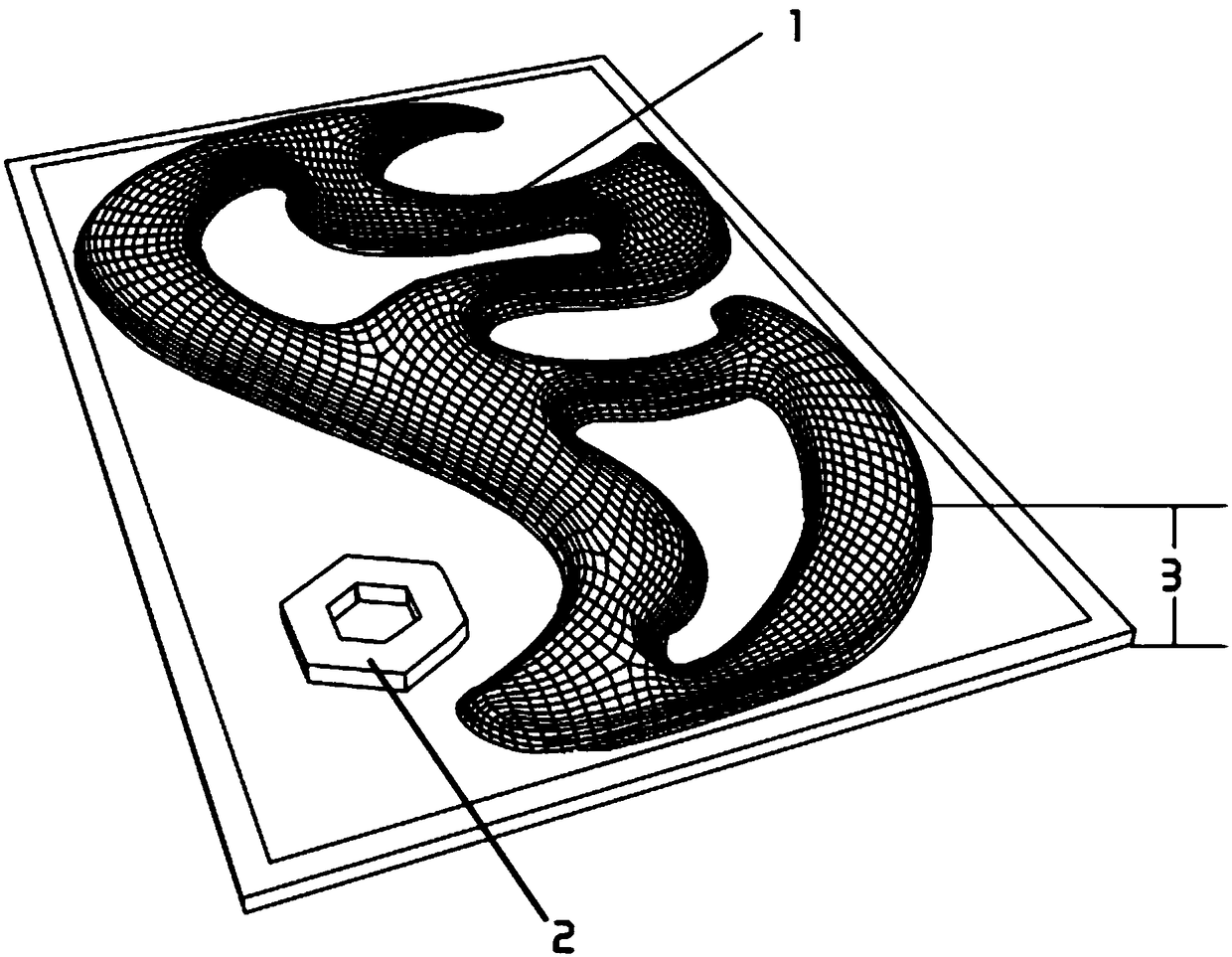

[0040] Step 1: Make the relief sun model

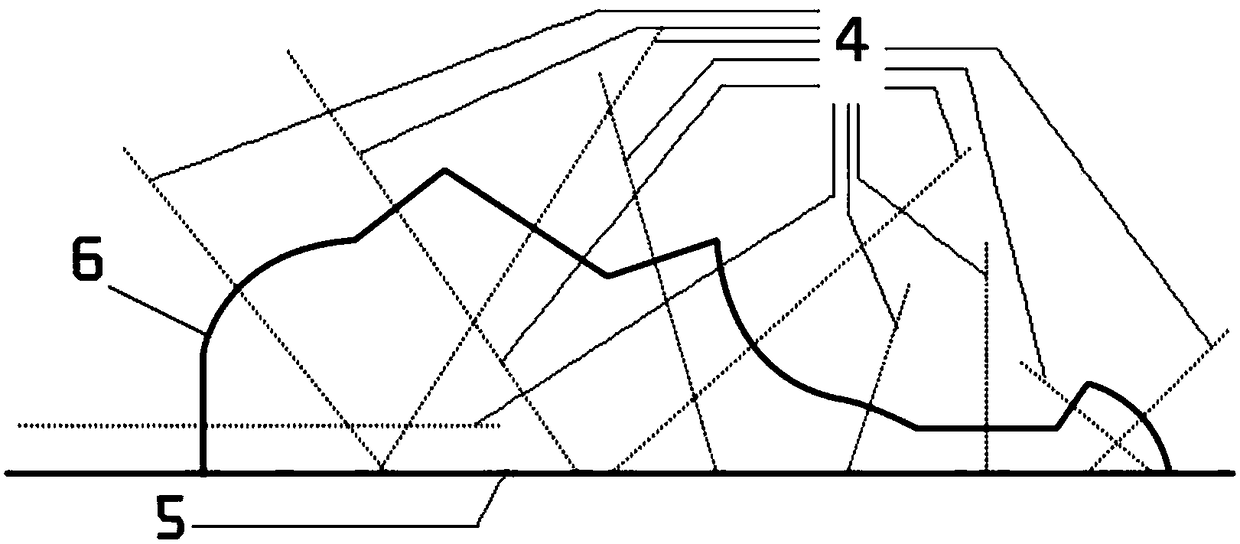

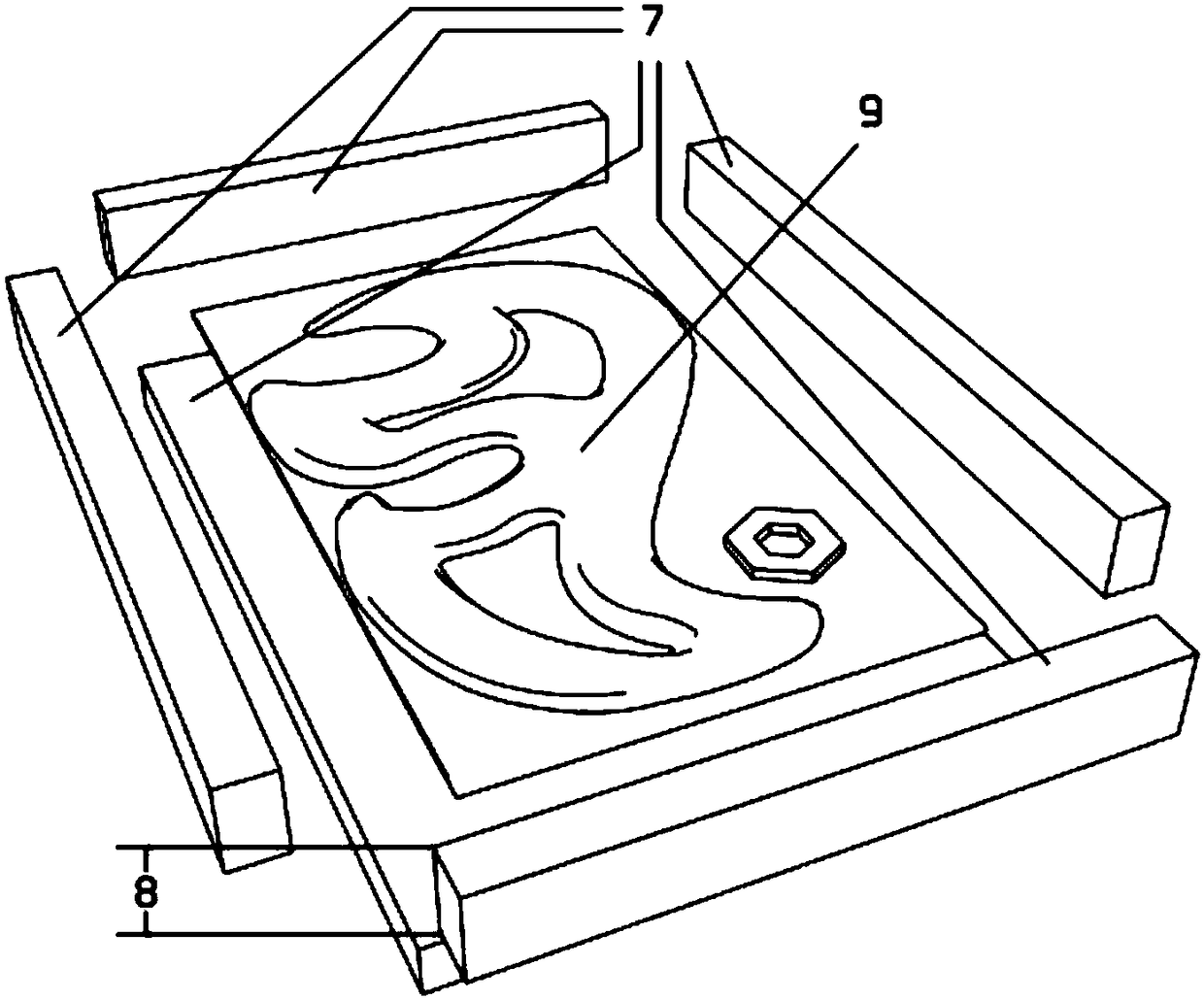

[0041] Such as figure 1 As shown, according to the size of the notebook to be made in the future, use carved oil clay and other materials suitable for sculpture to make a relief model 1 on the positive side. Visible embossed positive side model side height 3. During this period, various physical materials such as metal, plastic, stone, wood, glass, etc. can also be embedded in finely carved oil clay to make it a part of the positive relief model. Such as figure 2As shown, the positive model needs to have a certain hardness at room temperature, and the surface 6 of the model is open, and the angle between the surface normal 4 and the bottom surface 5 of the positive model must be greater than or equal to 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com