A method for reducing the interaction between inductive motor loads and drives

A driver, inductive technology, applied in the direction of AC motor control, electrical components, control systems, etc., can solve the problems of reduced motor reliability, lack, poor high-frequency impedance characteristics, etc., to achieve small mutual influence, good response effect, reduce Effects of switching transients and adverse effects of motor loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

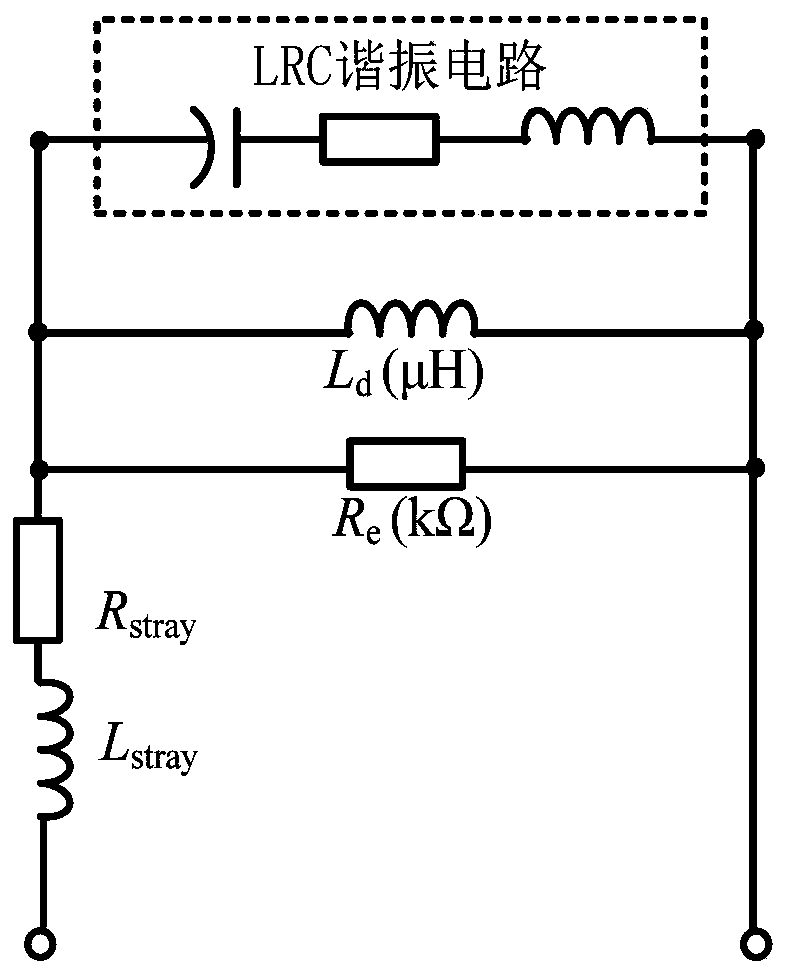

[0027] Such as figure 1 The high-frequency equivalent circuit of the induction motor including connecting cables is shown, and the impedance characteristics generated by the parasitic parameters such as the skin effect and the interturn capacitance of the stator winding in the induction motor are equivalent through the LRC resonant circuit. Will represent the equivalent resistance R of the core loss caused by eddy current at high frequency e and stator winding inductance L d Connected in parallel next to the LRC resonant circuit, the stray resistance R of the line stray and inductance L stray connected in series in a parallel circuit.

[0028] The way to actually use this equivalent circuit model is:

