Activated carbon filter, its manufacturing process, air purifier and its application

A technology of activated carbon filter screen and activated carbon powder, which is applied in the field of air purification, can solve the problems of limited contact area of activated carbon and low formaldehyde absorption, and achieve the effects of improving formaldehyde purification efficiency, expanding contact area and reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

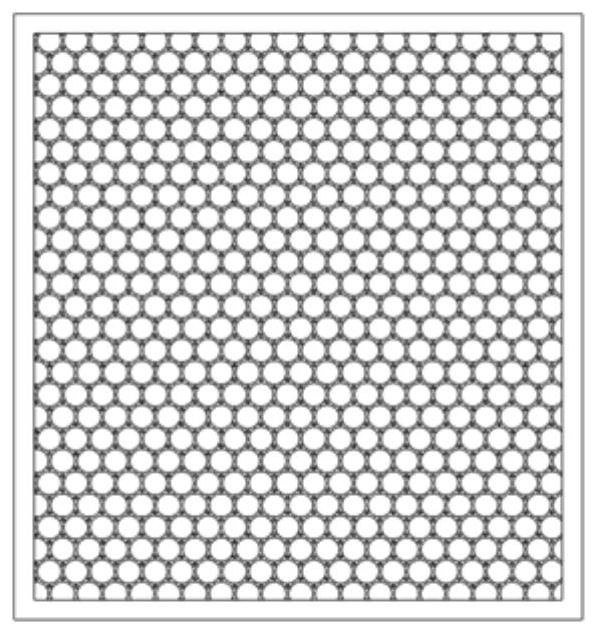

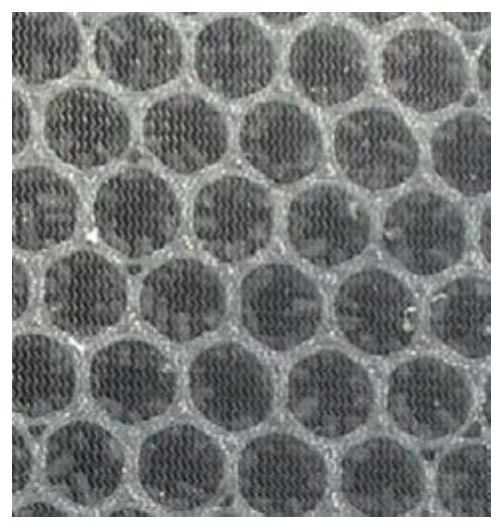

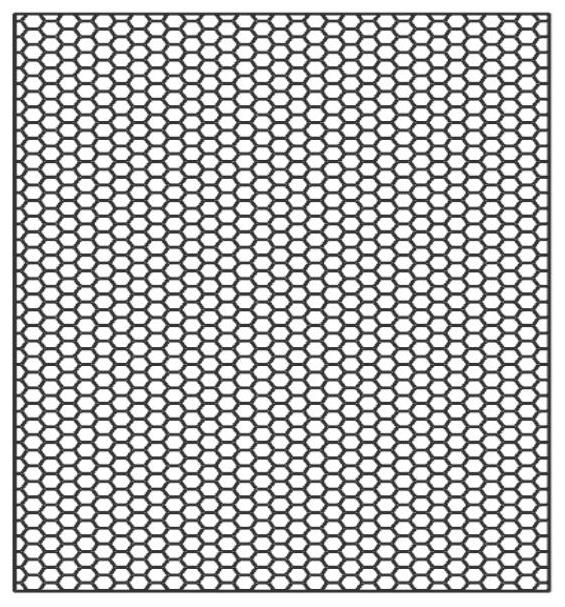

[0083] An activated carbon filter screen, comprising an aluminum honeycomb carrier and a PP honeycomb carrier bonded to each other on one side, several honeycomb grids of the aluminum honeycomb carrier are hexagonal, powdery coconut shell charcoal adheres to the surface, and several honeycomb-shaped grids of the PP honeycomb carrier The grid is circular, and the cylindrical coal-based carbon is adhered to the surface.

[0084] The manufacturing process of the above-mentioned activated carbon filter screen comprises the following steps:

[0085] (1) Put the hexagonal aluminum honeycomb carrier and the circular PP honeycomb carrier into the adhesive and soak them independently, take them out, bake them and dry them in the air;

[0086] (2) Adhering powdery coconut shell charcoal on the hexagonal aluminum honeycomb carrier, and adhering cylindrical coal-based charcoal on the circular PP honeycomb carrier;

[0087] (3) The two types of honeycombs are polished and smoothed. The al...

Embodiment 2

[0089] An activated carbon filter screen, including a magnesium honeycomb carrier and a PE honeycomb carrier that are bonded to each other. Several honeycomb grids of the magnesium honeycomb carrier are hexagonal, and powdery coconut shell carbon is adhered to the surface. Several honeycomb-shaped grids of the PE honeycomb carrier The grid is circular, and the cylindrical coal-based carbon is adhered to the surface.

[0090] The manufacturing process of the above-mentioned activated carbon filter screen comprises the following steps:

[0091] (1) Put the hexagonal magnesium honeycomb carrier and the circular PE honeycomb carrier independently into the adhesive to soak, bake and dry after taking it out;

[0092] (2) Adhering powdery coconut shell charcoal on the hexagonal magnesium honeycomb carrier, and adhering cylindrical coal-based charcoal on the circular PE honeycomb carrier;

[0093] (3) The two kinds of honeycombs are polished and smoothed. The magnesium honeycomb and ...

Embodiment 3

[0095]An activated carbon filter screen, comprising a copper honeycomb carrier and a PVC honeycomb carrier bonded to each other on one side, several honeycomb grids of the copper honeycomb carrier are hexagonal, powdery coconut shell charcoal is adhered to the surface, and several honeycomb-shaped meshes of the PVC honeycomb carrier are hexagonal. The grid is circular, and the cylindrical coal-based carbon is adhered to the surface.

[0096] The manufacturing process of the above-mentioned activated carbon filter screen comprises the following steps:

[0097] (1) Put the hexagonal copper honeycomb carrier and the circular PVC honeycomb carrier independently into the adhesive to soak, bake and dry after taking it out;

[0098] (2) Adhering powdery coconut shell charcoal on the hexagonal copper honeycomb carrier, and adhering cylindrical coal-based charcoal on the circular PVC honeycomb carrier;

[0099] (3) The two kinds of honeycombs were polished and smoothed. The copper hon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com