Pretreatment system and treatment method for permeate before entering the regulating tank in solid waste treatment plant

A permeate and pretreatment technology, applied in filtration treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor treatment effect, influence of treatment process, low treatment efficiency, etc., so as to improve the effect and improve the treatment efficiency. effect, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

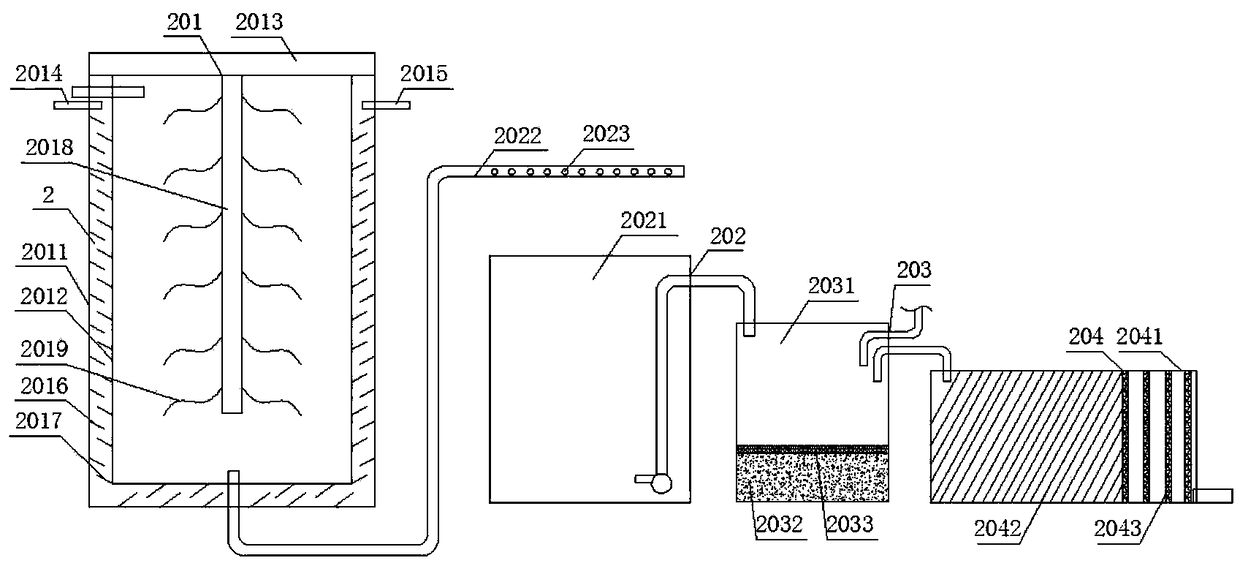

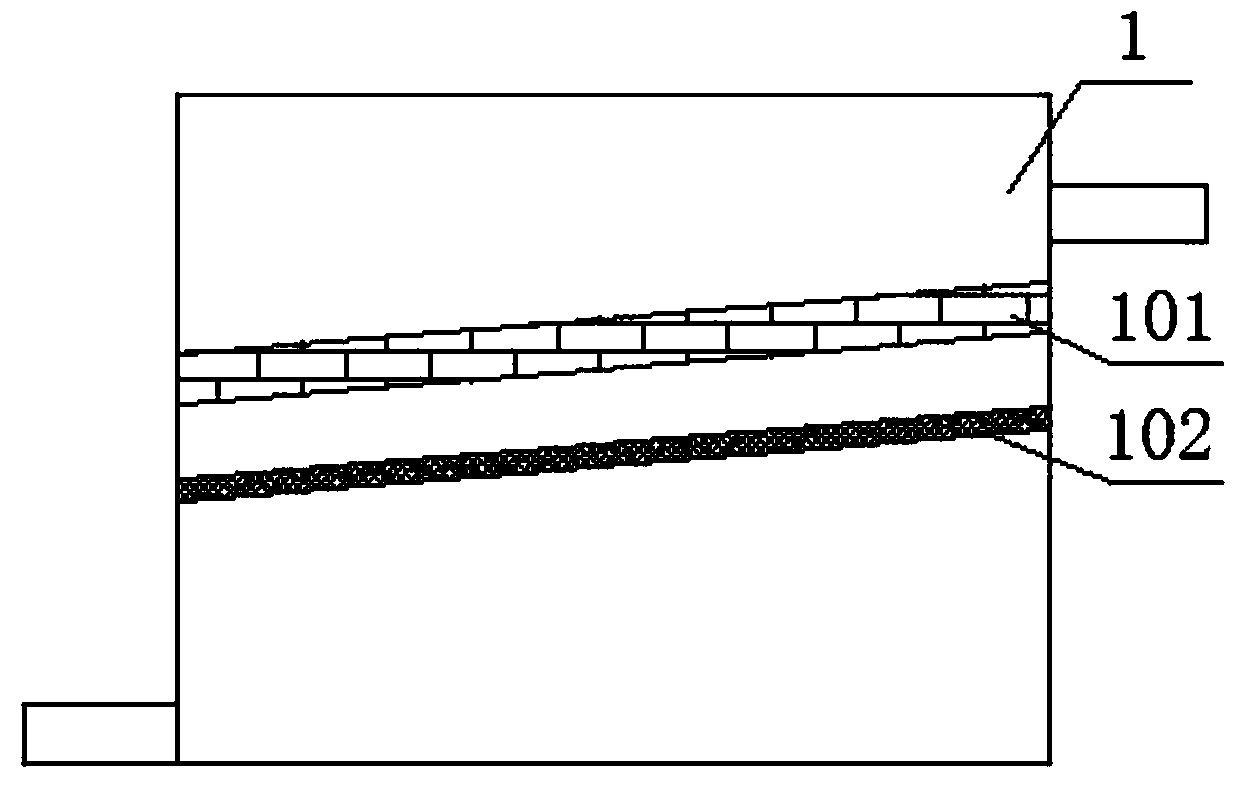

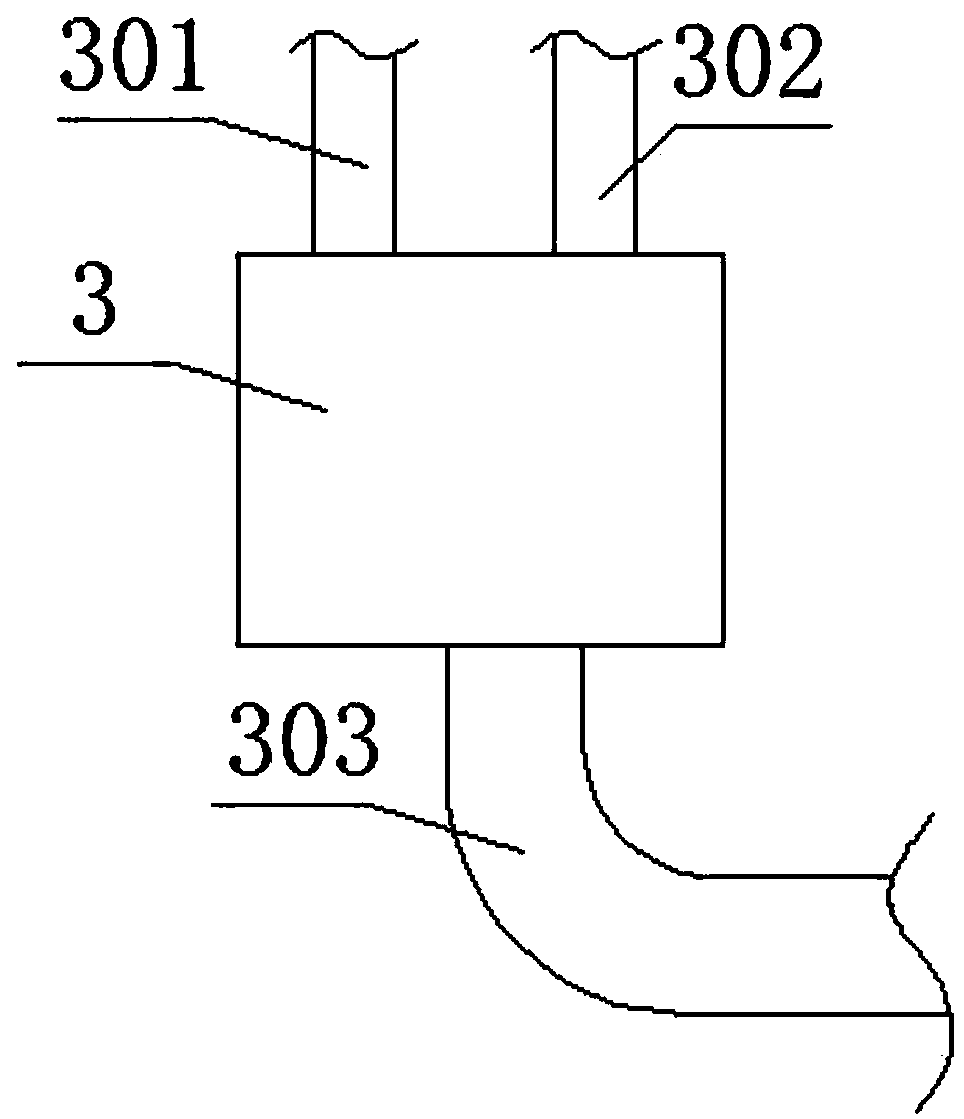

[0022]As shown in the figure, a pretreatment system for the permeate in a solid waste treatment plant before entering the regulating tank, including a solid impurity filter tank 1 and a flocculation and sedimentation device 2, is characterized in that: the solid impurity filter tank 1 passes through a mixer 3 Connected with the flocculation and sedimentation device 2, the mixer 3 is provided with a raw water inlet pipe 301, a treated water inlet pipe 302 and a mixing outlet pipe 303, the raw water inlet pipe 301 is connected to the outlet of the solid impurity filter tank 1, and the flocculation The sedimentation device 2 includes