Clamp for near net shaping of ceramic matrix composite material turbine guide vane of aeroengine

A turbine guider and aero-engine technology, which is applied in the field of aero-engine parts manufacturing, can solve the problems of ceramic matrix composite material turbine guider blade preparation failure, difficulty in ensuring the shape and size of ceramic matrix composite material blades, and protrusions, etc., to achieve improved Effects on preparation quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

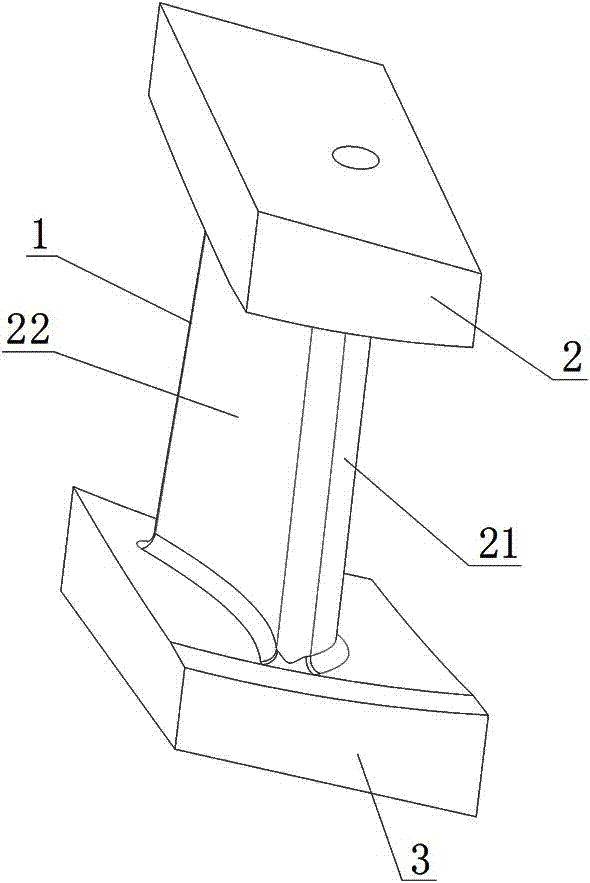

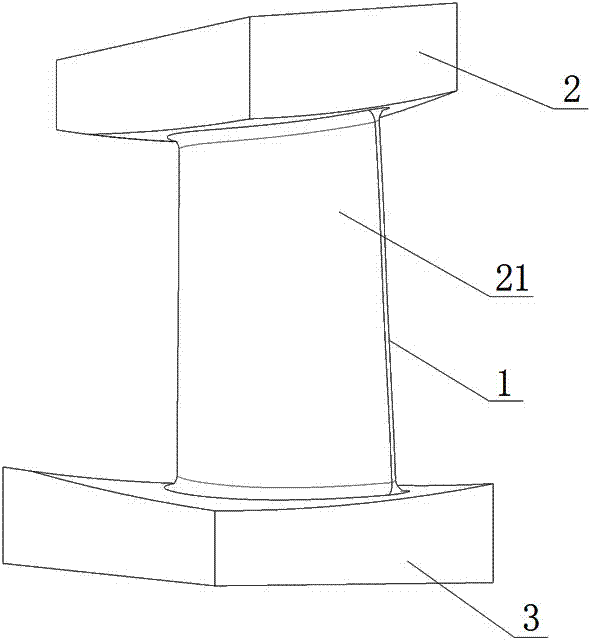

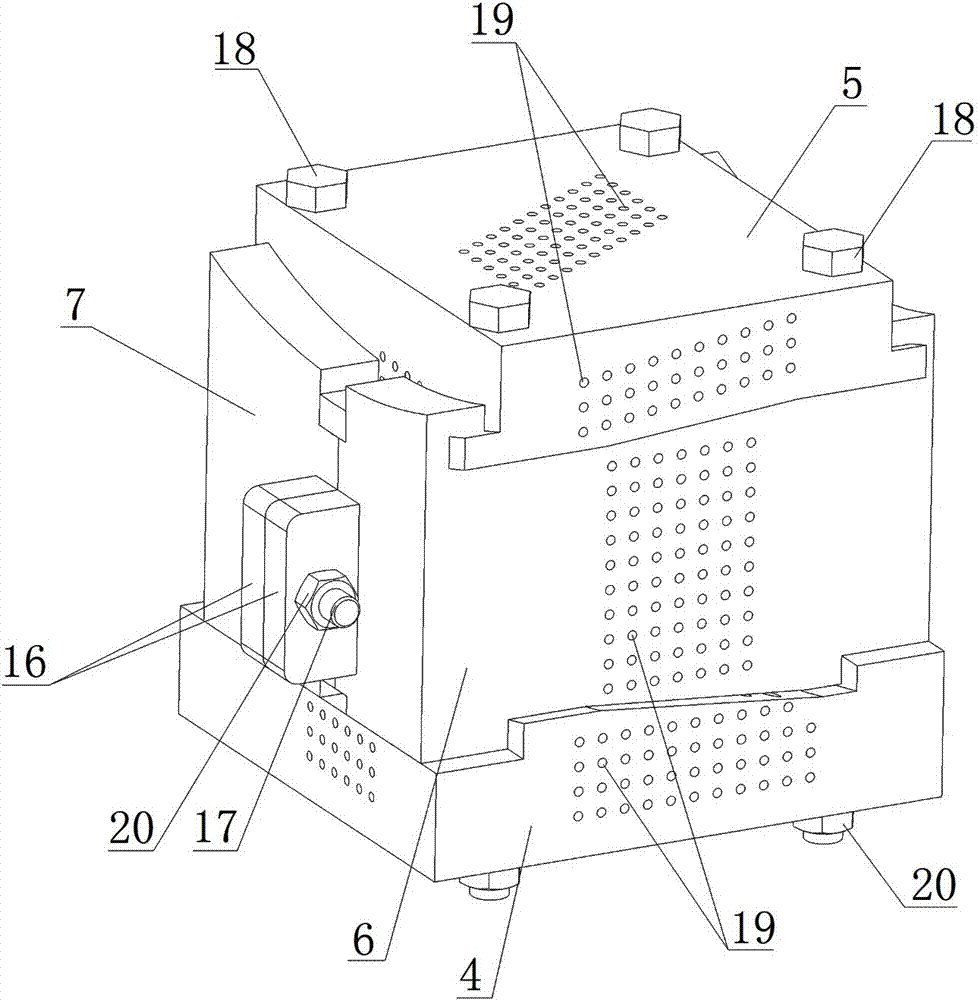

[0024] Such as Figure 3~11 Shown, a kind of fixture for near-net shape of turbine guider blade of aeroengine ceramic matrix composite material, it comprises large edge plate module 4, small edge plate module 5, blade back airfoil module 6 and blade pot airfoil module 7, so The top of the large edge plate module 4 is provided with a cavity A8 that matches the large edge plate 3 of the blade prefabricated body. The large edge plate module 4 is also provided with a blade back positioning block 9 and a blade back positioning block respectively located on the left and right sides of the cavity A8. The pot positioning block 10, the leaf back positioning block 9 is located on the front side of the leaf pot positioning block 10, the bottom of the small edge plate module 5 is provided with a cavity B11 match...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com