Mixed ore high-pressure roller grinding wet-type preselected, suspension roasting-magnetic separation process

A technology of high-pressure roller milling and suspension roasting, which is applied in the field of mineral processing, can solve the problems of consuming large flotation reagents, increasing flotation equipment, and reducing the amount of ore feed, and achieves the elimination of flotation reagent dosage, significant economic benefits, and simplified process structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

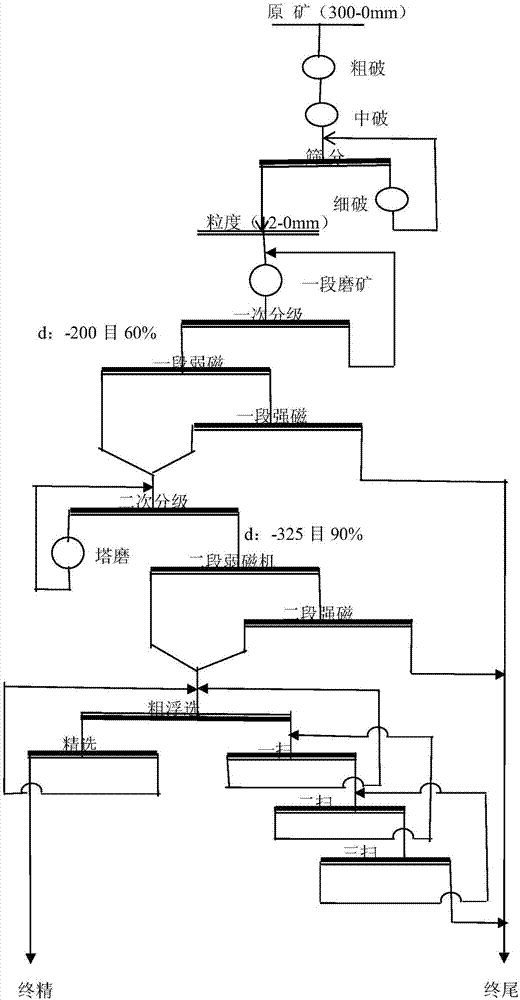

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

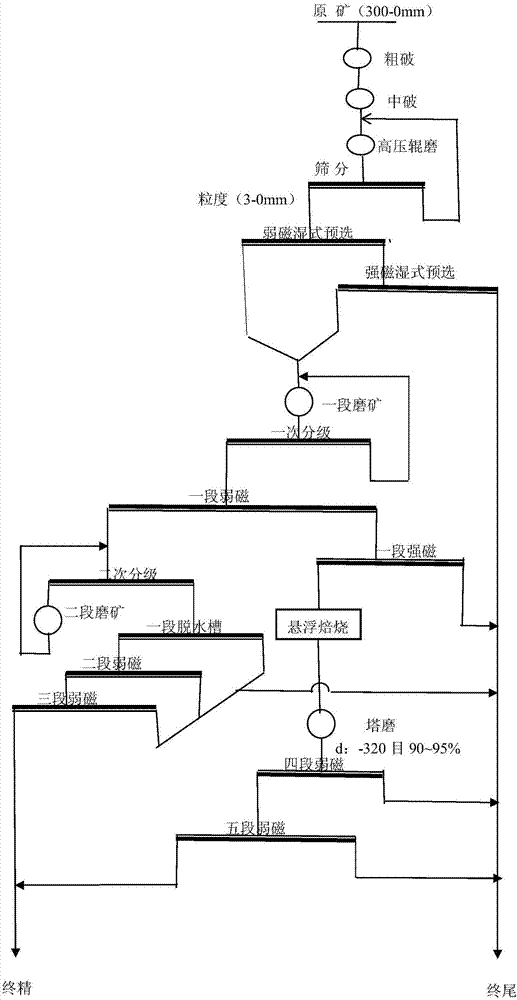

[0017] Such as figure 2 Shown, mixed ore high pressure roller mill wet pre-selection of the present invention, suspension roasting-magnetic separation process is characterized in that comprising the following steps:

[0018] 1) After coarse crushing and medium crushing, the raw ore with an ore grade of 30% to 33% and a particle size of 300-0mm is subjected to high-pressure roller milling and screening to obtain a grinding product with a particle size of 3-0mm;

[0019] 2) Feed the grinding product with a particle size of 3-0mm into a section of weak magnetic wet pre-selection, feed the tailings of a section of weak magnetic wet pre-selection into a section of strong magnetic wet pre-selection, and throw away a section of strong magnetic wet pre-selection. The yield is 18%-20% Coarse tailings with a grade of 6%-7%;

[0020] 3) A section of weak magnetic wet pre-select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com