Stainless steel fiber blended metal garment fabric used for fencing and its preparation process

A fiber blending and preparation technology, which is applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of poor electrical conductivity, poor moisture absorption comfort, and poor softness of the fabric, and achieve soft hand feeling, good hygroscopicity, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

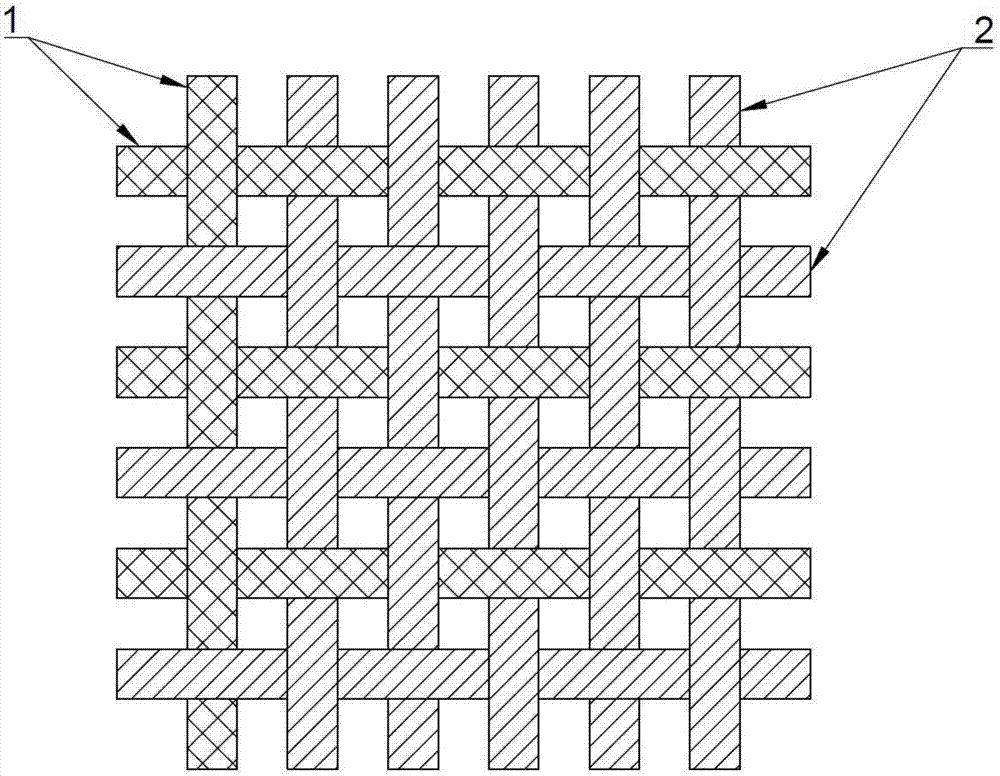

[0032] A stainless steel fiber blended fencing sports metal clothing fabric, the fabric is a plain weave structure formed by combining the blended conductive yarn 1 and the 150D high-strength polyester yarn 2, and the blended conductive yarn 1 is blended with stainless steel fibers and cotton fibers with a diameter of 6.8 μm Made, the content of stainless steel fiber is 15%, and the content of cotton fiber is 85%.

[0033] The fineness of the blended conductive yarn 1 is 29.0tex; the twist of the blended conductive yarn 1 is 205 twists / 10cm.

[0034] The warp direction of the fabric is formed by arranging high-strength polyester yarn 2 and blended conductive yarn 1 in a ratio of 5:1; the weft direction of the fabric is formed by arranging high-strength polyester yarn 2 and blended conductive yarn 1 in a ratio of 1:1.

[0035] The warp density of the fabric is 160 threads / 10cm; the weft density of the fabric is 120 threads / 10cm.

[0036] The preparation process of the fabric c...

Embodiment 2

[0043] Referring to Example 1, the only difference is that the stainless steel fiber and cotton fiber are blended, the contents are 25% and 75% respectively, and the fineness is 29.0tex, and the twist is 205 twists / 10cm blended conductive yarn.

Embodiment 3

[0045] Referring to Example 1, the only difference is that the stainless steel fiber and cotton fiber are blended, the contents are respectively 20% and 80%, and the fineness is 29.0tex, and the twist is 205 twists / 10cm blended conductive yarn.

[0046] The present invention adopts stainless steel short fiber / cotton blended conductive yarn as conductive yarn and high-strength polyester yarn for weaving. Due to the good softness of stainless steel short fiber / cotton blended conductive yarn, the fabric has a soft hand feeling; the hygroscopicity is good, and because the fabric of the present invention Cotton fiber is used in the fabric, which has high hygroscopicity, so the moisture absorption comfort of the fabric is relatively good; the blended conductive yarn of the present invention has good conductivity, which makes the fabric have good conductivity, reduces the possibility of misjudgment, and helps to improve performance .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com