Iron-based soft-magnetic amorphous steel and application thereof

An amorphous steel and soft magnetic technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of low mechanical and magnetic properties, inability to meet high magnetic properties, and limit industrial applications, so as to reduce the process, Reduced thermal stability and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

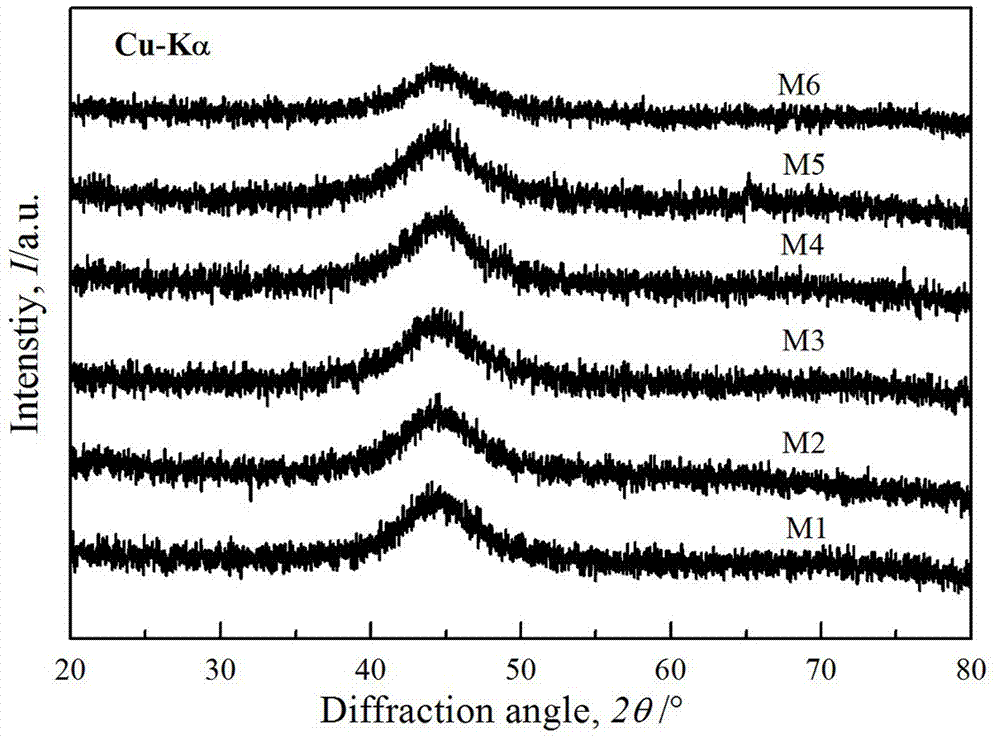

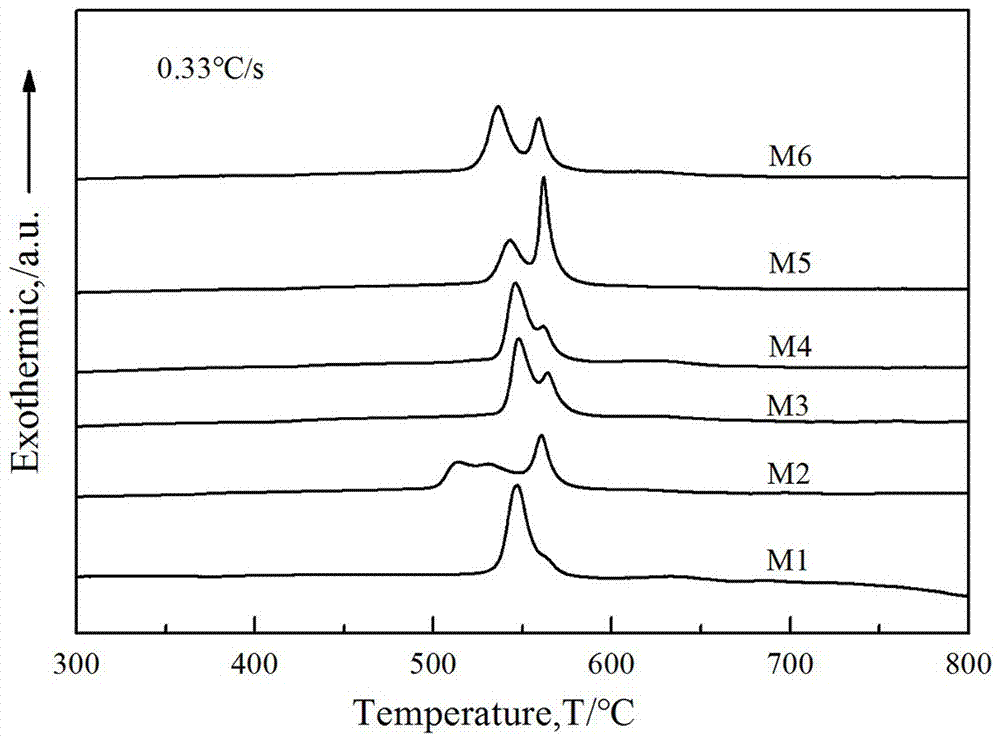

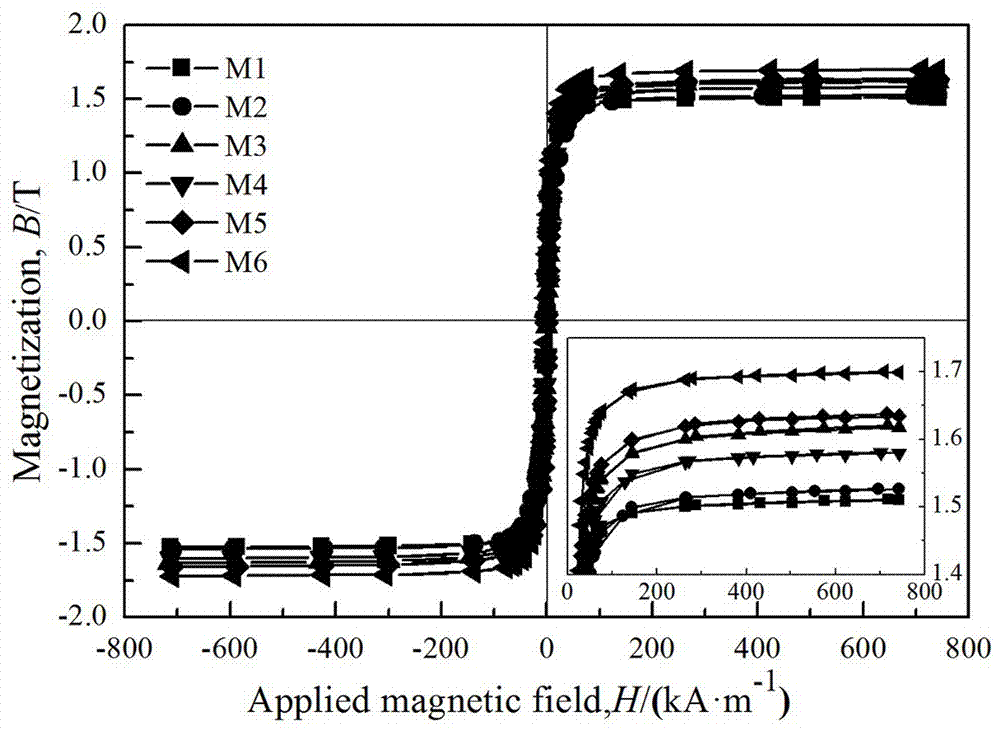

[0039] Embodiment 1 A kind of iron base soft magnetic amorphous steel Fe 75.15 C 0.04 Si 9.9 mn 0.20 P 0.11 S 0.02 Cr 1.49 Al 0.05 Ni 0.94 B 12.10 (at%), denoted as M1. Its preparation method comprises the following steps:

[0040] 1) Ingredients: low alloy steel Fe 95.57 C 0.05 Si 0.81 mn 0.26 P 0.14 S 0.02 Cr 1.9 Al 0.06 Ni 1.19 (at%), Si (99.999wt%), FeB (B content 19.62 wt%), FeP (P content 24.98 wt%), FeC (C content 5 wt%) were proportioned according to the required element ratio. Among them, alloy steel: FeB: Si= 20.083: 3.556: 1.360.

[0041] 2) Melting the master alloy: Put the prepared master alloy components into the boron nitride crucible, try to put the alloy steel or alloy elements with high density and low melting point on it, and then put it into the induction coil in the vacuum induction melting cavity , and then use a mechanical pump and a diffusion pump to evacuate, when the vacuum reaches 2.0×10 -3 After Pa, it is filled with 0.04MP...

Embodiment 2

[0043] Embodiment 2 A kind of iron base soft magnetic amorphous steel Fe 76.11 C 0.04 Si 9.45 mn 0.21 P 0.11 S 0.02 Cr 1.51 Al 0.05 Ni 0.95 B 11.55 (at%), denoted as M2. Its preparation method comprises the following steps:

[0044] 1) Ingredients: low alloy steel Fe 95.57 C 0.05 Si 0.81 mn 0.26 P 0.14 S 0.02 Cr 1.9 Al 0.06 Ni 1.19 (at%), Si (99.999wt%), FeB (B content 19.62 wt%), FeP (P content 24.98 wt%), FeC (C content 5 wt%) were proportioned according to the required element ratio. Among them, alloy steel: FeB: Si= 20.348: 3.369: 1.283.

[0045] 2) Melting the master alloy: Put the prepared master alloy components into the boron nitride crucible, try to put the alloy steel or alloy elements with high density and low melting point on it, and then put it into the induction coil in the vacuum induction melting cavity , and then use a mechanical pump and a diffusion pump to evacuate, when the vacuum reaches 2.2×10 -3 After Pa, it is filled with 0.04...

Embodiment 3

[0047] Embodiment 3 A kind of iron base soft magnetic amorphous steel Fe 77.64 C 0.04 Si 9.45 mn 0.21 P 0.11 Al 0.05 Ni 0.95 B 11.55 (at%)

[0048] , denoted as M3. Its preparation method comprises the following steps:

[0049] 1) Ingredients: According to the ratio of elements required for master alloy composition design, FeB (B content 19.62wt%), FeP (P content 24.98 wt%), FeC (C content 5 wt%).

[0050] 2) Melting the master alloy: Put the prepared master alloy components into the boron nitride crucible, try to put the alloy steel or alloy elements with high density and low melting point on it, and then put it into the induction coil in the vacuum induction melting cavity , then use a mechanical pump and a diffusion pump to evacuate, when the vacuum reaches 2.4×10 -3 After Pa, it is filled with 0.045 MPa argon gas with a purity of 99.999% as a protective gas. Then start to smelt the master alloy. After one smelting, turn off the power supply, and continue heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com