a flocculation mechanism 201, a cooling mechanism 202, a sedimentation mechanism 203, and a micro floc capture mechanism 204 connected in sequence, and the flocculation mechanism 201 includes an outer flocculation cylinder 2011, an inner flocculation cylinder arranged in the outer flocculation cylinder 2011 2012 and the cylinder cover 2013 covering th...

Embodiment 2

[0030] As shown in the figure, a pretreatment system for the permeate in a solid waste treatment plant before entering the regulating tank, including a solid impurity filter tank 1 and a flocculation and sedimentation device 2, is characterized in that: the solid impurity filter tank 1 passes through a mixer 3 Connected with the flocculation and sedimentation device 2, the mixer 3 is provided with a raw water inlet pipe 301, a treated water inlet pipe 302 and a mixing outlet pipe 303, the raw water inlet pipe 301 is connected to the outlet of the solid impurity filter tank 1, and the flocculation The sedimentation device 2 includes a flocculation mechanism 201, a cooling mechanism 202, a sedimentation mechanism 203, and a micro floc capture mechanism 204 connected in sequence, and the flocculation mechanism 201 includes an outer flocculation cylinder 2011, an inner flocculation cylinder arranged in the outer flocculation cylinder 2011 2012 and the cylinder cover 2013 covering t...

Embodiment 3

[0038]As shown in the figure, a pretreatment system for the permeate in a solid waste treatment plant before entering the regulating tank, including a solid impurity filter tank 1 and a flocculation and sedimentation device 2, is characterized in that: the solid impurity filter tank 1 passes through a mixer 3 Connected with the flocculation and sedimentation device 2, the mixer 3 is provided with a raw water inlet pipe 301, a treated water inlet pipe 302 and a mixing outlet pipe 303, the raw water inlet pipe 301 is connected to the outlet of the solid impurity filter tank 1, and the flocculation The sedimentation device 2 includes a flocculation mechanism 201, a cooling mechanism 202, a sedimentation mechanism 203, and a micro floc capture mechanism 204 connected in sequence, and the flocculation mechanism 201 includes an outer flocculation cylinder 2011, an inner flocculation cylinder arranged in the outer flocculation cylinder 2011 2012 and the cylinder cover 2013 covering th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com