Diaphragm for alkaline water electrolysis, alkaline water electrolysis apparatus, method for producing hydrogen, and method for producing diaphragm for alkaline water electrolysis

A manufacturing method and technology of water electrolysis, applied in the direction of diaphragm, electrolysis process, electrolysis components, etc., can solve the problem of increasing the voltage loss of the diaphragm, and achieve the effect of maintaining low voltage loss, good gas barrier properties, and inhibiting ion permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

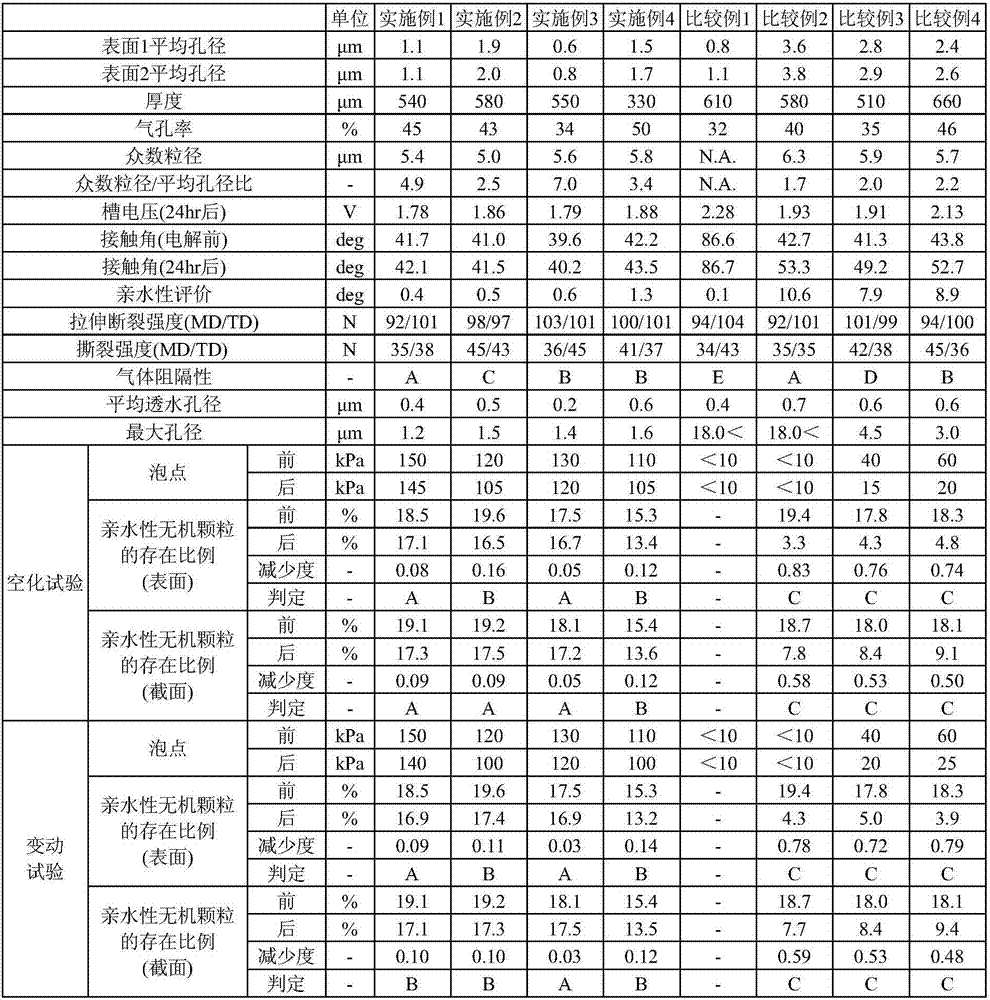

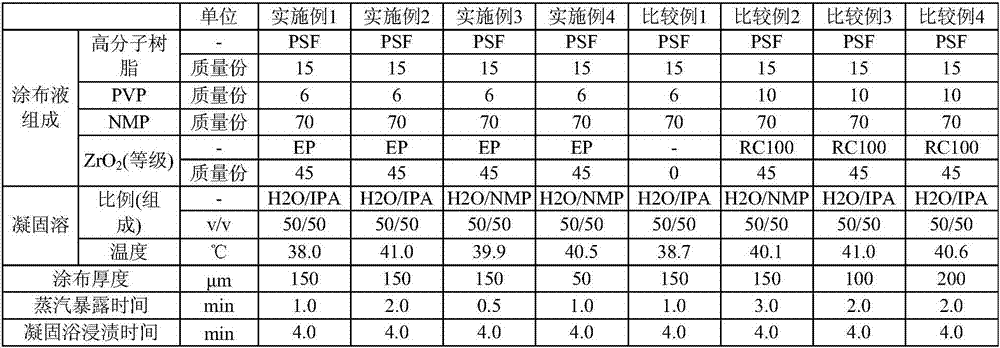

[0290] Put 135 g of zirconia ("EP zirconia", manufactured by Daiichi Xen Element Chemical Industry Co., Ltd.) and 210 g of N-methyl-2-pyrrolidone (manufactured by Wako Pure Chemical Industries, Ltd.) into 1 kg of SUS balls with a particle size of 0.5 mm In a ball mill kettle with a capacity of 1000mL. This was stirred at a rotation speed of 70 rpm for 3 hours in an atmosphere of 25° C., and dispersed to obtain a mixture. The resulting mixture was filtered through a stainless steel basket (30 meshes), and balls were separated from the mixture. 45 g of polysulfone ("Udel" (trademark), manufactured by Solvay Advanced Polymers Co., Ltd.) and 18 g of polyvinylpyrrolidone (weight average molecular weight (Mw) 900,000, manufactured by Wako Pure Chemical Industries, Ltd.) were added to the mixture from which the spheres were separated, and stirred The Three-One Motor was stirred at 60° C. for 12 hours to dissolve, and a coating liquid having the following composition was obtained.

...

Embodiment 2

