Tipping base paper production line and papermaking technology of tipping base paper

A technology of tipping base paper and papermaking technology, which is applied in papermaking, papermaking machines, textiles and papermaking, etc. It can solve the problems of hair loss in long fiber ratio, uncontrollable powder shedding, large degree of fiber treatment, and aggravated lint and powder shedding. , to achieve the effect of improving the tipping base paper production line and tipping base paper papermaking process, improving hair loss, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

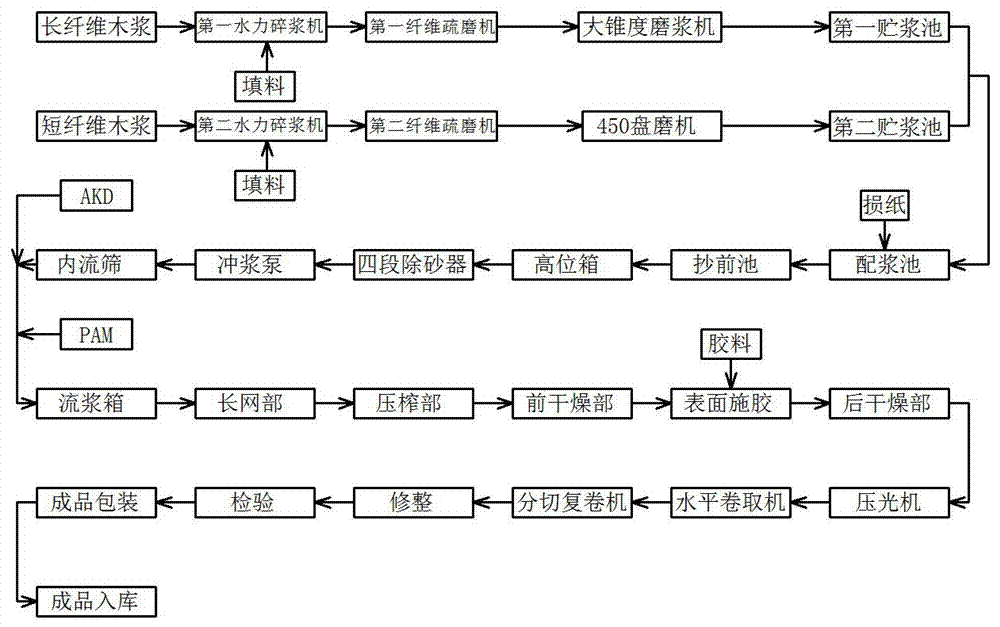

[0037] Such as figure 1 As shown, the base paper production line for tipping includes the pulp making section, the pulp mixing tank, the forecourt tank, the high level box, the four-stage desander, the pulp pump, the internal flow screen, the headbox, the upper section, and the pressing section. , drying section, calender, horizontal coiler, slitter rewinder.

[0038] The pulping department includes the long-fiber wood pulp pulping department and the short-fiber wood pulp pulping department:

[0039] The long fiber wood pulp pulping section includes the first pulper, the first fiber refiner, the large taper refiner and the first pulp storage tank arranged in sequence;

[0040] The short fiber wood pulp pulping section includes a second pulper, a second fiber refiner, a 450 disc refiner and a second pulp storage tank arranged in sequence.

[0041] The drying section includes a front drying section and a rear drying section, and a surface sizing section is arranged between the...

Embodiment 2

[0044] Such as figure 1 As shown, the tipping base paper papermaking process includes the following processes: pulping, pulping, screening and purification, online forming, pressing, drying, calendering, curling, rewinding, trimming, inspection, finished product packaging, and storage.

[0045] In the pulping process, the long-fiber wood pulp passes through the first pulper, the first fiber refiner, and the large-taper refiner in sequence, and enters the first pulp storage tank. Fillers are added to the long fiber wood pulp when it passes through the first pulper. The beating degree of long fiber wood pulp is controlled at 60°SR, the beating concentration is controlled at 3.2%, and the wet weight of beating is controlled at 8.5g;

[0046] In the pulping process, the short-fiber wood pulp passes through the second pulper, the second fiber refiner, and the 450 disc refiner in sequence, and enters the second pulp storage tank. Fillers are added when the short fiber wood pulp pa...

Embodiment 3

[0065] Such as figure 1 As shown, the tipping base paper papermaking process includes the following processes: pulping, pulping, screening and purification, online forming, pressing, drying, calendering, curling, rewinding, trimming, inspection, finished product packaging, and storage.

[0066] In the pulping process, the long-fiber wood pulp passes through the first pulper, the first fiber refiner, and the large-taper refiner in sequence, and enters the first pulp storage tank. Fillers are added to the long fiber wood pulp when it passes through the first pulper. The beating degree of long-fiber wood pulp is controlled at 65°SR, the beating concentration is controlled at 3.3%, and the wet weight of beating is controlled at 9g;

[0067] In the pulping process, the short-fiber wood pulp passes through the second pulper, the second fiber refiner, and the 450 disc refiner in sequence, and enters the second pulp storage tank. Fillers are added when the short fiber wood pulp pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com