Pretreatment method of filter assembly of drinking water processor

A technology of filter components and processors, which is applied in the field of drinking water treatment and can solve the problems of low water purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

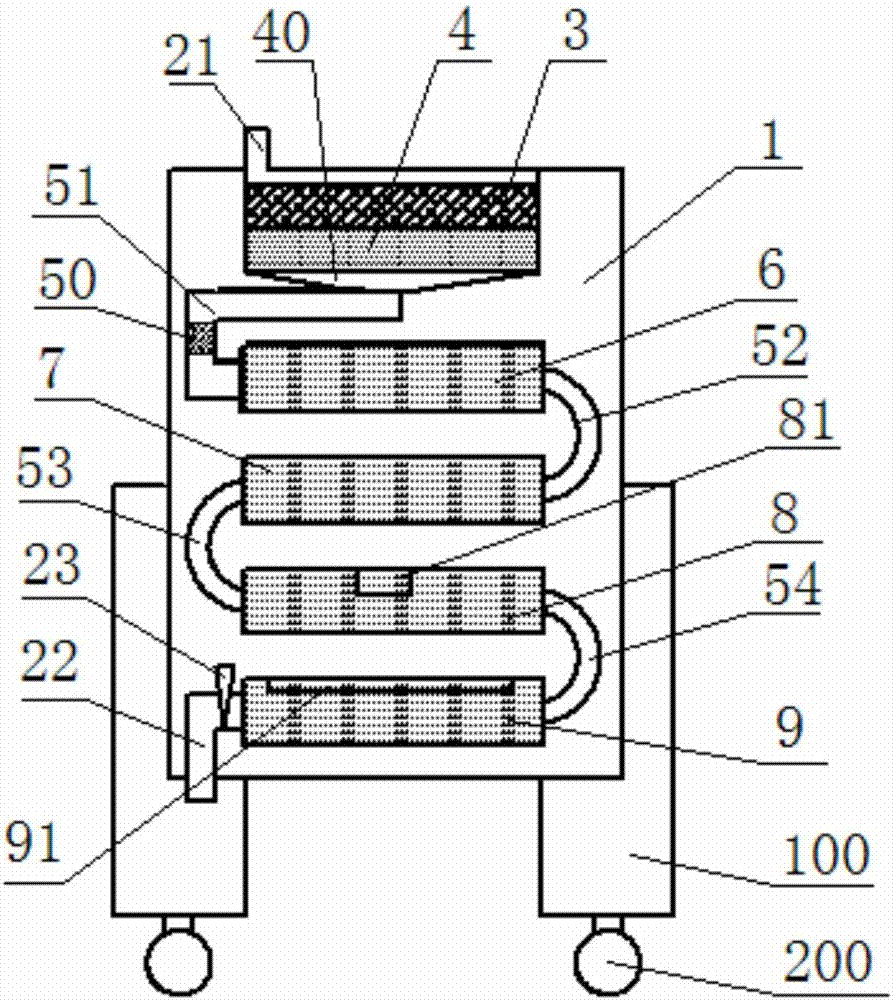

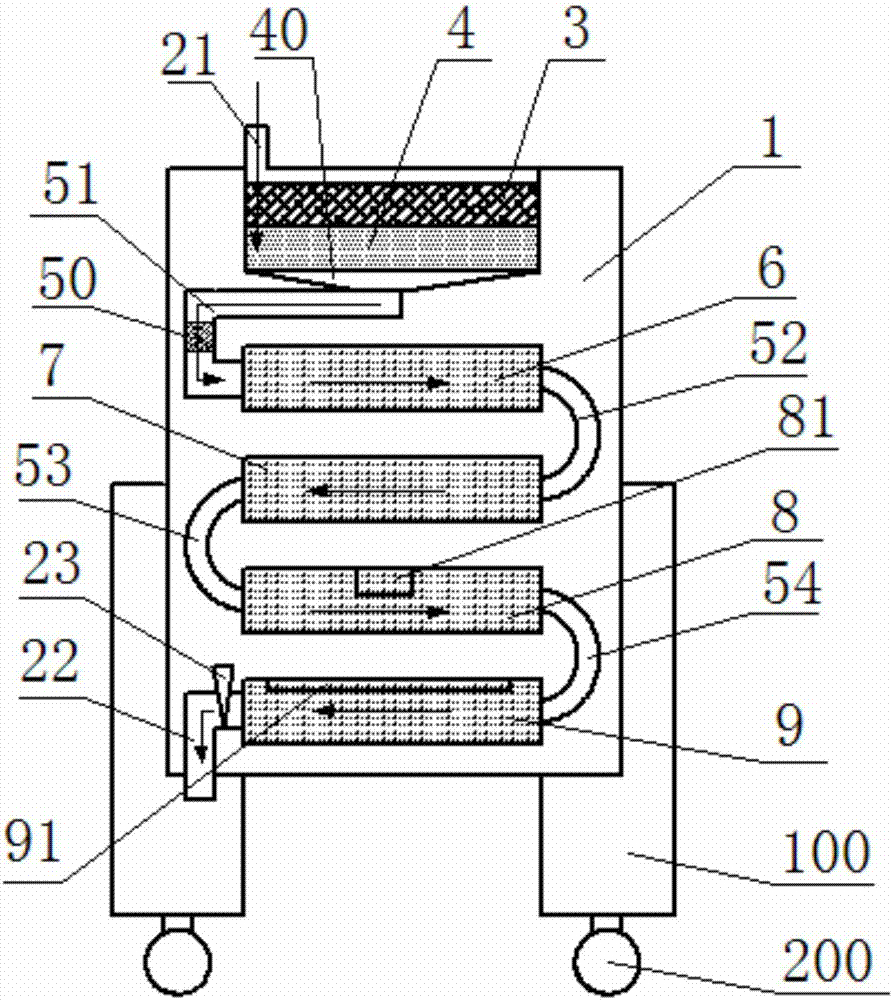

[0029] Such as Figure 1 to Figure 2 As shown, the present invention provides a drinking water processor, comprising: a box body 1, a water inlet 21 located at the top of the box body 1, a bio-cotton layer 3 arranged on the inside of the box body 1 and connected to the water inlet 21, a device The quartz sand layer 4 below the biological cotton layer 3, the funnel 40 located below the quartz sand layer 4, the first water pipe 51 communicated with the funnel 40, the first filter element 6 communicated with the first water pipe 51, and the first filter element 6 The second water pipe 52 communicated, the second filter element 7 communicated with the second water pipe 52, the third water pipe 53 communicated with the second filter element 7, the third filter element 8 communicated with the third water pipe 53, the third filter element 8 communicated with The fourth water pipe 54, the fourth filter element 9 communicated with the fourth water pipe 54, the water outlet 22 communica...

Embodiment 2

[0040] A pretreatment method for a filter assembly of a drinking water processor, the steps are as follows:

[0041] ①. Assembly of filter components and installation of components

[0042] The filter assembly is composed of bio-cotton layer, quartz sand layer, ceramic filter element, granular activated carbon filter element, ultrafiltration membrane filter element, reverse osmosis membrane filter element and connecting pipelines. The bio-cotton layer is in direct contact with the quartz sand layer. There is a polypropylene fiber filter screen on the pipeline between them, a magnetized body is installed in the ultrafiltration membrane filter element, and an infrared lamp or an ultraviolet lamp is installed inside the reverse osmosis membrane filter element;

[0043] ②, soak in the pretreatment solution

[0044] Insert the pretreatment solution from the bio-cotton layer, keep the flow rate at 50mL / min, and keep it connected for more than 12 hours since all parts are fully impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com