[0298] Put 135 g of zirconia ("EP zirconia", manufactured by Daiichi Xen Element Chemical Industry Co., Ltd.) and 210 g of N-methyl-2-pyrrolidone (manufactured by Wako Pure Chemical Industries, Ltd.) into 1 kg of SUS balls with a particle size of 0.5 mm In a ball mill kettle with a capacity of 1000mL. This was stirred at a rotation speed of 70 rpm for 3 hours in an atmosphere of 25° C., and dispersed to obtain a mixture. The resulting mixture was filtered through a stainless steel basket (30 meshes), and balls were separated from the mixture. 45 g of polysulfone ("Udel" (trademark), manufactured by Solvay Advanced Polymers Co., Ltd.) and 18 g of polyvinylpyrrolidone (weight average molecular weight (Mw) 900,000, manufactured by Wako Pure Chemical Industries, Ltd.) were added to the mixture from which the spheres were separated, and stirred The Three-One Motor was stirred at 60° C. for 12 hours to dissolve, and a coating liquid having the following composition was obtained.

...

Embodiment 3

[0306] Put 135 g of zirconia ("EP zirconia", manufactured by Daiichi Xen Element Chemical Industry Co., Ltd.) and 210 g of N-methyl-2-pyrrolidone (manufactured by Wako Pure Chemical Industries, Ltd.) into 1 kg of SUS balls with a particle size of 0.5 mm In a ball mill kettle with a capacity of 1000mL. This was stirred at a rotation speed of 70 rpm for 3 hours in an atmosphere of 25° C., and dispersed to obtain a mixture. The resulting mixture was filtered through a stainless steel basket (30 meshes), and balls were separated from the mixture. 45 g of polysulfone ("Udel" (trademark), manufactured by Solvay Advanced Polymers Co., Ltd.) and 18 g of polyvinylpyrrolidone (weight average molecular weight (Mw) 900,000, manufactured by Wako Pure Chemical Industries, Ltd.) were added to the mixture from which the spheres were separated, and stirred The Three-One Motor was stirred at 60° C. for 12 hours to dissolve, and a coating liquid having the following composition was obtained.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com