Vacuum-bag-type liquid injection pressurization combined grouting reinforcement super-soft soil foundation treatment method

A foundation treatment and grouting reinforcement technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of unsatisfactory reinforcement treatment effect, accelerated soil consolidation rate, high engineering cost, etc., and achieves the goal of construction method Simple and easy to implement, speed up the reinforcement process, and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

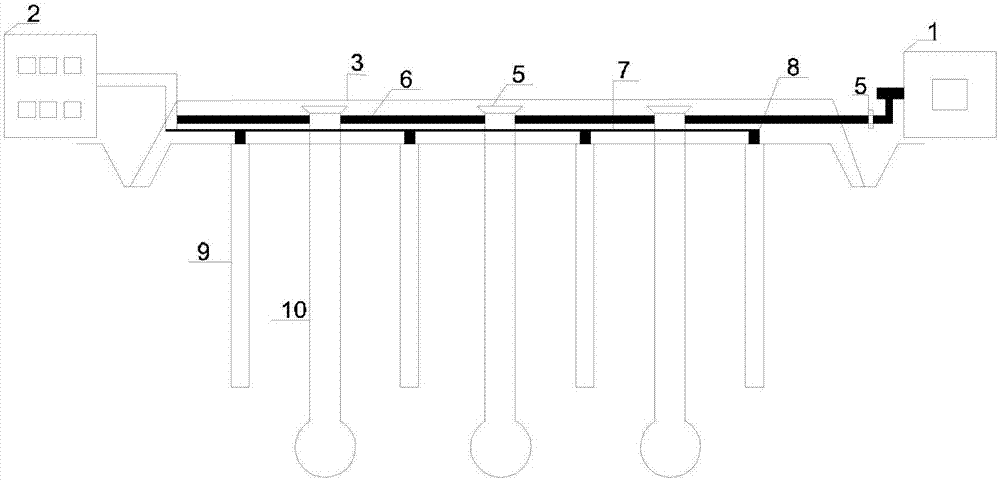

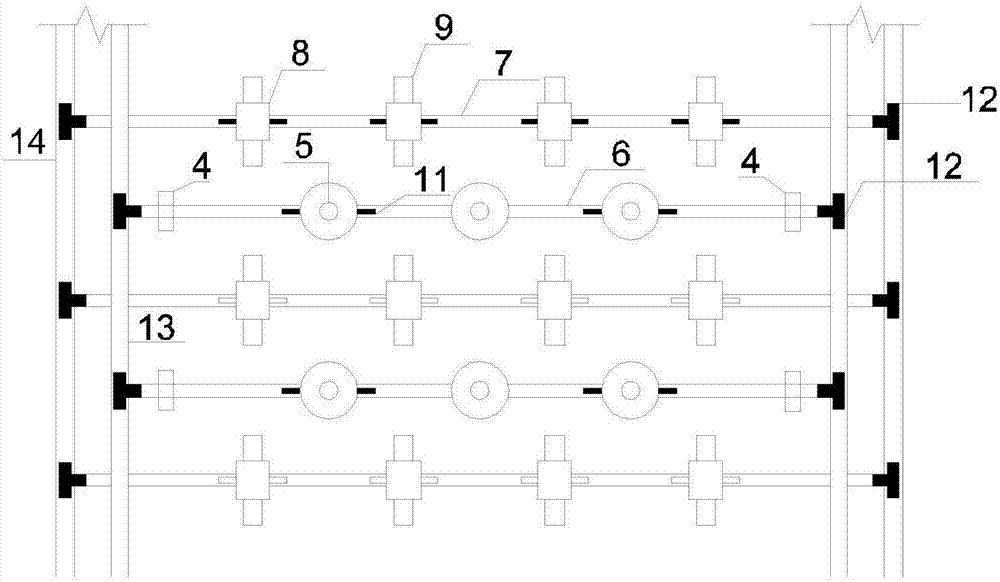

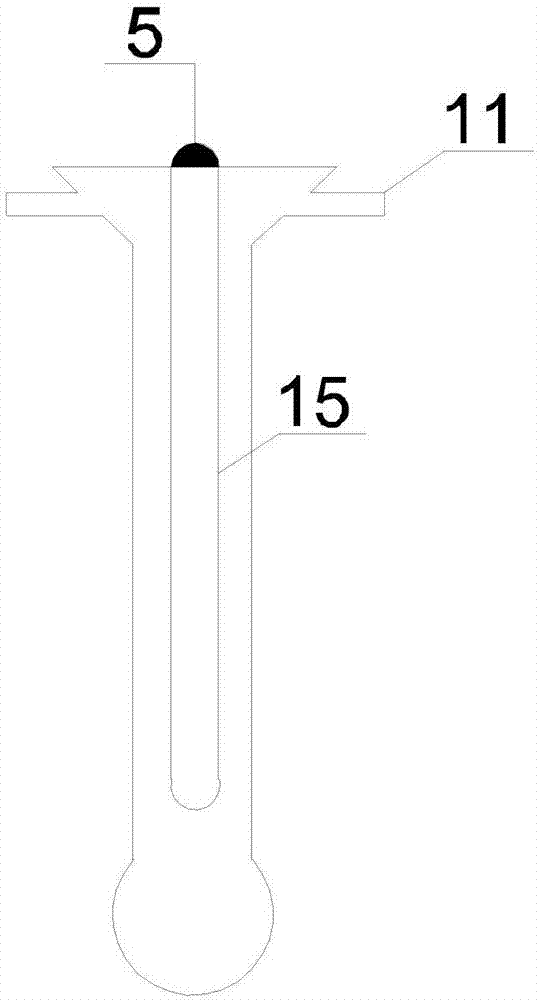

[0024] see Figure 1-4 According to the present invention, the vacuum liquid injection pressurization combined with deep grouting foundation treatment method, the drainage system adopted includes a vertical drainage board 9, a bow tie 8, a horizontal drainage branch pipe 7, a tee joint 12, a horizontal drainage main pipe 14 and a vacuuming device 2, Wherein the vertical drainage plate 9 is connected and connected with the horizontal drainage branch pipe 7 through the bow tie 8, and the horizontal drainage branch pipe 14 is connected with the horizontal drainage main pipe 14 through the tee joint 12, and the horizontal drainage main pipe 14 is finally connected with the vacuum equipment 2. Among them, the vertical drainage boards 9 are arranged in a square, and a deep liquid injection pressurized bag 10 is arranged at the center of the square. The distance between the vertical drainage boards 9 is 0.8-2.0m. The insertion depth of the drainage board is 0.5-1m.

[0025] The liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com