A fully synthetic metal cutting fluid

A metal cutting fluid, full synthesis technology, applied in lubricating compositions, petroleum industry and other directions, can solve the problems of not complying with green environmental protection, cumbersome preparation process, cumbersome synthesis method, etc., achieving simple manufacturing process, abundant sources, and cheap raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

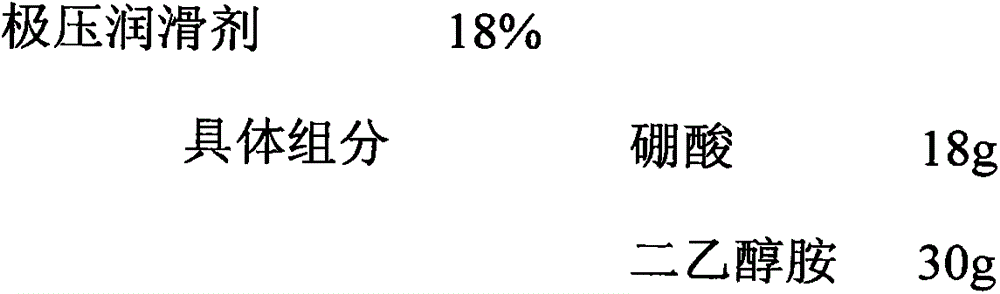

Embodiment 1

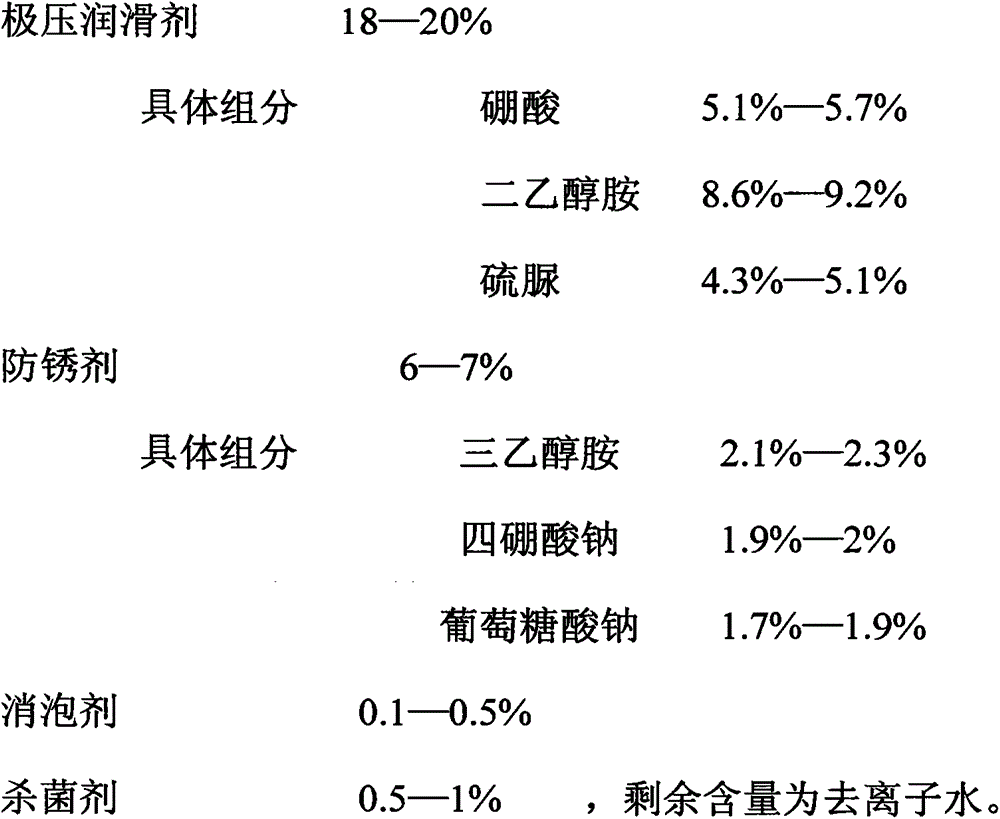

[0025] A fully synthetic metal cutting fluid, the components of which are by mass percentage:

[0026]

[0027]

[0028] The preparation method of the fully synthetic metal cutting fluid comprises the following steps:

[0029] (1) Synthesis method of extreme pressure lubricant

[0030] Put 18g of boric acid and 30g of diethanolamine in a 250ml round bottom flask, put it in a magnetic stirring oil bath, install a condensation device to ensure the sealing of the device, and react at 140°C. After 1h, when anhydrous is formed, add 11g Thiourea, continue to react for 1 hour, stop the reaction; after cooling, a yellow-green viscous solution is obtained; add an appropriate amount of hot water to dissolve the product, and transfer the product.

[0031] (2) Preparation of antirust agent: Take 7.5g of triethanolamine, 6.5g of sodium tetraborate, and 6.0g of sodium gluconate, put them into a beaker with an appropriate amount of water, stir them mechanically to make them evenly dis...

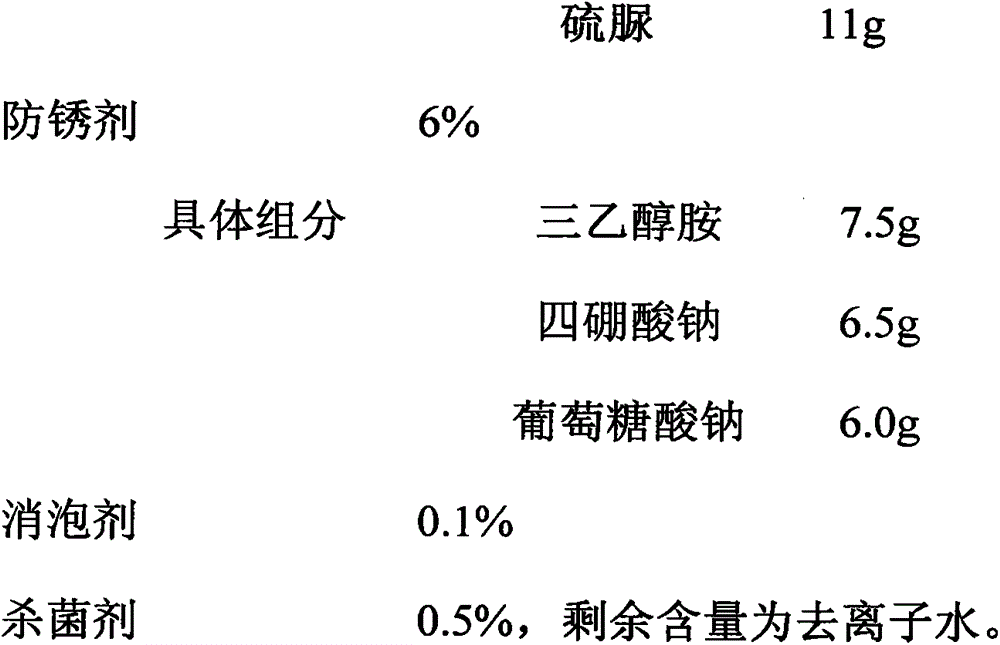

Embodiment 2

[0034] A fully synthetic metal cutting fluid, the components of which are by mass percentage:

[0035]

[0036] The preparation method of the fully synthetic metal cutting fluid comprises the following steps:

[0037] (1) Synthesis method of extreme pressure lubricant

[0038] Put 19g of boric acid and 31g of diethanolamine in a 250ml round-bottomed flask, put them in a magnetic stirring oil bath, install a condensation device to ensure the sealing of the device, react at 140°C, and after 1h, when anhydrous is formed, add 17g Thiourea, continue to react for 1 hour, stop the reaction; after cooling, a yellow-green viscous solution is obtained; add an appropriate amount of hot water to dissolve the product, and transfer the product.

[0039] (2) Preparation of antirust agent: Take 8g of triethanolamine, 7g of sodium tetraborate, and 6.5g of sodium gluconate, put them into a beaker with an appropriate amount of water, stir them mechanically to make them evenly dissolve in wat...

Embodiment 3

[0042] A fully synthetic metal cutting fluid, the components of which are by mass percentage:

[0043]

[0044] The preparation method of the fully synthetic metal cutting fluid comprises the following steps:

[0045] (1) Synthesis method of extreme pressure lubricant

[0046] Put 20g of boric acid and 32g of diethanolamine in a 250ml round bottom flask, put it in a magnetic stirring oil bath, install a condensation device to ensure the sealing of the device, and react at 140°C. After 1h, when anhydrous is formed, add 30g Thiourea, continue to react for 1 hour, stop the reaction; after cooling, a yellow-green viscous solution is obtained; add an appropriate amount of hot water to dissolve the product, and transfer the product.

[0047] (2) Preparation of antirust agent: Take 8g of triethanolamine, 7g of sodium tetraborate, and 6.5g of sodium gluconate, put them into a beaker with an appropriate amount of water, stir them mechanically to make them evenly dissolve in water, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com