Automatic continuous foaming formation type production technology process

A production process and automatic technology, applied in the field of material processing, can solve problems such as low thermal conductivity of impact resistance, uneven internal bubbles, and affecting product quality, so as to improve performance stability, reduce energy consumption, and shorten production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0046] Refer to the attached Figure 1-2 An automatic continuous foam molding production process flow in Embodiment 1 of the present invention is described.

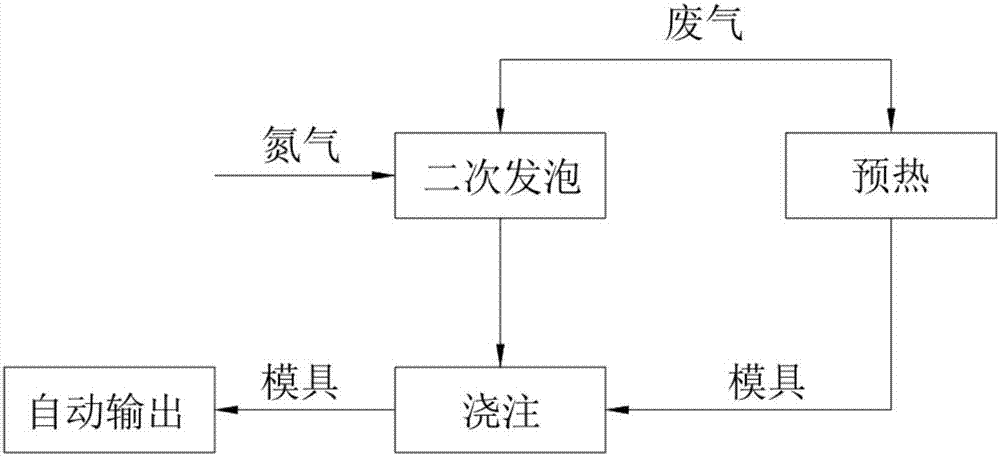

[0047] Such as figure 1 and figure 2 Shown, a kind of automated continuous foam molding production process, is characterized in that, comprises the following steps:

[0048] a. The molten aluminum transfer part is quantitatively transferred to the foaming chamber 31 after the primary foaming; the temperature of the molten aluminum after the primary foaming is 800-950°C;...

