Method for synthesizing hydrogen peroxide through microbiological electrochemical system

A microbial electrochemistry, hydrogen peroxide technology, applied in chemical instruments and methods, inorganic chemistry, electrolysis process, etc., can solve the problems of high energy input, high energy consumption, etc., to achieve treatment, reduce energy consumption, reduce intermediate harmful products The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

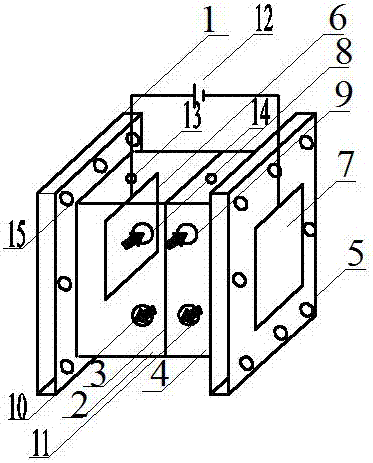

Embodiment 1

[0021] A microbial electrochemical system for synthesizing hydrogen peroxide, which includes an anode chamber baffle 1, an anode chamber 2, a cation exchange membrane 3, a cathode chamber 4, and a cathode chamber baffle in order of assembly from left to right 5. An anode 6 is built in the anode chamber, and a cathode 7 is built in the cathode chamber. The anode is exported from the anode outlet 13 through a graphite rod, and the cathode is exported through a stainless steel gasket; the anode chamber is respectively provided with an anode chamber feed port 8, Anode chamber outlet 10, anode outlet 13; cathode chamber inlet 9, cathode chamber outlet 11, cathode outlet 14 are respectively opened on the cathode chamber; connecting thread port 15 is connected to the anode chamber by bolts The chamber baffle plate 1 and the cathode chamber baffle plate 5 squeeze the whole device together, and gaskets are required between each part to ensure the sealing of the system.

[0022] The ano...

Embodiment 2

[0025] A method for synthesizing hydrogen peroxide using the microbial electrochemical system described in Example 1.

[0026] To start a microbial electrochemical system for synthesizing hydrogen peroxide, the anaerobic anode chamber is filled with the following ratio of materials, inoculum: substrate + pH buffer = 1:9; the aerobic cathode chamber is filled with pH buffer Liquid; 0.5V voltage is applied between the anode and the cathode.

[0027] After a successful start-up of the system, only the digested substrate is fed into the anode compartment, no inoculum needs to be added.

[0028] Preferably, the cathode outlet 14 is additionally equipped with a small peristaltic pump and H 2 o 2 Purification system.

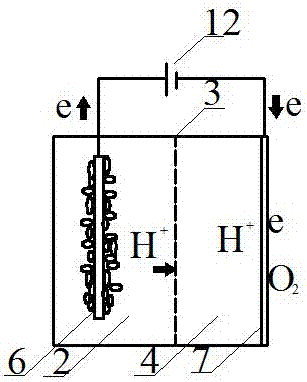

[0029] The working principle of the second embodiment is as follows: the substrate in the anode chamber 2 is digested by anaerobic microorganisms attached to the anode 6 to generate electrons (e - ) and hydrogen ions (H + ), resulting in e - Passed from the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com