Automatic chamfer milling equipment

A milling and chamfering, automatic technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment and other directions, can solve problems such as increased workload of workers, workpiece pits or burrs, insufficient process accuracy, etc., to achieve continuous consistency improvement, The effect of improving workpiece quality and speeding up production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

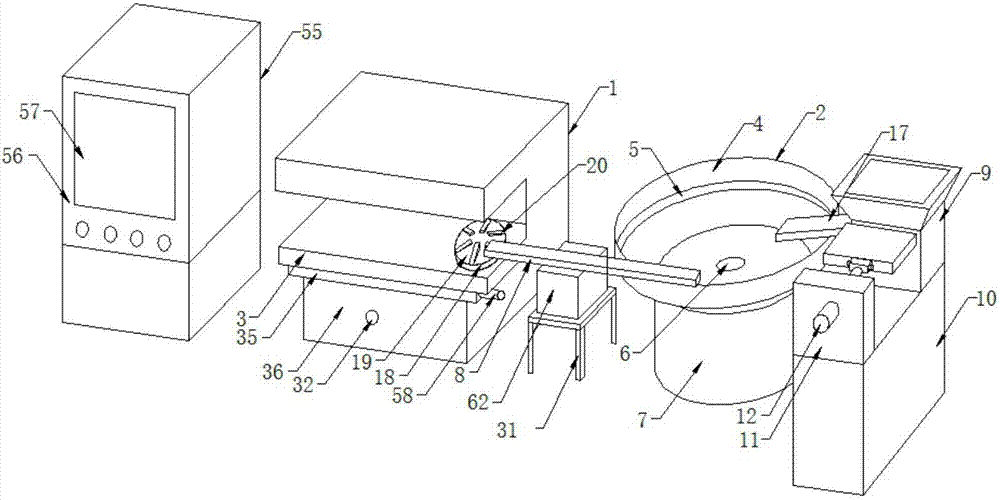

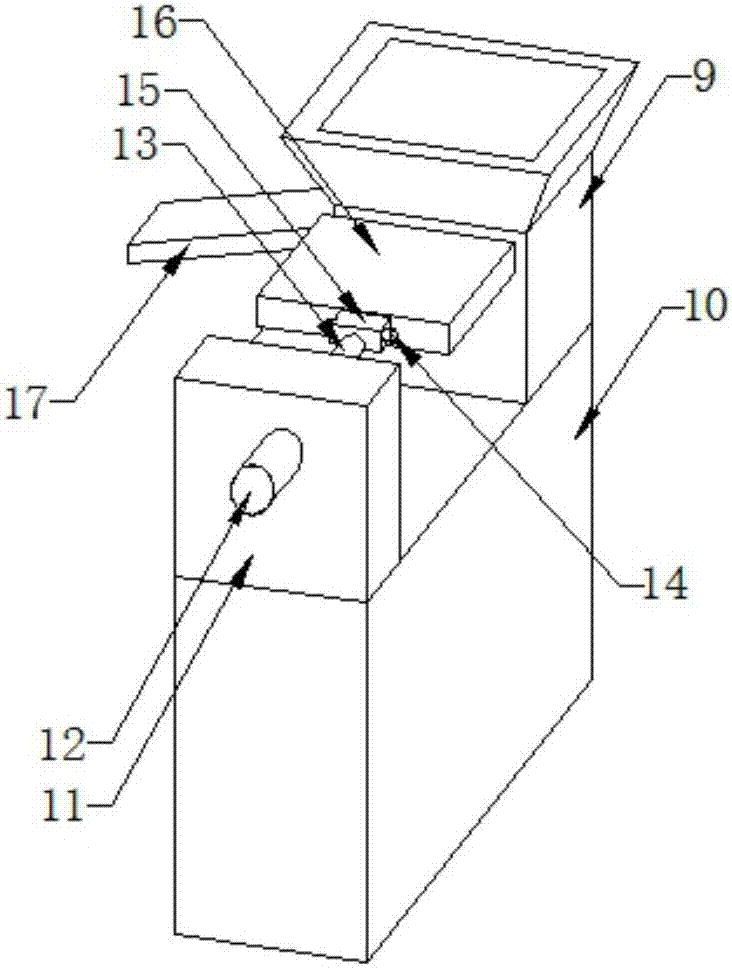

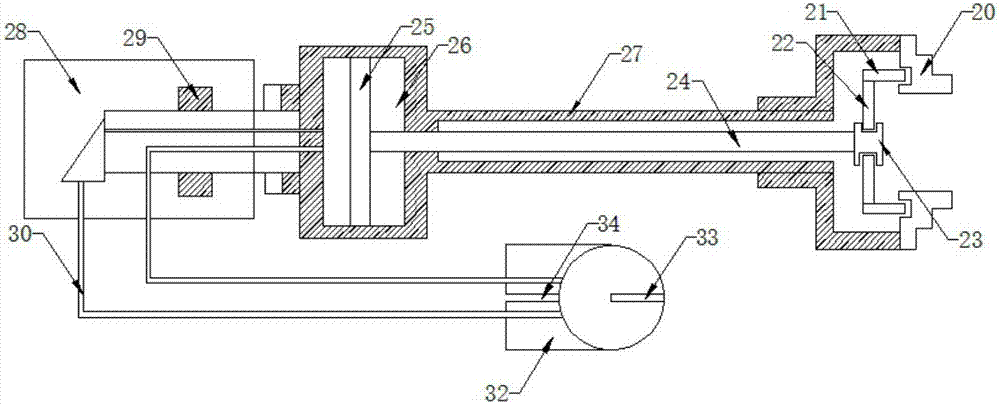

[0022] Such as Figure 1-5As shown, the present invention provides an automatic milling and chamfering equipment, including an automatic milling and chamfering machine tool 1 and a vibrating feeding tray 2. The top plate 4, the top plate 4 is provided with a directional rail 5, the center of the directional rail 5 is provided with a bearing 6, the bottom of the top plate 4 is provided with a chassis 7, the chassis 7 is driven by an electromagnet, and one end of the directional rail 5 is connected There is a linear feeder 8 and the linear feeder 8 leads to the workbench 3 of the automatic milling and chamfering machine tool 1. One side of the vibrating feeding tray 2 is provided with a feeder 9, and the bottom of the feeder 9 is provided with a fixed seat 10. One end of seat 10 top is fixed with fixed plate 11, and fixed plate 11 is provided with the hydraulic driver 12 that runs through fixed plate 11 transversely, and one end of hydraulic driver 12 is connected with telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com