Condensing device used for return water condensing system

A technology of condensing device and condensing system, which is applied in steam/steam condenser, water/sewage treatment, natural water treatment, etc. It can solve poor condensation effect, reduce the working efficiency of vacuum oil purifier, low working efficiency of condenser, etc. problem, to achieve the effect of solving poor condensation effect, improving cooling efficiency, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

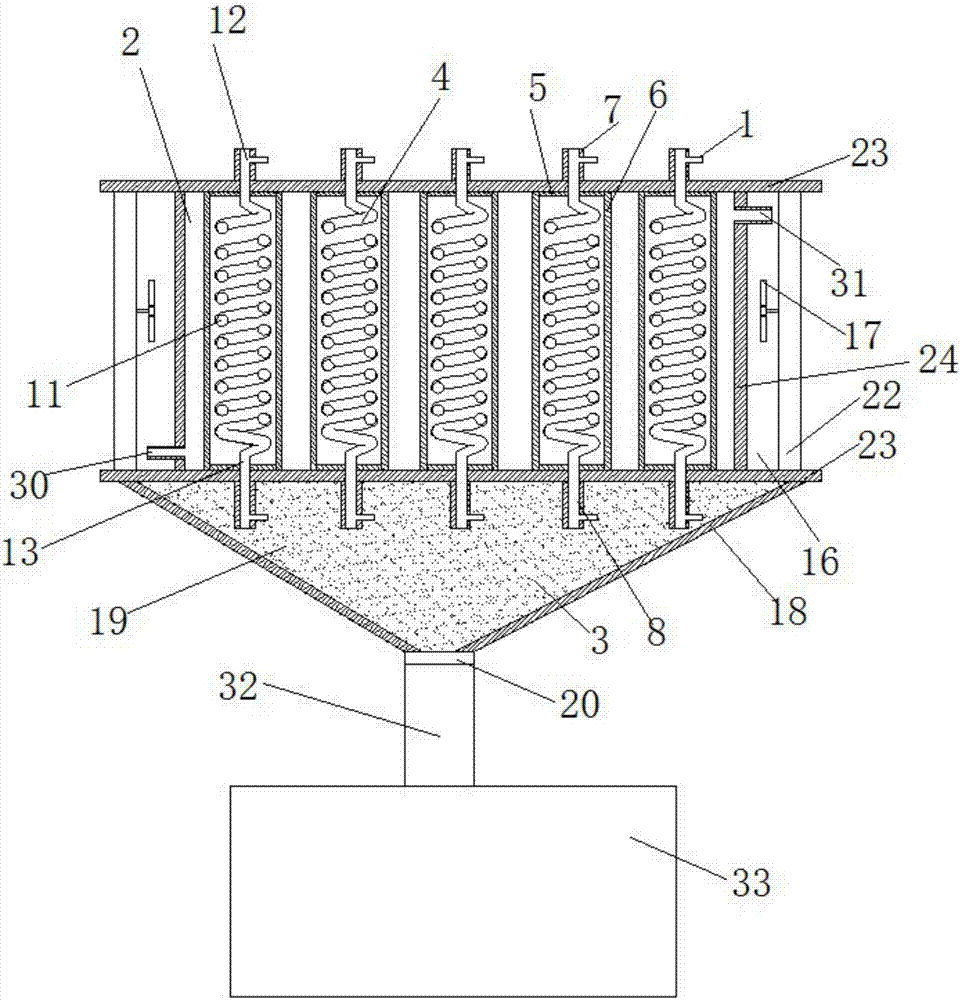

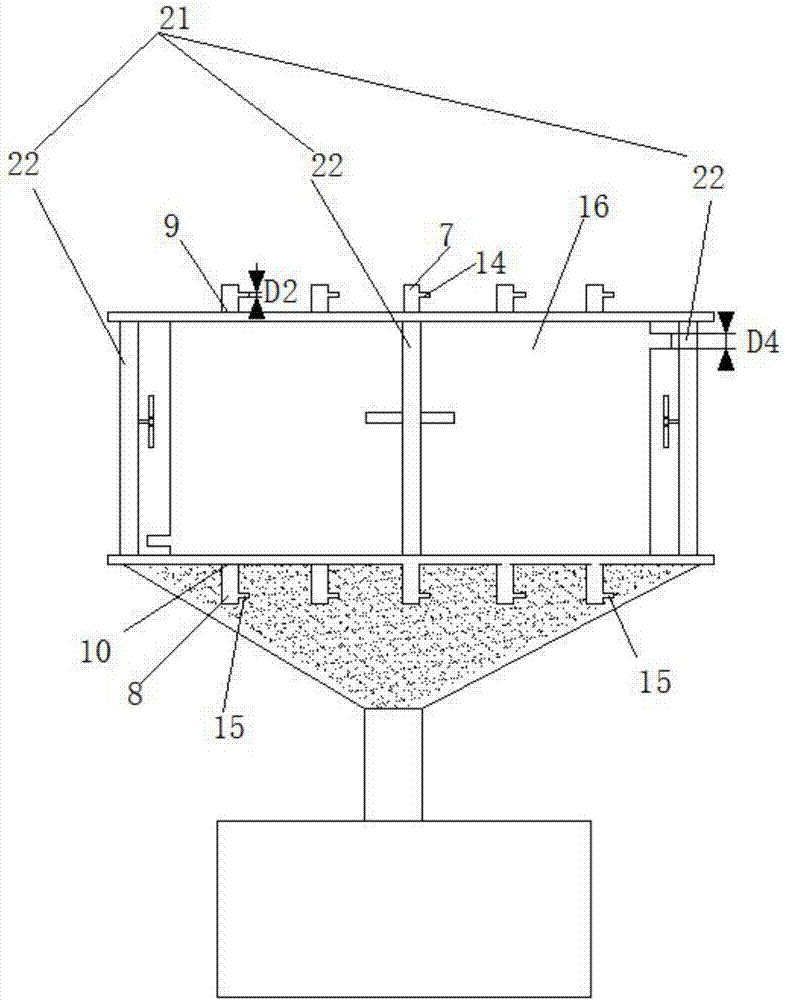

[0018] A condensing device for a return water condensing system, comprising a first condensing device, a second condensing device, a purification device, a mounting frame, and an activated carbon adsorbent;

