Water-based drilling fluid and preparation method and application thereof

A water-based drilling fluid and drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient emphasis on environmental protection, achieve environmental protection characteristics, good rheology, and meet the requirements of well wall stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

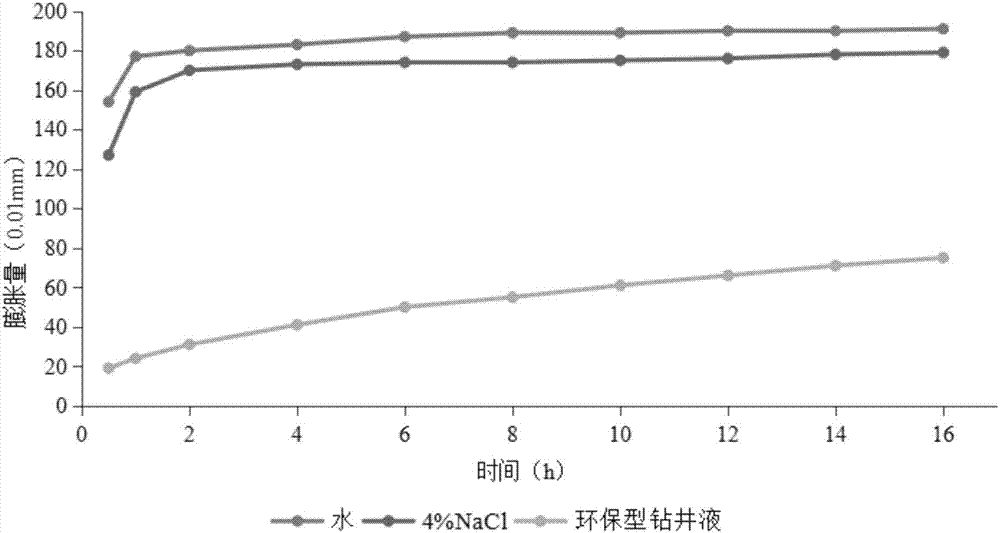

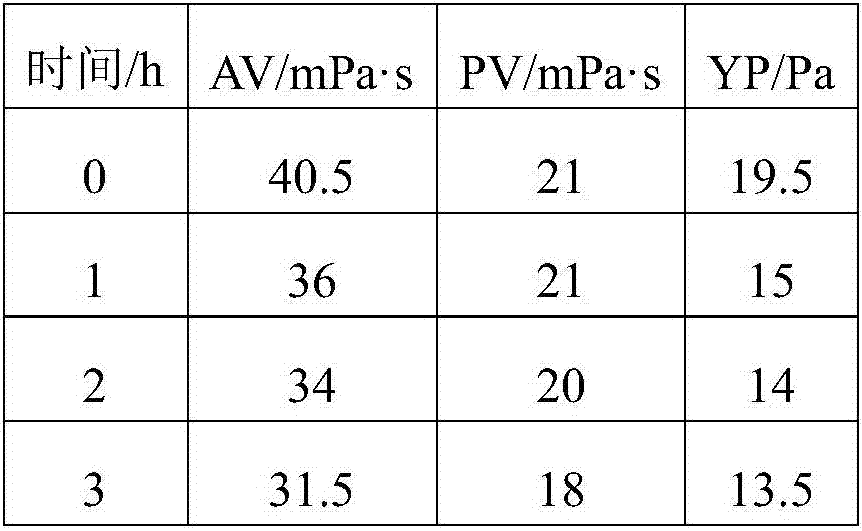

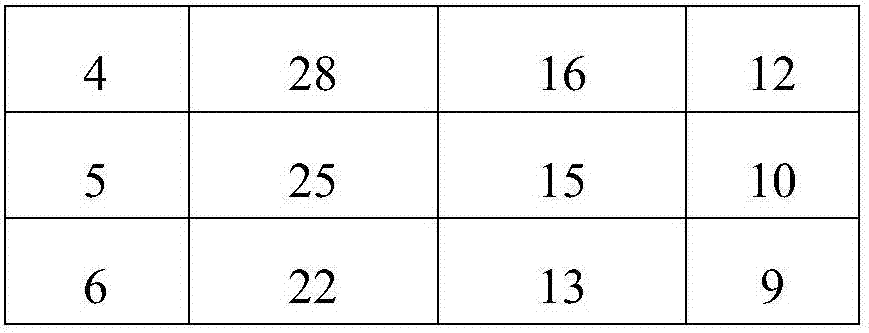

[0031] This embodiment 1 mainly reflects: (1) the preparation method of the water-based drilling fluid of the present embodiment; (2) the environmental protection evaluation of the water-based drilling fluid of the present embodiment; (3) the basic performance parameters of the water-based drilling fluid of the present embodiment (rheological parameters and fluid loss); (4) shale and the variation of expansion after the contact of the water-based drilling fluid of the present embodiment; (5) the lubricating performance of the water-based drilling fluid of the present embodiment; (6) the water-based drilling fluid of the present embodiment Examples Water Activity of Water-Based Drilling Fluids.

[0032] This example 1 provides a kind of water-based drilling fluid, calculated based on the amount added per 100mL of water, the mass parts of the above components are respectively: 1.5g of sodium bentonite, 1.5g of attapulgite, 0.6g of pure-bore, pure-bore-lv0.3g, carboxymethylcellul...

Embodiment 2

[0078] This embodiment 2 mainly reflects: (1) the environmental protection evaluation of the water-based drilling fluid in this embodiment; (2) the rheological parameters (apparent viscosity and plastic viscosity) changes of the water-based drilling fluid in this embodiment under high temperature and high pressure conditions Situation; (3) fluid loss performance analysis of the present embodiment water-based drilling fluid under high temperature and high pressure conditions;

[0079] This Example 2 provides a water-based drilling fluid, calculated based on the amount added per 100mL of water, the mass parts of the above components are: 1.5g of sodium bentonite, 1.5g of attapulgite, and 0.7g of pure-bore , pure-bore-lv0.4g, carboxymethylcellulose 0.25g, lignite resin 2.3g, sodium chloride 4g, sodium carbonate 0.23g.

[0080] Experimental equipment: GJD-B12K frequency conversion high-speed mixer.

[0081] Its preparation method is as follows:

[0082] (1) Firstly, according to...

Embodiment 3

[0115] This embodiment 3 mainly reflects: 1) the environmental protection evaluation of the water-based drilling fluid of this embodiment; (2) the change of rheological parameters (apparent viscosity and plastic viscosity) of the water-based drilling fluid of this embodiment under high temperature and high pressure conditions (3) The fluid loss performance analysis of the present embodiment water-based drilling fluid under high temperature and high pressure conditions;

[0116] This Example 3 provides a water-based drilling fluid, calculated based on the amount added per 100mL of water, the mass parts of the above components are: 1.5g of sodium bentonite, 1.5g of attapulgite, and 0.65g of pure-bore , pure-bore-lv0.35g, carboxymethylcellulose 0.23g, lignite resin 2.32g, sodium chloride 4g, sodium carbonate 0.21g.

[0117] Experimental equipment: GJD-B12K frequency conversion high-speed mixer.

[0118] Its preparation method is as follows:

[0119] (1) Firstly, according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com