Gas fuel burner and method for heating gas fuel burner

A gas fuel and burner technology, which is applied to the heating field of gas fuel burners and gas fuel burners, can solve the problems of slow combustion speed, flame blowing away, inability to speed up the flame flow rate, etc., and achieves the effect of high axial speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

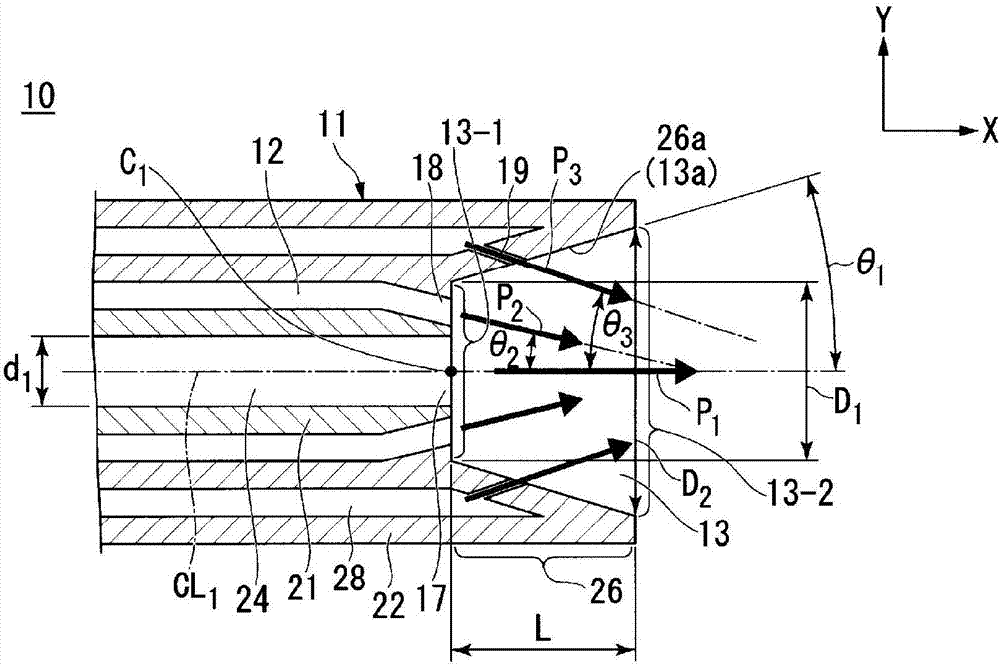

[0040] figure 1 It is a cross-sectional view schematically showing the general structure of a main part of the gas fuel burner according to the first embodiment of the present invention. exist figure 1 Here, the X direction represents the direction in which the burner body 11 extends (in other words, a predetermined direction), and the Y direction represents a direction perpendicular to the X direction.

[0041] In addition, in figure 1 Medium, P 1 Indicates the direction in which the first oxidant is ejected (hereinafter referred to as "the first oxidant ejection direction P 1 ”), P 2 Indicates the direction in which the gaseous fuel is ejected (hereinafter referred to as "the gaseous fuel ejection direction P 2 ”), P3 Indicates the direction in which the second oxidant is ejected (hereinafter referred to as "the second oxidant ejection direction P 3 ").

[0042] refer to figure 1 , The gas fuel burner 10 of the first embodiment has a burner main body 11 , a gas fuel ...

no. 2 approach

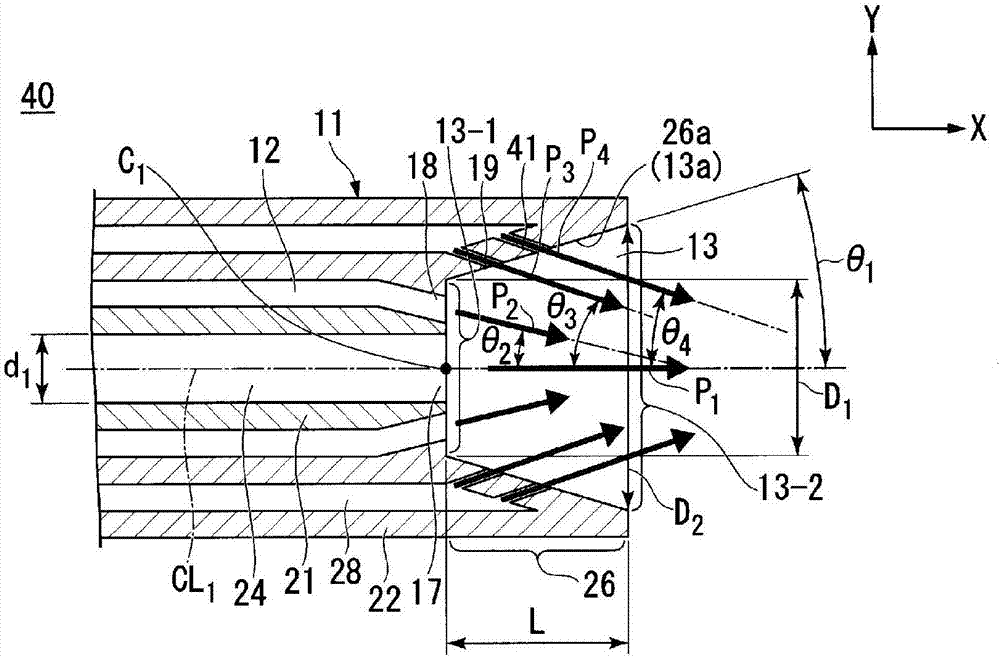

[0107] figure 2 It is a cross-sectional view schematically showing the general structure of a main part of the gas fuel burner according to the second embodiment of the present invention. exist figure 2 Medium, P 4 Indicates the direction in which the third oxidant is ejected (hereinafter referred to as "the third oxidant ejection direction P 4 ").

[0108] In addition, in figure 2 in, right with figure 1 The same structural parts of the gas fuel burner 10 of the first embodiment shown are provided with the same reference numerals.

[0109] figure 2 The gas fuel burner 40 of the second embodiment shown is similar to the gas fuel burner 10 of the first embodiment except that a third oxidant injection port 41 is further provided in the structure of the gas fuel burner 10 of the first embodiment. same.

[0110] In the gas fuel burner 40 of the second embodiment, the third oxidizing agent injection port 40 is provided on the side surface 13 a of the combustion chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com