Doped ultra-low expansion glass and methods for making the same

A glass product and glass technology, which is applied to doped ultra-low expansion glass and its field, can solve problems such as difficulty in achieving specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

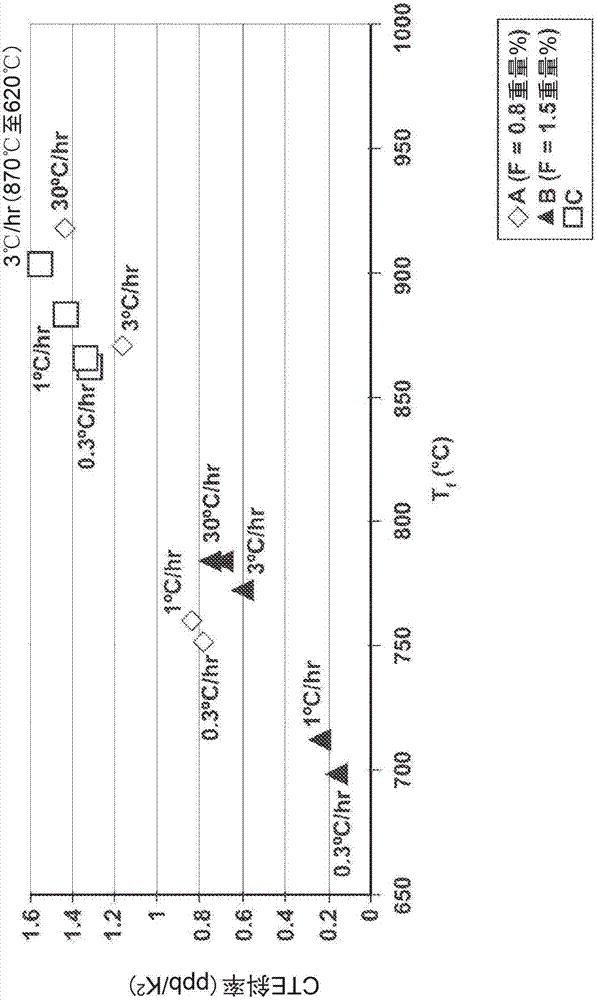

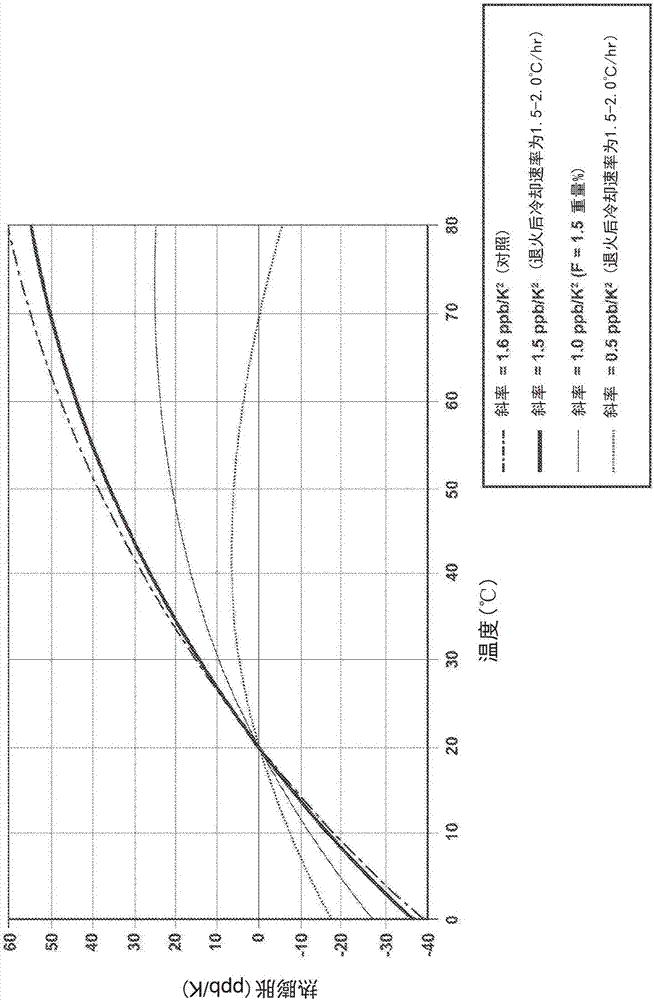

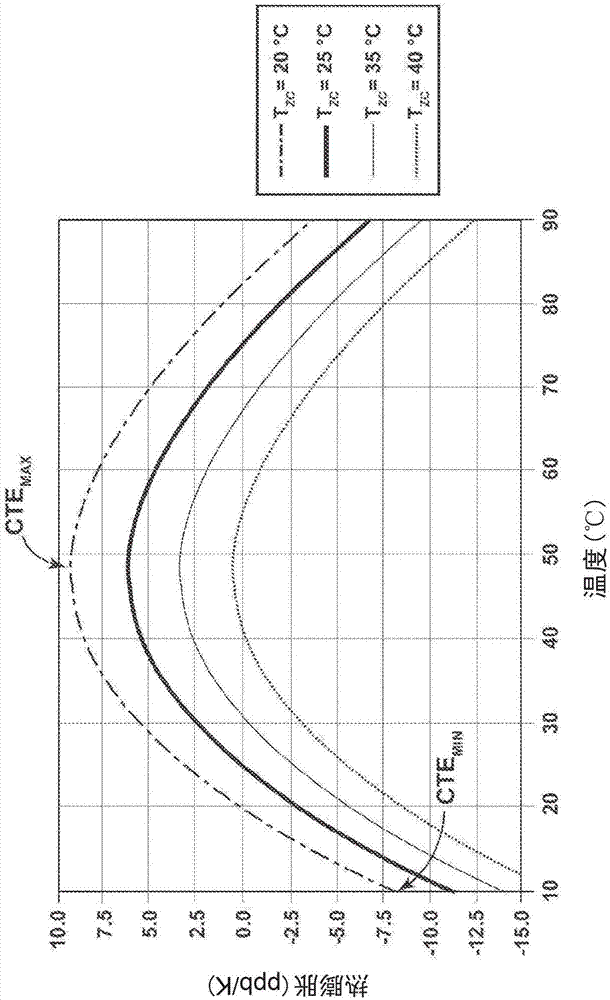

Embodiment 1

[0059] by separate flame hydrolysis of TiCl 4 and SiCl 4 Titanium dioxide and silica soot particles were fabricated and the soot was deposited on a lathe bait rod using an OVD process for approximately 16.5 hours. The soot body thus produced had a mass of 6010 g, a density of 0.43 g / cc and a diameter of 135.2 mm. The soot body was then consolidated in a muffle furnace as follows: heating to 1125° C. for 60 minutes in flowing He (5 slpm—standard liters per minute). Then, by passing 0.15slpm Cl in the furnace 2 gas and 5 slpm He, at 1125°C for an additional 120 minutes to dry the soot body. Next, by flowing 4.96 slpm He, 0.04 slpm O at 1125°C 2 and 0.75slpm SiF 4 , flow for 40 min to purge Cl. Finally, with 4.96slpm He, 0.04slpm O 2 and 0.75slpm SiF 4 The green bodies were sintered at a peak temperature of 1385° C. and a downward drive speed of 6 mm / min in a muffle furnace to obtain a target F concentration of 1.5 wt % in the glass. Due to TiO 2 The presence of crystal...

Embodiment 2

[0062] by separate flame hydrolysis of TiCl 4 and SiCl 4 Titanium dioxide and silica soot pellets were fabricated and the soot was deposited on a bait rod on a lathe using the OVD process for approximately 16.5 hours. The soot body thus produced had a mass of 5992 g, a density of 0.42 g / cc and a diameter of 135.7 mm. The soot body was then consolidated in a muffle furnace as follows: heating to 1125° C. for 60 minutes in flowing He (5 slpm—standard liters per minute). Then, by passing 0.15slpm Cl in the furnace 2 gas and 5 slpm He, at 1125°C for an additional 120 minutes to dry the soot body. Next, Cl was purged by flowing 5 slpm He at 1125°C for 30 minutes. Finally, with 4.92slpm He, 0.08slpm O 2 and 0.2slpm SiF 4 The green body was sintered at a peak temperature of 1440° C. and a downward drive speed of 6 mm / min in a muffle furnace to obtain a target F concentration of 0.8 wt % in the glass. Due to TiO 2 The presence of crystallites, therefore, the color of the forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com