Rotary cultivator tool apron and manufacturing method thereof

A manufacturing method and the technology of a rotary tiller, which are applied in the field of agricultural machinery, can solve the problems of affecting the normal operation of the rotary tiller, being prone to breakage and damage, and the uniformity of the knife holder, etc. The effect of enhanced welding firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

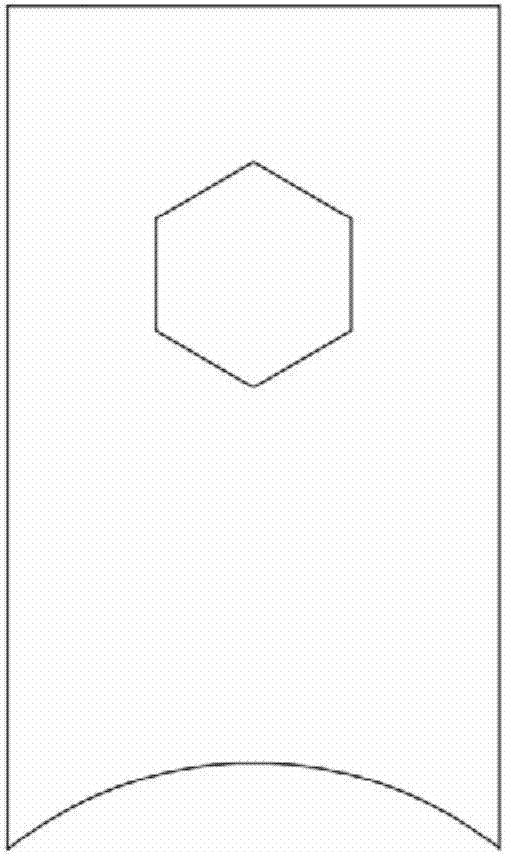

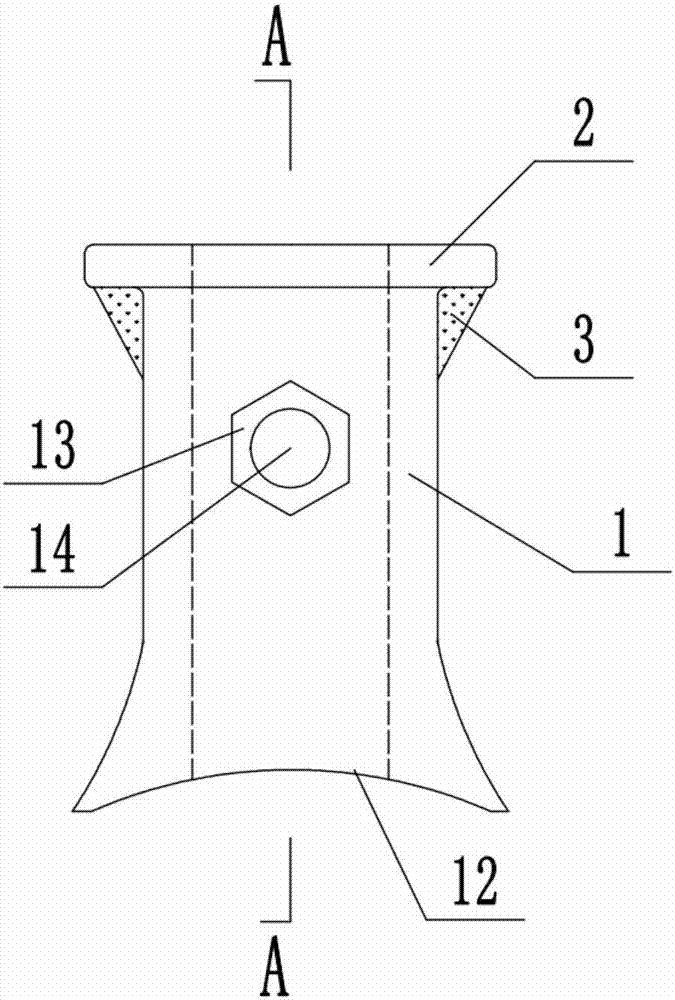

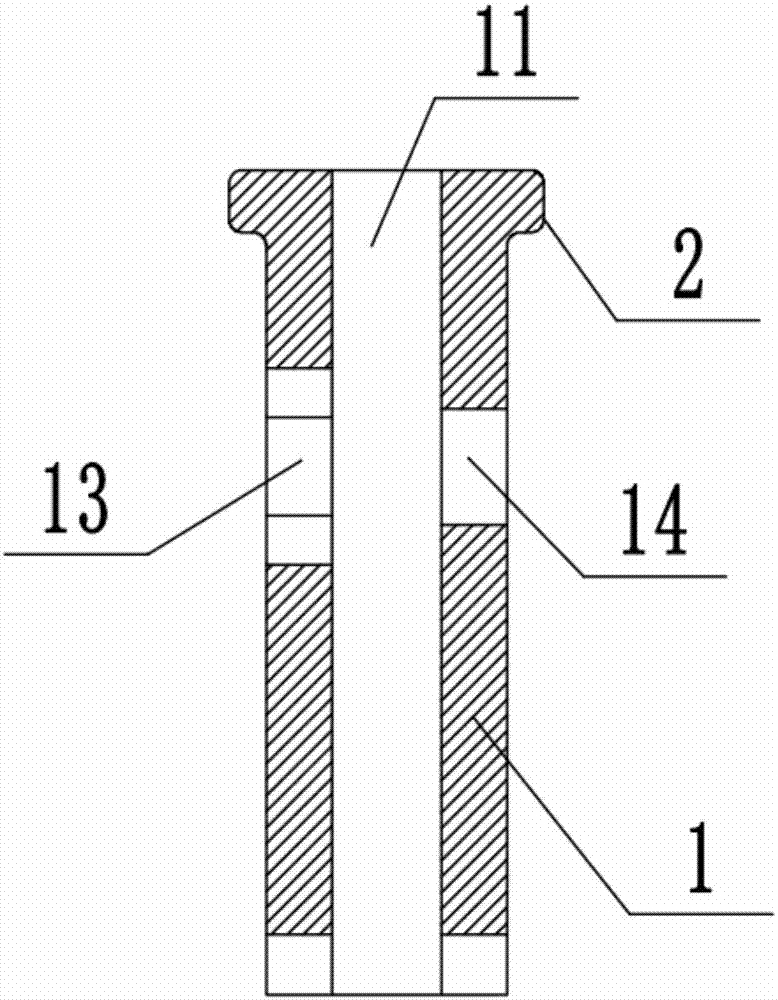

[0043] A rotary tiller blade holder, such as Figure 2~5As shown, it includes a knife seat body 1, a reinforcement eaves 2 and a reinforcement rib 3; the knife seat body 1 is a hollow steel pipe with rounded corners, which is made of thick-walled seamless cold-rolled steel pipe, and its front side wall and rear side wall It is a wider side wall, and the left side wall and the right side wall are narrower side walls; a rectangular blade jack 11 is provided through the center of the knife holder body 1, and the size of the blade jack 11 matches the mounting end of the blade. The upper end of said knife seat body 1 is a plane, and its lower end is an arc surface 12 extending to the left and right sides. The radius of the arc surface 12 coincides with the outer diameter of the rotary cultivator knife shaft. The transverse width of its upper end. A regular hexagona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com