Construction site dust purifying method

A construction site, dust purification technology, applied in the direction of chemical instruments and methods, separation methods, cleaning methods and appliances, etc., can solve construction waste, dust pollution, noise pollution, dust pollution can not achieve a good barrier effect, residents' life and The impact of the surrounding environment and other issues, to achieve the effect of strong applicability and prevent flying around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

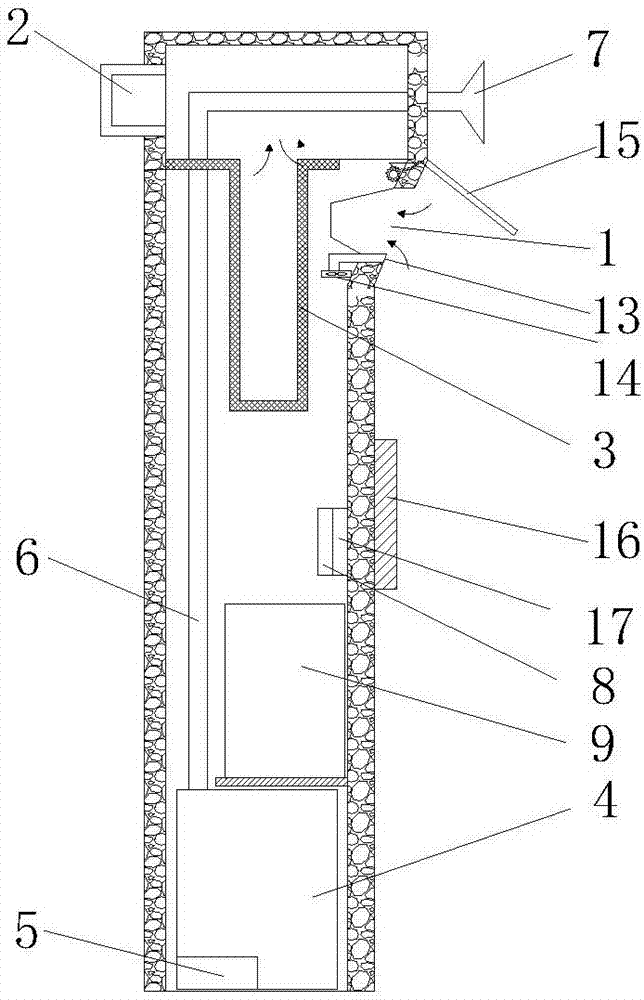

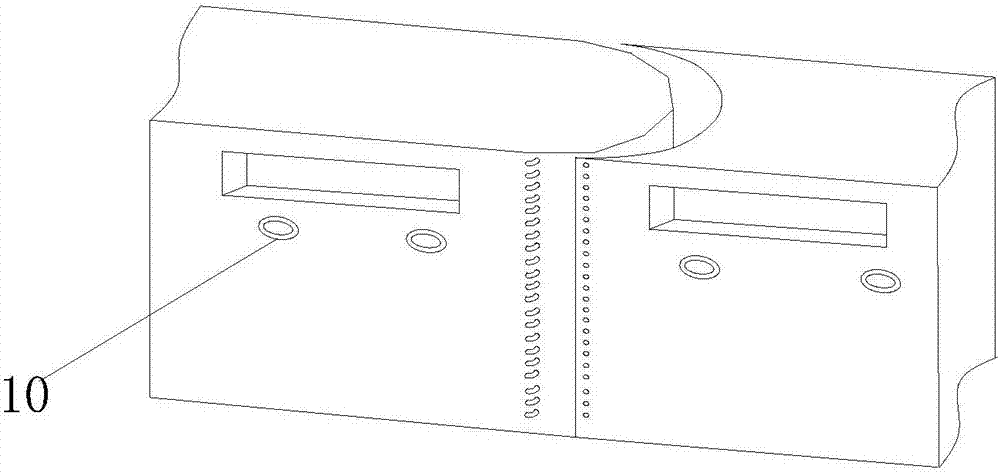

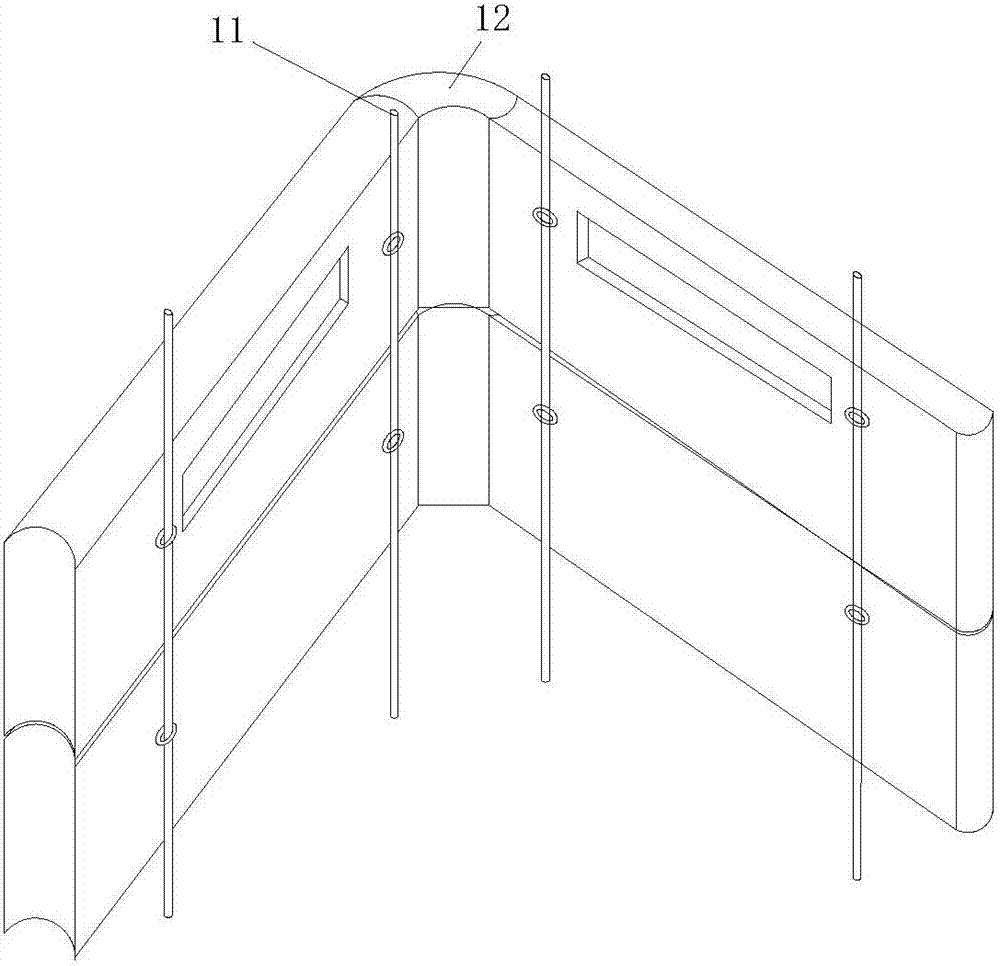

[0032] Such as figure 1 As shown, based on a fence, the fence includes a plurality of prefabricated fence units, and a plurality of prefabricated fence units are connected and fixed between two to form a large fence; each prefabricated fence unit is provided with buckles on the side walls on both sides After inserting piles through the buckle, it is fixed to the foundation; each prefabricated fence unit has an air inlet and an air outlet, and the prefabricated fence unit is provided with an airflow channel for communicating with the air inlet and the air outlet; The filter bag is suspended on the air flow channel, and the air inlet of the prefabricated enclosure unit faces the filter bag; one end of the airflow duct is connected to the air outlet of the prefabricated enclosure unit, and the other end is connected to the first negative pressure device; it can generate The device of water curtain or / and water mist, comprises water tank, water pipe, water pump and sprinkler head,...

Embodiment 2

[0045] The difference between embodiment 2 and embodiment 1 is that the connection structure between the prefabricated enclosure units in the transverse direction is changed from the original hook and pull hole to the magnetic connection through the electromagnetic device. Compared with the connection combination structure of embodiment 1 , the connection speed of embodiment 2 is faster, and the construction efficiency is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com