MEMS fluid density sensor chip based on in-plane resonance and preparation method thereof

A sensor chip and fluid density technology, which is applied in the field of MEMS sensors, can solve the problems of limited density sensor applicable fluid range, lower resonance frequency, poor precision, etc., and achieve good measurement accuracy and sensitivity, reduced fluid damping force, and accurate measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

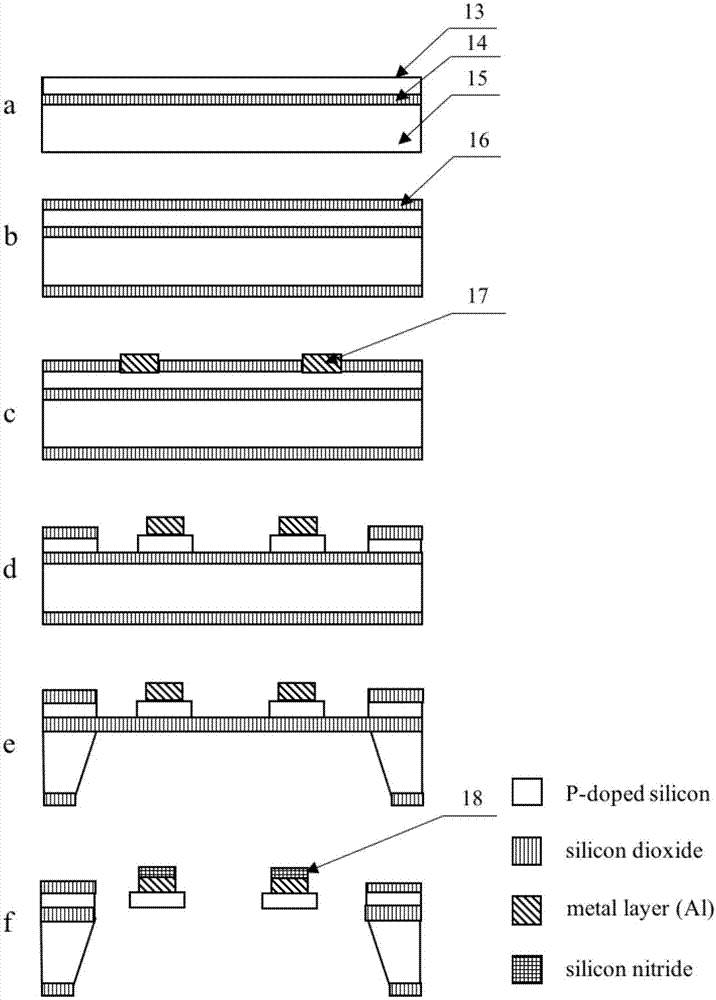

[0032] The preferred implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and through examples.

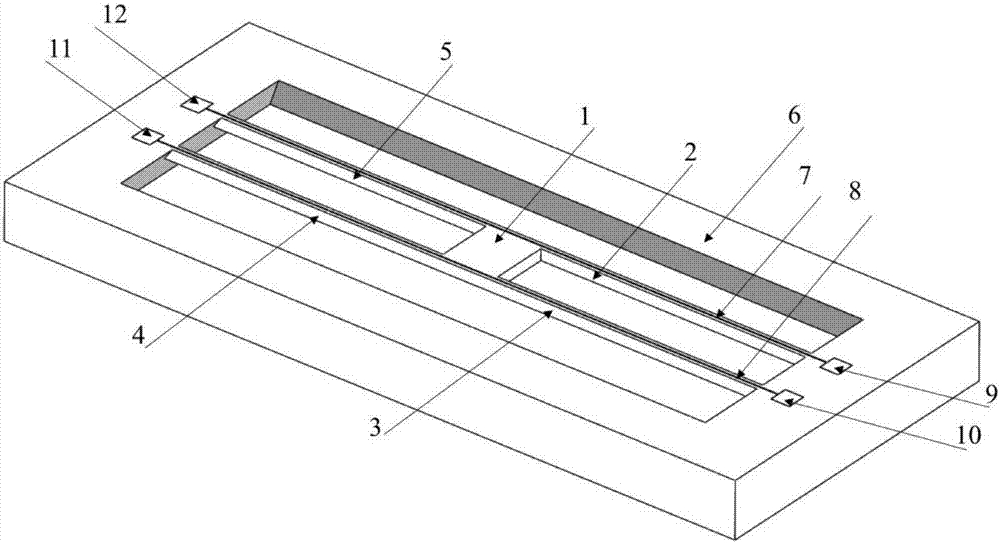

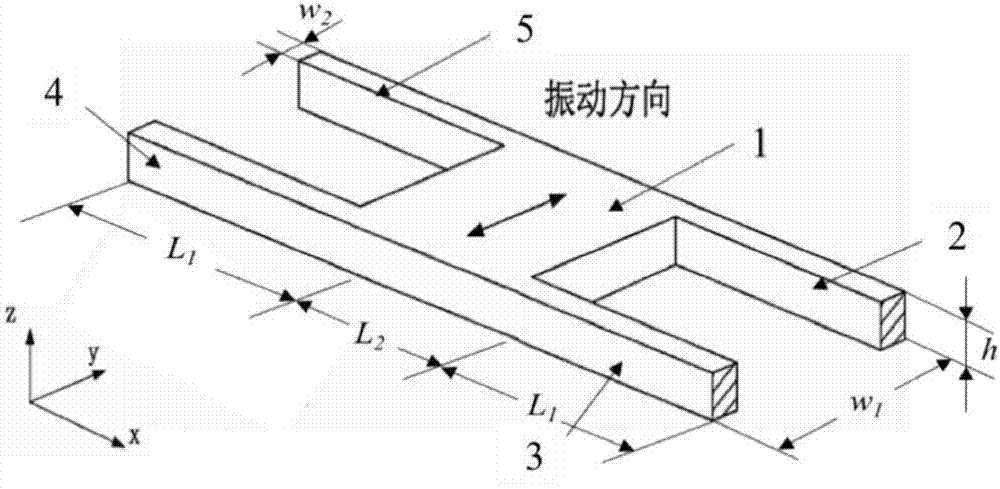

[0033] figure 1 It is a schematic diagram of the structure principle of the present invention. Depend on figure 1 It can be seen that a MEMS fluid density sensor chip based on in-plane resonance in the present invention includes an H-type silicon micro-double-terminal fixed beam structure and a silicon substrate 6 based on the vibration principle; the H-type silicon micro-double-terminal fixed beam structure includes a vibrator 1 , elastic fixed support beams 2-5, wires 7-8, and pads 9-12; the density sensor chip can realize in-plane vibration, and there is a synovial film damping between the measured fluid, which significantly reduces the fluid damping force and improves The measurement range, measurement accuracy and stability of the density sensor.

[0034] A magnet is added to the bottom of the silic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap