Solid-solution method of stainless steel bent pipe fitting and device thereof

A technology for stainless steel and pipe bending, which is applied in the field of solid solution method and device of stainless steel pipe bending pipe fittings, can solve problems such as deformation of bending parts, and achieve the effect of ensuring the bending angle, not easy to deform, and the size of the pipe fittings is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

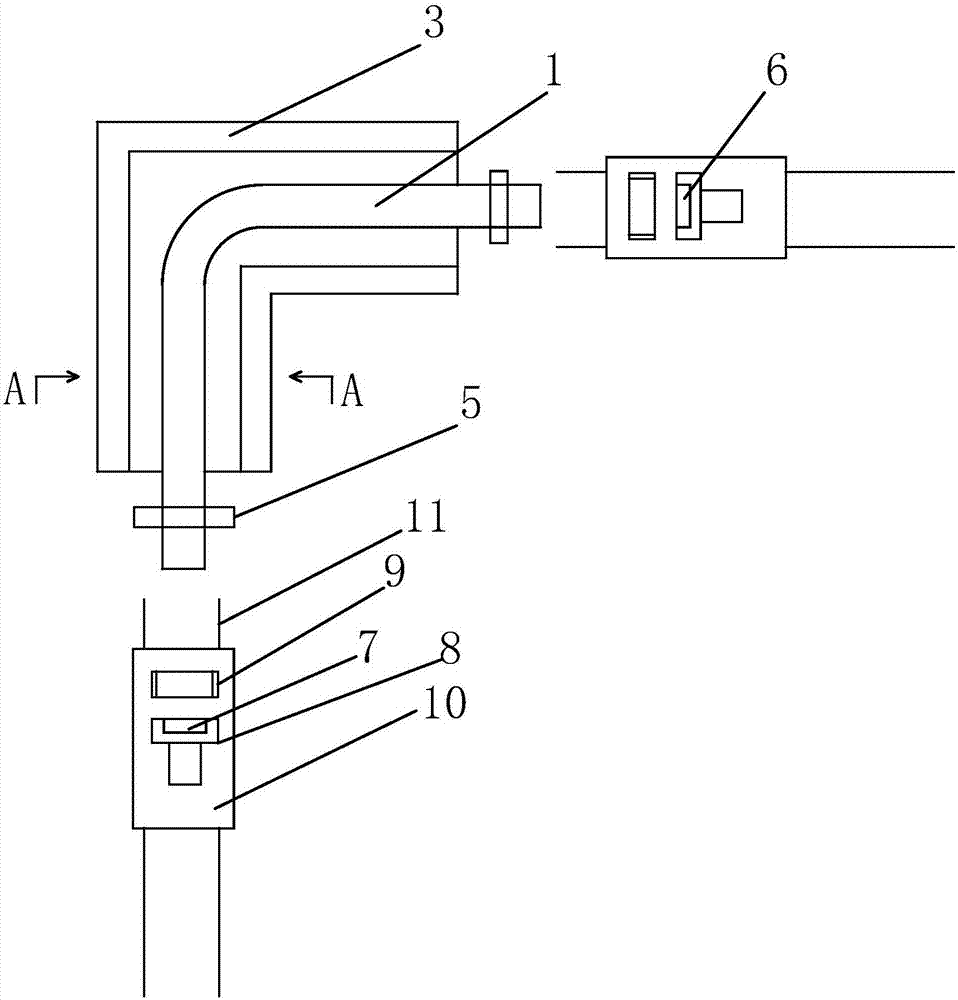

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0025] Example. A solid solution method for stainless steel elbow fittings, comprising the following steps:

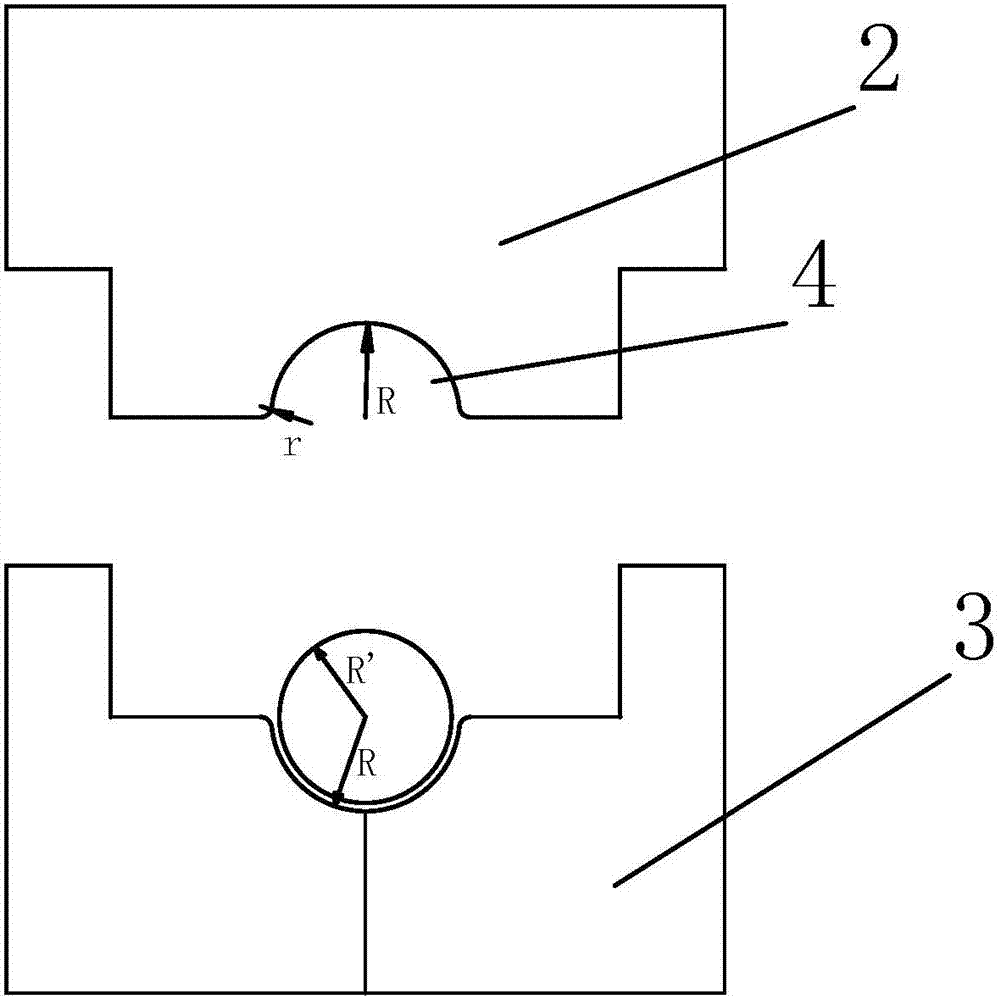

[0026] ①Clamp the bend of the stainless steel elbow in the circular channel enclosed by the upper and lower molds (corundum mullite castings), and the circular shape matches the stainless steel elbow;

[0027] ②Connect electrodes at both ends of the stainless steel elbow and pipe fittings, and use high-frequency voltage to heat the stainless steel elbow and pipe fittings to the solution temperature for full solution;

[0028] ③ Cut off the high-frequency voltage output, connect the water injection pipe at one end of the stainless steel elbow fitting, and inject cooling water into the stainless steel elbow fitting to keep the cooling water flowing at a speed of 1.2-1.8m / s in the stainless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com