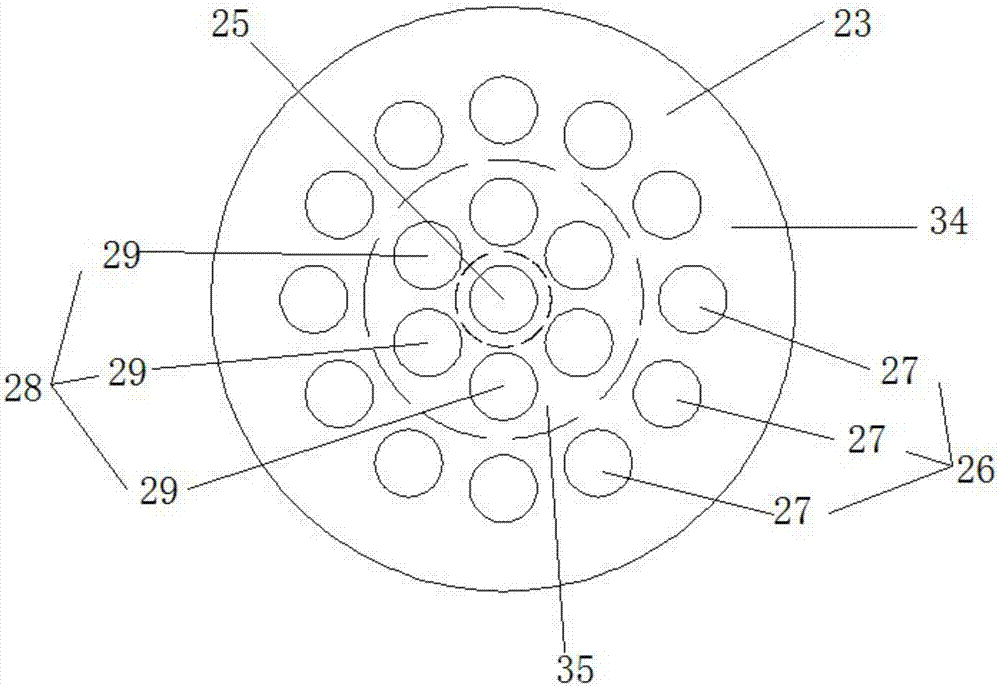

[0019] The first condensing device includes a condensation pipe and a confluence pipe. The confluence pipe includes a liquefaction pipe, an air inlet pipe, and a first liquid outlet pipe. The liquefaction pipe is a hollow structure. The top of the liquefaction pipe is provided with an air inlet, and the bottom is provided with a liquid outlet. The inlet pipe is connected to the liquefaction pipe through the air inlet, and the first liquid outlet pipe is connected to the liquefaction pipe through the liquid outlet; the condensation pipe includes a disk-shaped condensation pipe, a first condensation pipe, and a second condensation pipe, and the upper end of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com