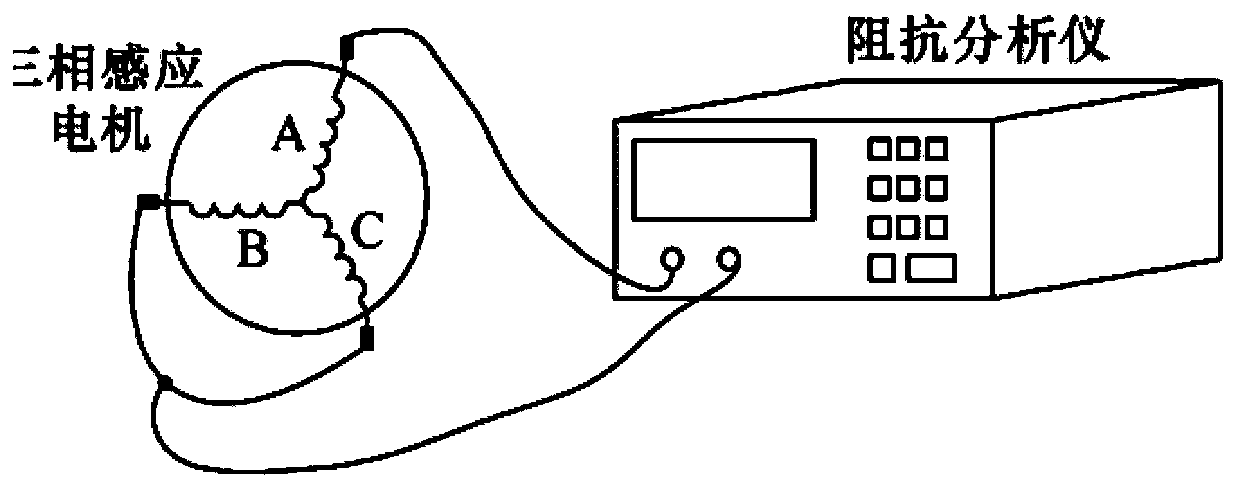

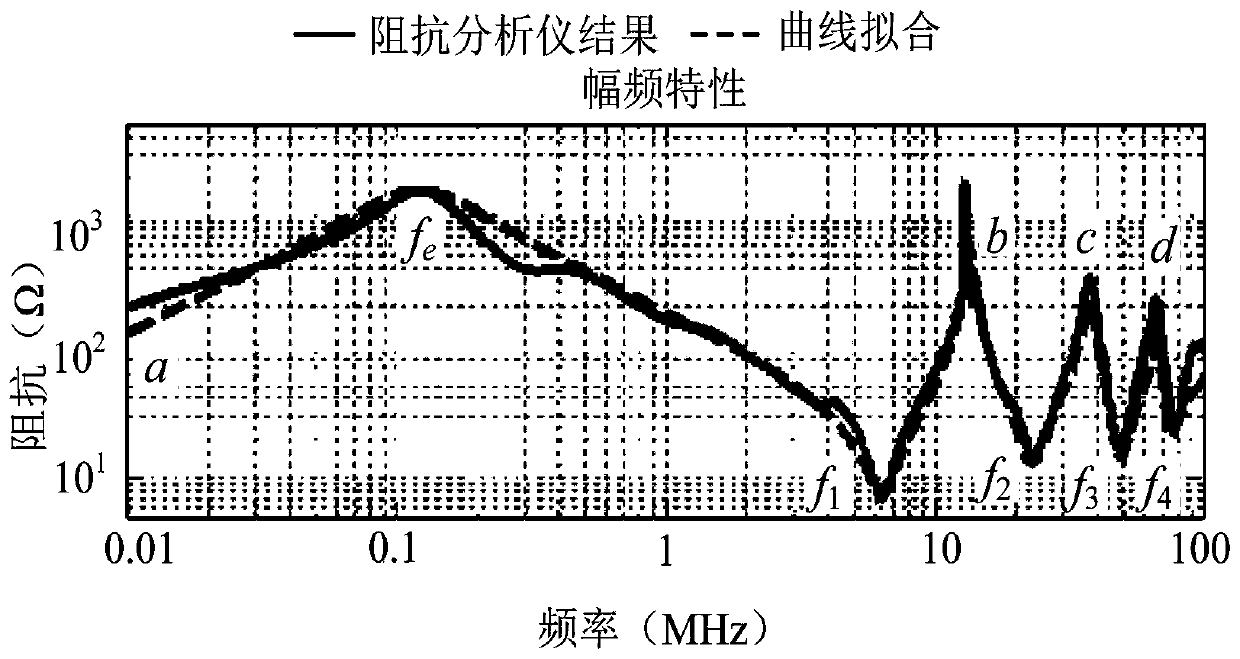

[0029] Step 1——Agilent 4294A impedance analyzer 20 is used to measure the impedance of an induction motor 10 with a connection cable of 2 m and a power of 7.5 kW. The connection schematic diagram is as follows figure 2 shown. When performing impedance measurement: one pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com