Embodiment 2

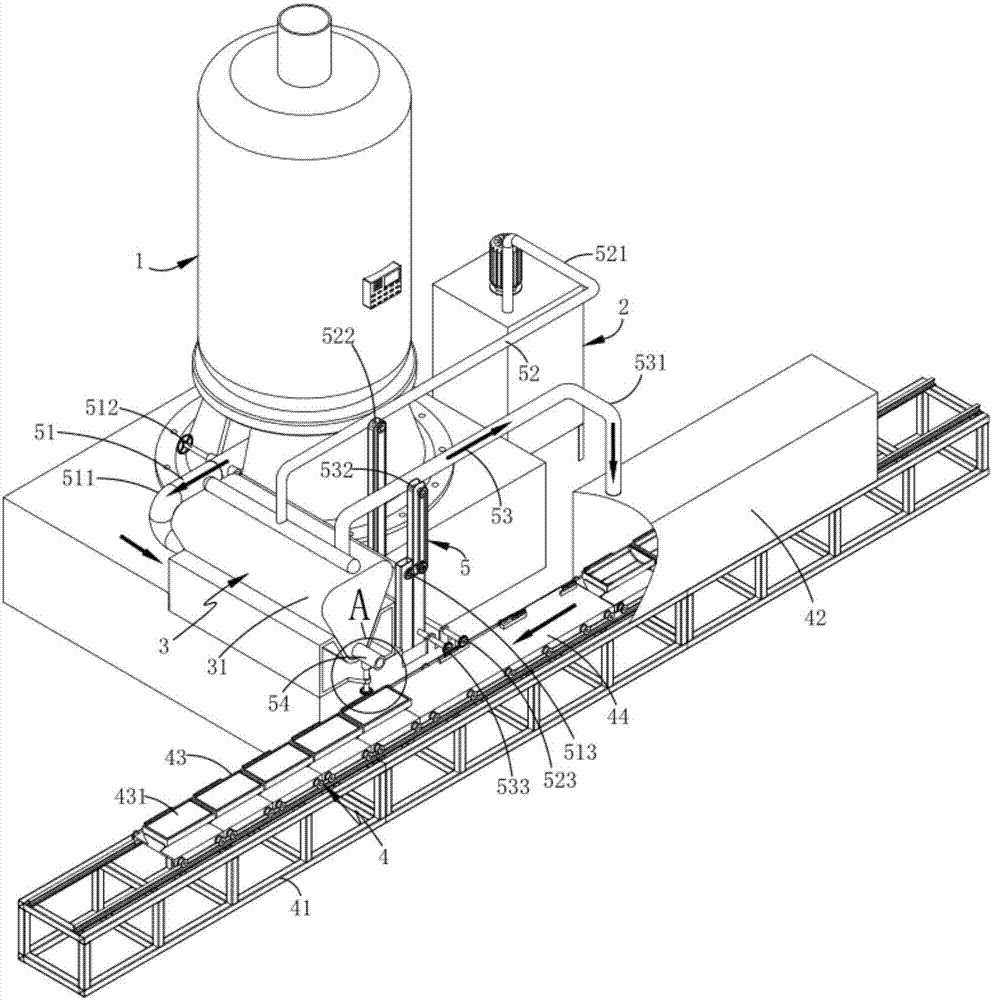

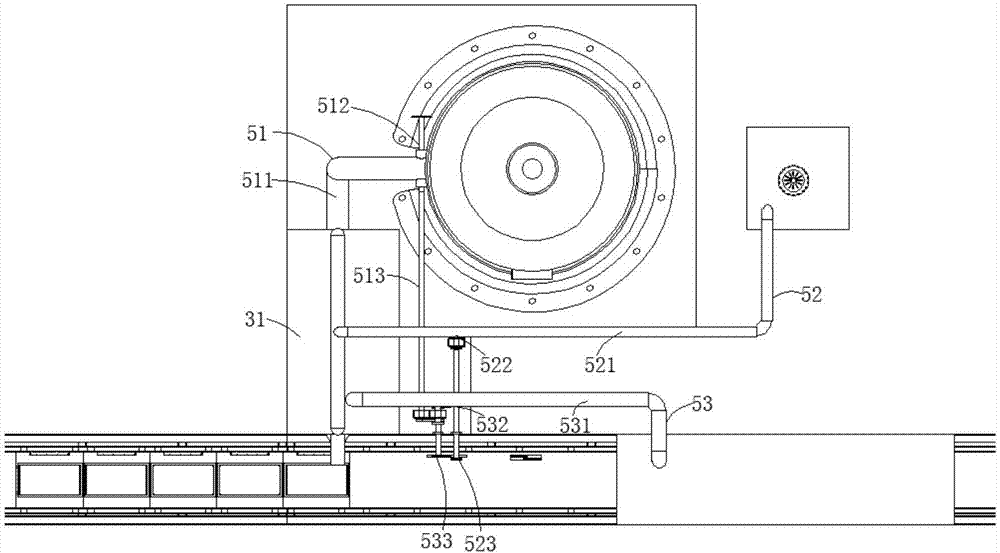

[0069] Reference attached Figure 2-13 An automatic production control system for foamed aluminum according to Embodiment 2 of the present invention is described.

[0070] Such as figure 2 As shown, the present invention also discloses a foamed aluminum automatic production control system, including a foaming holding furnace 1, a nitrogen supply assembly 2, and also includes:

[0071] Secondary foaming mechanism 3, said secondary foaming mechanism 3 includes a foaming chamber 31 for caching aluminum liquid that can be poured by a plurality of mold groups 43, the foaming chamber 31 is connected with foaming holding furnace 1, nitrogen The supply components 2 are connected; the aluminum liquid flows into the secondary foaming mechanism 3 intermittently through the foaming holding furnace 1, and after the aluminum liquid flows in, the nitrogen supply component 2 introduces foaming gas into the aluminum liquid for secondary foaming.

[0072] A conveying mechanism 4, which is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com