Automatic pole aligning coding sensor

A technology of sensors and magnetic encoders, applied in the field of sensors, can solve the problems that the permanent magnet synchronous motor of the controller cannot be plug-and-play, the controller or the permanent magnet synchronous motor cannot be interchanged, and the increase in manufacturing man-hours, etc., achieves the realization method Ingenious, low cost, effect of reducing installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

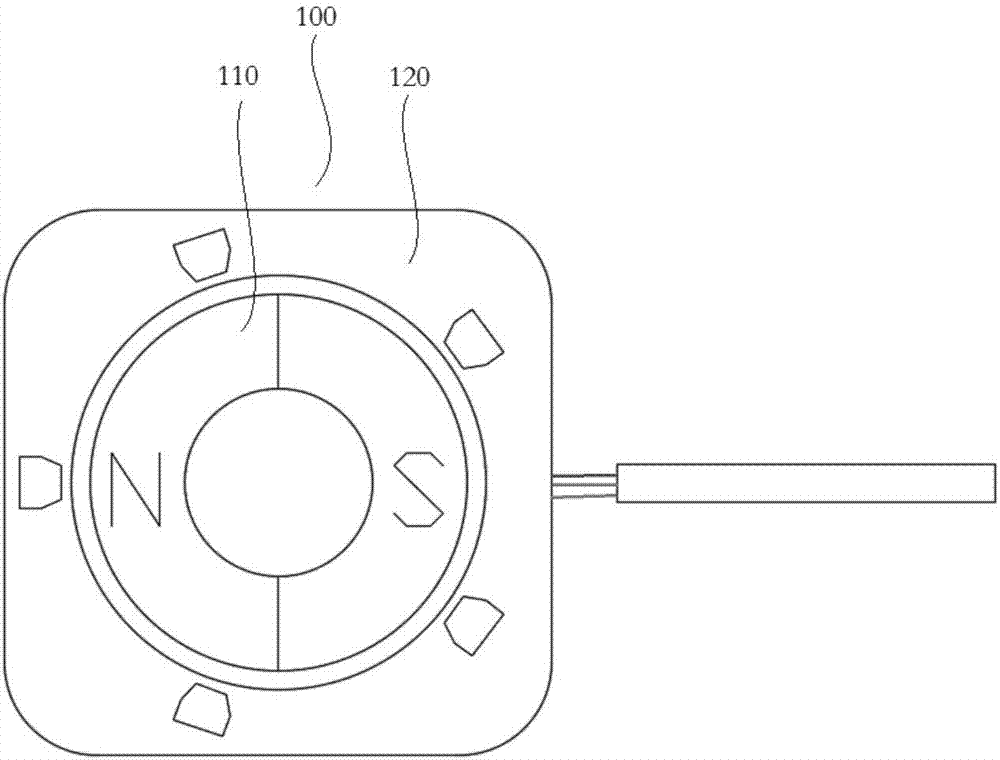

[0032] see figure 1 , which shows the structural schematic diagram of the sensor with automatic pole alignment function provided by this scheme. The sensor is used in a permanent magnet synchronous motor, which can realize automatic pole alignment and accurately detect the rotor position.

[0033] It can be seen from the figure that the automatic pole alignment sensor 100 mainly includes two parts: a magnetic encoder 110 and a sensor body assembly 120 .

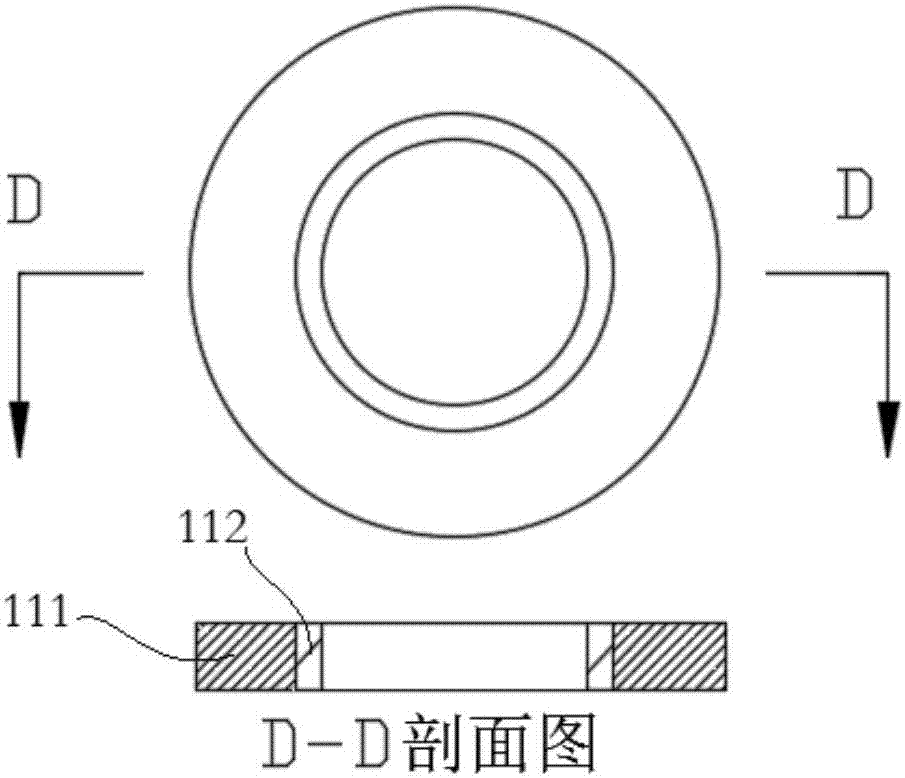

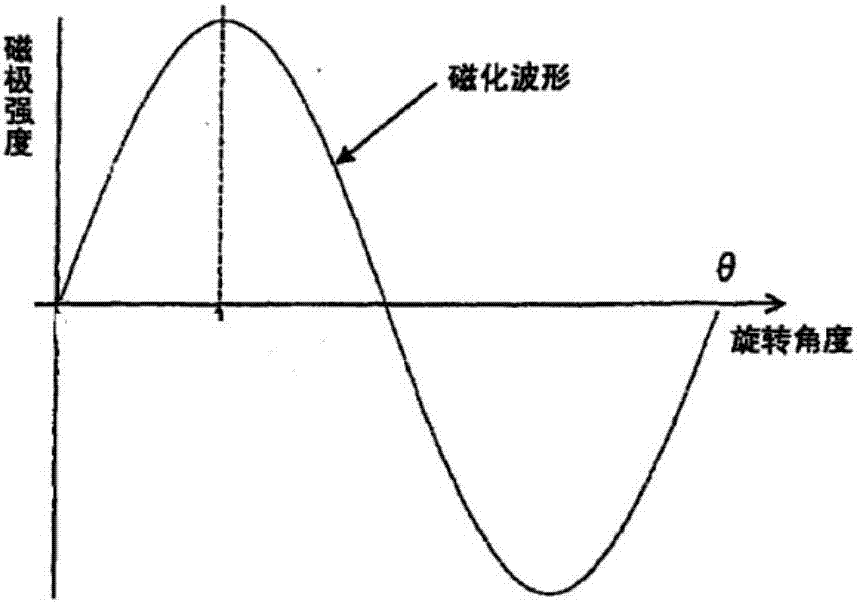

[0034] Among them, the magnetic encoder 110 is used to connect the target object to be measured (such as the rotor in the permanent magnet synchronous motor), which is rotatably arranged relative to the sensor body assembly 120 and generates a continuous magnetic field which changes periodical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com