Preparation method and application of grafting-modified tackifying resin

A tackifying resin, graft modification technology, applied in the direction of graft polymer adhesives, adhesives, adhesive types, etc., can solve the problems of poor compatibility, high cost, affecting large-scale promotion, etc. Good capacitance, good bonding effect and excellent tackifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The graft modified tackifying resin of the present embodiment obtains according to the preparation method of following steps:

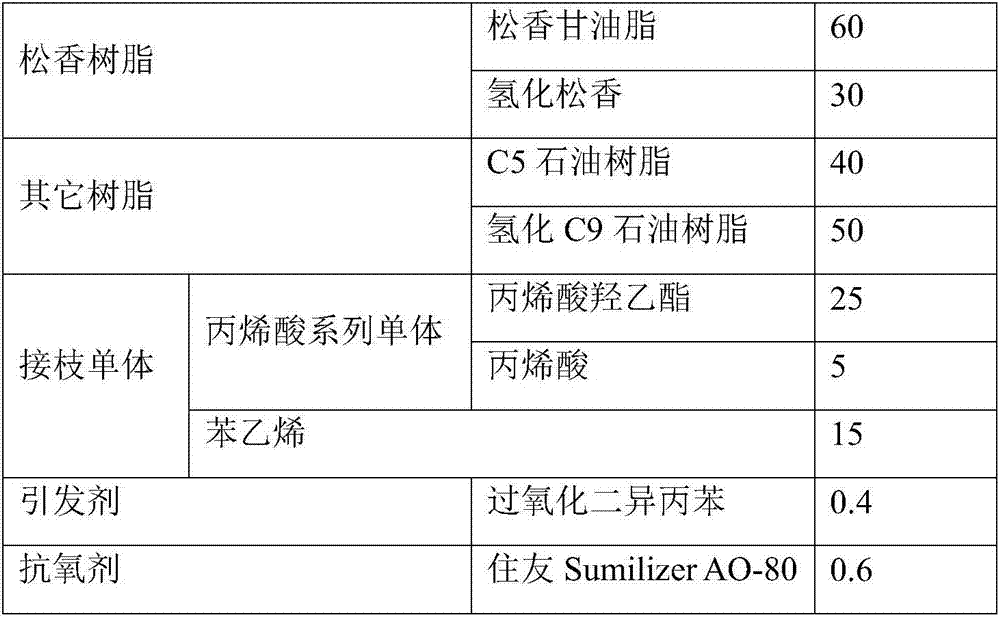

[0032] (1) Take the raw materials of following weight parts:

[0033]

[0034] (2) Rosin resin is crushed, in the dry reactor that thermometer, stirrer, reflux condenser are equipped with, add the rosin resin that pulverizes and other resins, add 40% grafting monomer and antioxidant stirring and dissolving, heat until completely melted;

[0035] (3) add initiator and disperse for 5 minutes again, keep warm for 1 hour;

[0036] (4) drop the remaining grafting monomers to start the grafting reaction, the temperature is controlled at 80-90°C, the dropwise addition is completed in 4 hours, and the temperature is kept for 1.5 hours;

[0037] (5) Cooling and discharging.

[0038] The grafted modified tackifying resin prepared in this example can be used directly as a hot melt adhesive, or as a tackifier for a hot melt adhesive, or as a compatib...

Embodiment 2

[0040] The graft modified tackifying resin of the present embodiment obtains according to the preparation method of following steps:

[0041] (1) Weigh the following raw materials in parts by weight

[0042]

[0043]

[0044] (2) Rosin resin is crushed, in the dry reactor that thermometer, stirrer, reflux condenser are equipped with, add the rosin resin that pulverizes and other resins, add 40% grafting monomer and antioxidant stirring and dissolving, heat until completely melted, and then the temperature is controlled at 70-80°C;

[0045] (3) Add initiator and disperse for 5 minutes;

[0046] (4) Add dropwise the remaining grafting monomers to start the grafting reaction, the temperature is controlled at 80-90° C., the dropwise addition is completed in 3 hours, and the insulation is kept for 1.5 hours;

[0047] (5) Cooling and discharging.

[0048] The grafted modified tackifying resin prepared in this example can be used directly as a hot melt adhesive, or as a tack...

Embodiment 3

[0050] The graft modified tackifying resin of the present embodiment obtains according to the preparation method of following steps:

[0051] (1) Weigh the following raw materials in parts by weight

[0052]

[0053]

[0054] (2) Rosin resin is crushed, in the dry reactor that thermometer, stirrer, reflux condenser are equipped with, add the rosin resin that pulverizes and other resins, add 40% grafting monomer and antioxidant stirring and dissolving, heat until completely melted, and then the temperature is controlled at 70-80°C;

[0055] (3) add initiator and disperse for 5 minutes again, keep warm for 1 hour;

[0056] (4) Add dropwise the remaining grafting monomers to start the grafting reaction, the temperature is controlled at 90-110° C., the dropwise addition is completed in 4.5 hours, and the temperature is kept for 1 hour;

[0057] (5) Cooling and discharging.

[0058] The grafted modified tackifying resin prepared in this example can be used directly as a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com