Preparation method for rolling liquid

A technology of rolling fluid and preparation steps, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of stratification during storage, poor stability of the rolling fluid, etc. The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

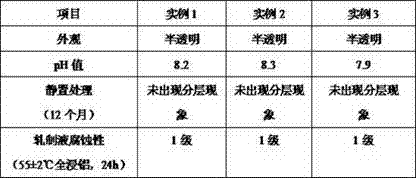

Examples

example 1

[0022] In terms of parts by weight, respectively select 80 parts of boric acid, 100 parts of cetyl alcohol and 120 parts of benzene and add them to a three-necked flask, put the three-necked flask into an oil bath and heat up to 130 ° C, keep stirring for 3 hours to obtain a mixed solution, and add to the mixed solution Add 10% ethanolamine to the mixed solution, continue to stir and react for 4 hours, and discharge the material after the reaction is completed to obtain the reaction product. The reaction product is rotary evaporated at 60°C for 3 hours, and the reaction solution is obtained after evaporation; weigh according to the preparation 1:1 Nano-copper powder and nano-zinc oxide are mixed to obtain a mixed nano-powder. The mixed nano-powder is added to deionized water at a mass ratio of 1:60, and ultrasonically dispersed for 20 minutes under the condition of 30KHz to obtain a dispersion. The reaction solution with a liquid mass of 60% was heated to 80°C, stirred and mixe...

example 2

[0024] In terms of parts by weight, respectively select 60 parts of boric acid, 80 parts of cetyl alcohol and 100 parts of benzene and add them to a three-necked flask, put the three-necked flask into an oil bath and heat up to 120°C, keep stirring for 2 hours to obtain a mixed solution, and add to the mixed solution Add 8% ethanolamine to the mixed solution, continue to stir and react for 3 hours, and discharge the material after the reaction is completed to obtain the reaction product. The reaction product is rotary evaporated at 50°C for 2 hours, and the reaction solution is obtained after evaporation; weigh according to the preparation 1:1 Nano-copper powder and nano-zinc oxide are mixed to obtain a mixed nano-powder. The mixed nano-powder is added to deionized water at a mass ratio of 1:60, and ultrasonically dispersed for 15 minutes under the condition of 20KHz to obtain a dispersion. The reaction solution with a liquid mass of 40% was heated to 60°C, stirred and mixed at...

example 3

[0026]In terms of parts by weight, respectively select 70 parts of boric acid, 90 parts of cetyl alcohol and 110 parts of benzene and add them to a three-necked flask, put the three-necked flask into an oil bath and heat up to 125 ° C, keep stirring for 2 hours to obtain a mixed solution, and add to the mixed solution Add 9% ethanolamine to the mixed solution, continue to stir and react for 4 hours, and discharge the material after the reaction is completed to obtain the reaction product. The reaction product is rotary evaporated at 55°C for 2 hours, and the reaction solution is obtained after evaporation; weigh according to the preparation 1:1 Nano-copper powder and nano-zinc oxide are mixed to obtain mixed nano-powder. Add the mixed nano-powder to deionized water according to the mass ratio of 1:60, and ultrasonically disperse it under the condition of 25KHz for 17 minutes to obtain a dispersion liquid. Add dispersing liquid to the dispersion liquid The liquid mass is 50% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com